First-Hand:Telstar... and some personal recollections

Contributed by: Milton B. Punnett, P.E. (Ret.)

Introduction

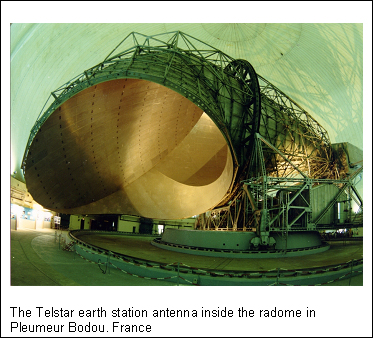

During the time frame of 1960-62, four of the largest air-supported structures ever built were designed and developed as part of the TELSTAR project. Two of the structures were temporary shelters to facilitate the construction of the giant Bell Telephone Lab horn antennas; one in the United States, one in France. These construction shelters were then replaced with equally large (210 ft. dia. and over 16 stories tall) permanent radomes designed to protect the operational antennas during long term environmental extremes. Like the TELSTAR project itself, they represented pushing scientific and engineering capabilities from either a small scale or experimental basis up to an operational satellite communication system.

Following are a few of the writer's recollections from his own involvement in this engineering achievement, which was just a small part of the Telstar project.

The Radome

1960. For today's engineer it's hard to believe how bold the venture was. Our small company was going to build the largest radome ever conceived, using material that didn't exist, requiring joint strengths never achieved, using a new adhesive in a joint design still to be proved. All within a seemingly impossible time period, which left no room for going back. Not only that, shortly after starting, we were informed a second radome would be needed for the station in France. In fact, Goodyear Rubber Co. had told BTL the required lap joints could not be built (which was in contradiction to what Wallie Bird, our president, was claiming) and even several years later (after the erection of a 160 ft. radome in Germany and when the 4th station in Canada was to be built) stated it was impossible to develop adequate joint strengths using the Hypalon radome compound.

The material we proposed for the radome had never been made before and was a hypothetical composite of Hypalon and Dacron (designated as 2D17H70). A new elastomer was selected as it had superior RF properties (principally a lower dielectric constant) than the conventional Neoprene and because DuPont thought it would last longer. (Their technical basis was a garden hose they made out of Hypalon appeared to weather better than any other hose material.)

Credits

When that first picture flashed on the TV screen, I had a tremendous feeling of inner pride. In a sense there was "my" flag and "my" radome. Both the radomes in the United States and in France (as well as the preceding construction shelters) were designed and built by Birdair Structures, a small firm in Buffalo NY, which was an outgrowth of Cornell Aeronautical Laboratories. I would like to recognize Mr. Walter Bird (president of the firm and designer of the first air-supported radome) and Mr Anson Baschmann (materials expert and production manager) each of whom played major roles in the radome project. Mr. George Reitmeier (chief engineer) and Mr. Walter Fowler (design engineer) were both directly involved in the building of the construction shelters. This writer was the project engineer, an all-encompassing title in a small company. I calculated the radome stresses, patterned the envelope, tested the lap seams, developed machinery and fixtures to fabricate the radome, designed the pressure control system circuits, participated in the field erection, and wrote the manual. All of this was under the direct guidance and involvement of Walter Bird. It was his "can do" attitude that made our portion of the Telstar project possible.

Radome Technical Data

Radome material: two-ply, 45 degree bias Hypalon coated Dacron polyester fabric with a total weight of 70 oz/sq.yd. Base yarn hot stretched and heat set Each ply had a greige weight of 17.5 oz/sq.yd.. The woven fabric was scored and dried in a tenter frame to obtain uniform elongation, then calendered at 350 deg.F. Each ply was coated with uncured Hypalon, the plies combined with a bias ply at 45 degrees to the main ply and then Roto-cured. The strip tensile strength exceeded 1000 x 900 lb/in. width.

Electrical Properties: Dielectric Constant = 3.2, loss tan=0.01, t=0.070” Considerably superior to the typical Neoprene/Nylon radome materials of that era. The reported noise contribution of the radome scattering at C band was 8 deg.K dry and 12 deg.K in the rain.

Based upon wind tunnel tests at Cornell Aeronautical Laboratory (CAL) the calculated aerodynamic loads with a 100 mph wind were an Aero. Lift of 844,914 lbs and an Aero. Drag of 221,616 lbs. The lift due to inflation for the 100 mph condition equaled 633,345 lb.

