Ohio Brass High Voltage Laboratories

Laboratory Number One -- 1910 to 1926

The first laboratory was located in Building 3 at the Ohio Insulator Plant at Park & 9th Streets in Barberton, Ohio. The principle test voltages used at this time were generated by Tesla coils with a frequency from 20 kilohertz to 70 kilohertz because the exact wave shape of lightning was unknown.

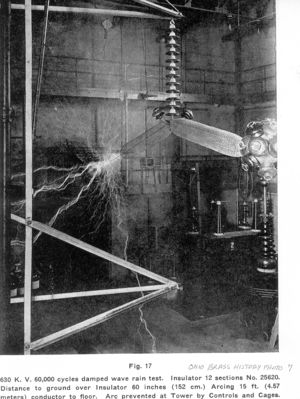

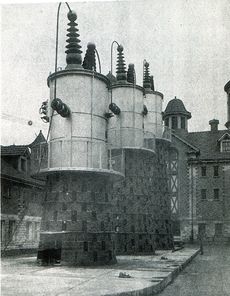

The first photo shows a 12-unit suspension insulator string in a mock tower setting with insulated horns at the bottom of the string and an expanded cage over the conductor. The 630 kv 60 kilohz high-voltage rain test flashes the end of the unshielded conductor 4.57 meters to the floor. The 1.5 m insulator string with insulated horns and expanded conductor withstands the test wave.

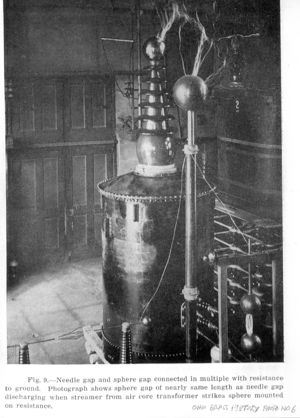

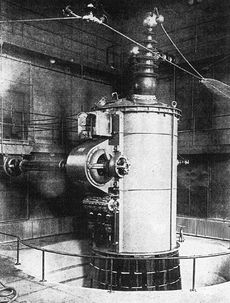

The second photo shows a needle gap in the lower left, seen in parallel with a sphere gap in the lower right with both gaps approximately equal in length and both flashing over from high frequency high voltage. The "air core transformer" may be a Tesla coil immersed in the oil tank shown in the center of the picture with a high voltage bushing mounted on top. The slender column shown in front of the oil tank apparently contains the high-voltage resistor. When the sphere on top of the bushing flashes over to the sphere mounted on top of the resistor column, both the parallel needle gap and the sphere gap are shown flashing over.

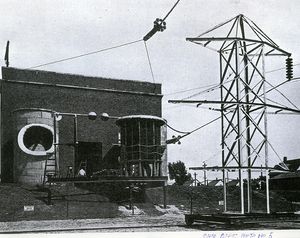

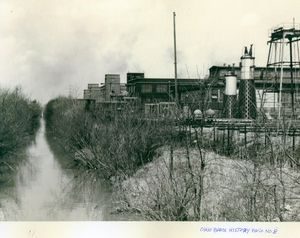

The third photo photo shows the outdoor Ohio Insulator Company's high voltage testing laboratory in Barberton, Ohio. It is shown in Figure 4 of A. O. Austin's June 16, 1925 paper titled "Present use of insulated controls for reducing the number of arcs to ground on transmission lines" presented in Paris, France. This laboratory was located outside Bldg. 3 at the Ohio Insulator manufacturing plant at Park and 9th St. in barberton, Ohio. A. O. Austin conducted most of his high voltage tests at this time using high frequency (10 kilohz to 70 kilohz) voltage generated by Tesla coils as shown in the center of the photo. The top of a transmission tower with a 7 unit suspension insulator string is shown on the right. The function of the two large corrugated silos, one located on the left and one on the right behind the Tesla coil, is uncertain.

Laboratory Number Two -- 1927 to 1933

O. C. Barber, who had made his fortune manufacturing matches, and for whom the town of Barberton was named, died in 1920, but it took until 1926 to settle his estate. In 1926, Arthur Oswin Austin purchased a large tract of land, the mansion, and the horse barn belonging to the estate. The Ohio Insulator Company at about this time (1926-1928) had ordered four 2200 volt to 600 kilovolt 60 hertz test transformers from the Allis-Chalmers company. A. O. Austin found he could over excite the iron cores of the transformers to obtain a new rated average of 2750 volts to 750 kilovolts. A. O. Austin began testing with high-voltage impulse waves generated by charging a large screen wire conductor with the transformer bank and discharging it onto the test specimen. Figure 30 of A. O. Austin's paper entitled "A Laboratory for Making Lightning" presented in Paris, France on 6 June 1929 shows the fourth transformer installed in the Building 3 indoor test lab at the Ohio Insulator plant in Barberton, Ohio. A. O. Austin states that test voltages up to 900 kv were generated.

Laboratory Number Three -- 1934 to 1968

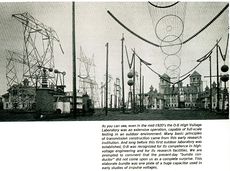

A. O. Austin retired in 1933, and the lower two transformers at the horse barn were moved to the new outdoor high voltage laboratory being constructed adjacent to the Ohio Brass factory in Barberton, Ohio. The indoor transformer could be connected in series with the two outdoor transformers by means of a high-voltage roof bushing. A September 1934 AIEE paper in Electrical Engineering, "A New Laboratory for High Voltage Testing" by J. T. Lusignan and H. L. Rorden describes the new outdoor and indoor laboratories at this site. A new 3000 kv MARX impulse generator was constructed for use in both the indoor and outdoor lab. In about 1960, a new outdoor 4000 kv impulse generator was constructed and many improvements were made. In 1967, high voltage design tests were performed for a proposed 765 kv transmission system for American Electric Power.

Laboratory Number Four -- 1968 to Present

The new outdoor testing laboratory at the F. B. Black Research Center opened in the summer of 1968. The high-voltage bushings on the three transformers were replaced with modern Ohio Brass condenser bushings. The insulated pedestals on which these transformers were mounted consisted of porcelain station post insulators. The 4000 kv impulse generator in Barberton was moved to the new lab in Wadsworth, Ohio, and a new 1000 kv addition was made. This 5000 kv impulse generator with its 3000 kv capacitor voltage divider was used to perform switching surge tests on the proposed 1500 kv double V-string in the large portal tower for American Electric Power.

The IEEE History Center gratefully acknowledges the materials and assistance given by John F. Wiitibschlager, High Voltage Lab Manager 1963-1993, in writing this article

Further Reading

"A New Laboratory for High Voltage Testing" by J. T. Lusignan and H. L. Rorden