The radome had a surface area of 96,980 sq.ft., and a calculated weight of 90,000 lbs. When folded for shipping it had a package size of 10 ft. x 6 ft. x 40 ft.

Eight heaters were spaced around the base with fabric deicing ducts extending to the crown area. The heaters at Andover had a capacity of 17 x 106 BTU/hr. . The heaters at Pleumer Bodou were rated at 10 x 106 BTU/hr. This tremendous capacity proved to be rather a headache. If simply turned on, the pressure increase from the rapid rise in temperature exceeded the design limits. Consequently we had to add two large pressure relief doors to the intake plenum. Later the Andover site complained about their gas bill.

Making the Lap Joint Seams

The structural joints (intended to be as strong as the base material and capable of carrying 1000 pounds/inch) were to use a new two-part adhesive, which had only been successfully used in the laboratory. It required careful preparation of the Hypalon (typically scrubbing with a wire brush in a bath of toluol) to achieve adhesion. It would have been impossible to practically duplicate the laboratory technique for the thousands of meters of seams in the radome (which has almost 300 panels). Instead we thought it might be possible to carefully remove the oxidized surface layer of the Hypalon coating and then quickly apply a precoat of the adhesive to the exposed subsurface. I saw an ad for a new abrasive material; now called "Scotchbrite" but at that time being developed as a buffing wheel by Behr-Manning. I journeyed down to Behr-Manning's development facility where they showed me a machine with such close control that they could buff off just the ink from a newspaper page. It was impressive but unfortunately the rubbery Hypalon tended to instead snag on the wheel and the coated fabric was not a precise uniform thickness. The result was that sometimes the surface would be nicely cleaned but more frequently the wheel would cut thru the Hypalon coating into the structural base fabric. I thought perhaps we could build some machine where the wheel would travel over the surface controlling the pressure and speed (rather than the thickness). Building such a machine, which actually traveled along the seam line, became a quagmire and I would have given up if it had not been for Wallie Bird's insistence that we must make it work or the whole project would suffer. Eventually, with a little "Rube Goldberg" inspiration, the machine (and several like it) was built. We naturally weren't prone to tell about it and it isn't even mentioned in the technical papers prepared at that time. That may be a reason why for many years Goodyear and other rubber companies continued to say it was impossible to fabricate a high strength radome using Hypalon. Wallie also came up with an innovative lap joint design with slits along the edge to permit a gradual stress loading. It was this concept that he used to sell BTL. Another special machine built in cooperation with Niagara Machine Tool Co. was needed for that. We built large "test logs" (see photo) with these joints and pressurized them up to failure. They were cabled down to some handy railroad ties which usually were flung into the air like matchsticks when the log burst, prompting some concerned inquiries.

Needless to say, the seams proved successful and the most recent tests of samples removed from the radome (after 36 years of exposure) were still OK.

Watching the First Transmission

At the time of the first transmission I was working at the site in Pleumeur Bodou.

Rather than watch on a station monitor, I instead visited a local French family to see how it appeared on their TV...literally at the end of the line. It was obviously a success and after a glass of wine and a toast to the occasion I rejoined the site people to celebrate.

I don't know how Andover, Maine marked the event, but the French party (at the Casino in Perros-Guirec) was something to remember. I personally may have not been quite as enthusiastic as others because we still had to look forward to installing the radome over the construction shelter; a task which had proved sheer agony and almost desperation in Andover. Originally we were to emplace the radome prior to the first operational test but instead we were instructed to delay and the first tests were conducted in the construction shelter, as no one wanted to chance a possible foul-up on our part. Perhaps the Andover experience was a factor. The French crew was probably even more enthusiastic when they heard that the site in England had failed to receive the signal

Pressure System

The radome is held up with air-pressure using 5 blowers, varying from 5 to 10 HP. The pressure is varied as a function of wind speed as measured with an anemometer. As the structural integrity of the radome depends upon this system, it has several alternative sources of power, including the main commercial source, several diesel back-up station generators and a dedicated emergency generator at the radome. . The system must not fail.

In a sense the air-supported radome is a structural achievement entirely and continually dependent upon electrical engineering. There is no structural framework; instead the radome skin or membrane is held tensioned and stable by air pressure. This pressure, which is normally only 1.5" water column (0.05 psi), is supplied by a continually operating electric fan or blower. The pressure is increased with rising winds to maintain the radome stability. The control system selects higher pressure blowers in response to the wind speed signal. It also switches on additional blowers in case of a pressure loss or a blower failure and sequences loading if a power failure results in transfer to an alternate source. The system incorporates fail-safe and redundant circuitry.

When I confessed to Matt Grubilich at BTL that I was having difficulty in designing the control circuit logic to handle the many different combination of conditions with maximum reliability and not overload the power supply while starting the motors, he suggested that AT&T had plenty of experience in designing reliable switching circuits and that I should immediately fly to New York City where he would arrange for one of their top designers to assist me. In one day we went thru scenario after scenario continually revising the circuits. It was a real learning experience and to this day the pressurization systems of modern air-supported radomes reflect those lessons.

It has always amazed me that visitors to a Telstar site would seemingly be most impressed with the radome and the fact that it is held up only with air. When I would point out the complexity of the giant 360 ton antenna sitting inside, they would again ask "What did you say holds up the radome?".

A major portion of the operation manual is devoted to the pressurization system.

The Constuction Shelters

The dependable performance of the final radomes is anticlimactic to our experience with the construction shelters. The shelters, actually radomes in themselves, were needed to permit the assembly of the antennas under inclement conditions. They were produced on a very short time schedule using the strongest commercially available material. We computed they would only withstand winds up to 60 mph. Sure enough, when the wind at Pleumeur Bodou reached 60 mph the shelter failed. An overly hasty repair attempt also failed and it was eventually necessary to replace the shelter with the unit previously used at the Andover site. In addition they were used to emplace the permanent radomes over the completed antennas; a process described by Electronic Design magazine as a giant equivalent to the magician's trick of removing someone's shirt without taking off their coat. As both the shelter and the radome were the same size it was necessary to lower the shelter to an attachment line above it's equator. The radome was then floated over using air and a multitude of cranes.

The Blister

Because of the tremendous size of the antenna, the construction shelter needed to be as large as the radome. In order to fit over the antenna when the shelter was lowered, it was necessary to include a 50 ft. diameter "blister" on the shelter, which would fit exactly over the upper equipment room on the end of the horn. It would then have about one foot of clearance. In the very early stages I had to compute the location of this "blister" using only preliminary data as the actual antenna drawings were far from complete. In some of the photos you can just see me on the top of the equipment room with the blister lowered in place.. Needless to say I had a great sense of relief that it fit.

After the construction shelter was removed and scrapped, we cut the blister off and sold it to Sanders Associates to use as a test facility radome.

If you look closely at the large photo of the antenna in the museum brochure and on their web site, you can tell the picture really doesn't show the radome but was taken in 1962 inside the construction shelter, as the blister is just visible behind the antenna.

Shooting the Shelter

During the winter a heavy wet snow fell on the construction shelter in Maine. The heating equipment had not been completed and the shelter could only be pressurized to a fraction of the peak levels used in the radome. Consequently the crown area (which was bigger than any previous design and appeared almost flat) collected snow. As this snow melted it began to concentrate in the center resulting in a "dimple" with a large pond of water. Wallie Bird suggested they shoot some holes in the shelter to drain the water. It worked; but when the shelter popped back up into shape the remaining snow and slush slid over the side in an avalanche, landing on top of the site field office trailer. Fortunately no one was inside as the office was completely flattened. Not long after that I was on an airplane flight chatting with a stranger sitting next to me. We were discussing our jobs and I mentioned this incident. He then told me he was in the business of renting construction equipment and it was his trailer that we had destroyed.

Getting to the Top

When the construction shelters were being built we didn't take time to think that perhaps it might be necessary to reach the top. When the Maine site called to say that a small tear had appeared in the crown area, we rushed to the site. We knew it had to be fixed or risk total loss. We thought it might be possible to rig a rope line over the shelter to hoist someone up. At first we called a local archer with a powerful hunting bow and had him try to shoot an arrow trailing a light string over the top. The arrows just bounced off the side. We then called the Coast Guard who arrived with a Breeches Buoy gun (used for ship rescues). Even with the largest charge it couldn't go over the top (he did reach the blister). Next was a small helicopter with the pilot dangling a rope. We held the end and, as he tried flying over, the line accidentally twisted around my technician's (Jack Little) hand. The pilot felt the yank and threw out the coil of rope. It then got tangled in his landing skid. We literally pulled the copter down, with the pilot white as a sheet. He cleared the gear and took off, leaving us standing there and Jack with a broken finger. A call back to the Coast Guard brought a big Air-Sea rescue helicopter. They in turn tried to lay a rope over the top. This time we didn't hold the end, but instead they kept dropping the rope out in the woods. Finally BTL pulled some more strings and got the biggest crane in Boston taken off a site and trucked up to us, complete with police escort. The crane had a 240 foot boom and required another small crane just to put it together, but it got us to the top.

Getting to the Top... again

Given the problem with the construction shelter, we decided to include a small man hatch in the aluminum crown plate of the final radomes. A small "trapeze" platform was suspended on four 1/4" cables below the plate. A boson’s chair could be hoisted to reach the platform using a rope and pulleys with a hoisting crew below. When the chair reached the top it was necessary to slide backwards off the chair onto the swinging platform. We rigged a mockup of this arrangement from our shop ceiling and tested it. I found it to be rather shaky and unstable but, figuring I would never be the one who would have to use it, pronounced it OK. (I did add a caution in the manual that the person using the chair "must be agile”.) Unfortunately, once the radome was erected, only Jack would agree to go up; and only if I did it first. It was much more disconcerting to do this trick hanging in free space 160 ft. above the ground. To top it off, when coming back down, the hatch was so small I couldn't see below me and, even while hanging by my armpits, my feet couldn't reach the platform. It took a bit of faith to just let go. Later, while inspecting the French radome in 1968, I again had to use this rig in order to retrieve some exposure samples. We had strung a rope down from the crown plate alongside the chair, figuring that if the chair lines got tangled it would be possible to slide down the rope. I blithely held on to this rope while being hoisted up. On getting to the top I found the end of the rope was merely lying on the plate and tied off to nothing. The entire scheme was eventually abandoned.

A Close Call

Shortly before the scheduled transmission of the first signal, the main slip ring assembly of the Pleumeur Bodou antenna failed(2).

Ken Woodard's group from BTL had a spare assembly back in the United States, but there was no way it could be shipped to the site in time. Instead the French electricians (who were masters at improvising) jury-rigged a series of cable loops to bypass the rings. It worked, and the antenna was on the air at precisely the right moment. This may be the first case of a large antenna using twisted cables rather than slip rings, a common practice in modern Sat-Com parabolic dish antennas.

(At one point I shared a room at the French site with Ken; I envied his group, as I couldn't imagine a better boss, even though technically he was our customer.)

Politics

In today's era of privatization and mega-mergers it's hard to believe that in the 1960's the U.S. government would not allow AT&T to continue it's effort in developing a satellite communications system. And that a few years later a federal judge's ruling would result in the destruction of Bell Telephone Laboratories as it then existed, probably the premier electrical engineering research and development facility.

Sequel

In 1979 Chemfab Corporation acquired Birdair Structures. In 1998 France Telecom inquiring as to how much longer the radome at Pleumeur Bodou might continue to serve contacted Chemfab. Consequently a small task group was established to inspect the radome and to remove specimens for laboratory analysis. The writer, accompanied by Mr. Jim Greno (Chemfab's communications products manager) revisited the site. It was most impressive. A surprising aspect was the response of the local newspapers and TV in announcing the return of "le papa du Radôme". For a brief moment I was a celebrity. The radome was found to be in excellent condition far exceeding our original design expectations.

Seeing the original antenna and radome preserved as a telecommunications museum inspired me to suggest that the IEEE acknowledge Telstar as an engineering milestone. That suggestion was accepted and I embarked on preparing the documentation needed for the recognition. Although the Andover facility had been dismantled, the town agreed to a plaque in the town square. The English site soon requested that they too be included in the recognition. The site in Pleumer Bodou had already been designated a French historical site and they enthusiastically joined in the recognition.

A further honor came in the year 2000 when a French millennium calendar selected the radome as the outstanding architectural structure for the 1960’s in the Cotes d’Amor. Even more surprising was that it listed me as the architect.

References

1) "TELSTAR communication break-through by satellite", Louis Solomon, 1962- 65, McGraw-Hill Book Co.,NY

2) "Le CNET et les Telecommunications Spatiales", Regards sur la France, Num. 17- 18, Jan-Avr. 1963, Paris France

3) " The Mechanical Design of the Horn-Reflector Antenna and Radome", Dolling,Blackmore,Kindermann and Woodard, The Bell System Technical Journal, Vol.XLII, No.4, July 1963, U.S.A.

4) "TELSTAR OPERATION AND MAINTENANCE MANUAL" , Birdair Structures, Inc. October 1963,USA