First-Hand:Philips Telephone Exchanges and Denmark, 1960-1970: Difference between revisions

No edit summary |

J.vardalas (talk | contribs) m (First-Hand:Philips Telephone Exchanges and Denmark moved to First-Hand:Philips Telephone Exchanges and Denmark, 1960-1970: Author asked that title be amended) |

(No difference)

| |

Revision as of 15:52, 9 March 2009

December 1960: ”I never dared sell that”

During the trip when an agreement with JTAS was made to supply the test exchange ETS 3 to them, Reinders, who was sales manager at PTI in Hilversum, said: “The only telephone system I ever understood is the manual Magneto system. And that is as well. If I understood the complicated systems we make today I am not sure I dared sell them”.

About this time, Pierce, who was head of the Bell laboratories in the USA, made a statement comparing computers and telephone exchanges. One must remember that computing at that time meant batch processing, i.e. data and programs were prepared on punched cards, carried to the computer, read-in and processed, whereafter the result was carried back to be post-processed. It was quite a while before terminals at a distance became a rule.

Pierce said that the difference between computers and telephone exchanges was that in a computer a calculating error was a catastrophe while a total break-down was a minor nuisance. In a telephone exchange it was just the other way round.

A calculating error in a computer may result in a wrong bank-statement or a wrong salary payment, and that is a catastrophe. In a telephone exchange it would normally only result in a wrong number, and then you just apologize, goes on-hook and makes a new call.

A break-down in a computer would be repaired and the stack of punched cards read in again, only resulting in a minor delay of the result. But when a telephone exchange breaks down it is impossible to call police and ambulance. The customers must have the assurance that the exchange is always ready to serve them.

March 1961 to October 1963: ETS 3 development

During the trip to KTAS and JTAS in the end of 1960, when a final agreement was made with them on supply of ETS 3, de Kroes, head of development of exchanges in Hilversum, asked me again whether I would move to Holland and take part in the development of the exchange?

I discussed it with my wife and as the housing situation was still bad in Holland we agreed that we could accept, provided the Dutch found us a flat and Philips paid all extra expenses in connection with the move. Otherwise we had no special conditions like an allowance for being away. It should be just as a continued employment in Copenhagen.

The result was that I continued getting my salary in Copenhagen. Then special items like pension payment could continue unchanged. I had what we needed for our daily expenses transferred from my Danish bank-account to a Dutch one.

The condition about extra expenses turned out to be very lucky. It appeared that a flat in Holland is delivered to the resident in a quite other condition than a flat in Denmark. When we could finally move in (2 months after we had come to Hilversum) we found a flat with concrete floors, with no heating and no major kitchen utensils except for an absorption refrigerator (which the builder must have got at a very low price!). But Philips paid for wall-to-wall carpets, an oil stove, a range and a water-heater, items which were part of a Danish flat and which would therefore be unnecessary for us when we moved home. It would be the headache of Philips at what price they could pass them on to the next inhabitant.

As for the refrigerator we were glad to have taken our own, with a compressor, with us from Copenhagen. We did not use the one with the flat much.

Construction of ETS 3

How was ETS 3 constructed? I shall here only provide a short description, with weight on the persons responsible for the individual parts. A more technical description is found in an issue of “Teleteknik” from early 1968.

The exchange had no. 3 because there were two predecessors. ETS 1 had been built in the laboratory and was demonstrated for KTAS in January 1959. ETS 2 was a paper project to evaluate whether Philips could on basis of ETS 1 make a saleable product. The result must have been positive, for as a result ETS 3 was made.

But it did not result in a saleable product. For one part, other systems were further developed, for another so much extra was added in order for ETS 3 to function with the usual reliability required in telephony. Another requirement was that it should be possible to keep it in operation and adapt it to changing user requirements for a crew of typical exchange technicians and operators.

The core amplifier

First a word on the exchange components. The logic circuit the whole control was made around was like in the metering equipment two years earlier the core amplifier. It was still the only component which had proved its reliability in professional equipment. Remember that we are still in a period about 10 years after the invention of the transistor, so almost all statements about their lifetime were very loosely based. In general one could only test their longevity under overload and hope that when one in operation loaded them 10 times less, they would live 10 times longer than when tested! Naturally data from actual use were also collected but there were not much experience to draw from as yet.

The core amplifier consisted of a germanium pnp-transistor and four ring-shaped cores. The emitter was connected to ground (0 Volts). The base was via a winding through all cores connected to +2 Volts. The collector was via another winding through all cores connected via other core amplifiers and a resistor (120 Ω) to –24 Volts. Two cores had a third winding with a bias current so they were always kept in their one-condition (except when the core amplifier fired), the other two had some windings through which they could be set to their one-condition by current from other core amplifiers (normally as an and-function, current had to come simultaneously from two sources) and a winding for reading the state of the core amplifier. If it was in the one-condition when the latter winding was energized the base winding would ensure that the transistor would conduct. Now the collector current would give a positive feed-back to the base winding so all four cores were reset properly to their zero-condition. The base voltage, the number of turns on the base winding and the flux in the four cores controlled the duration of the collector current, the resistor limited it to 200 mA. Then current pulses from other core amplifiers might set the two last cores again, while the two first ones had been set immediately after read-out by the bias current.

The whole core amplifier was embedded in epoxy resin and was a block of about 5 cm by 3 cm by 0.5 cm.

The core amplifier had a serious draw-back: it was slow! It was used in circuitry with four phases, i.e. each core amplifier could only be read every fourth clock pulse, and each of these intervals lasted 50 μs, 25 for the pulse and 25 for the pause before the next pulse (which sounds like a long time, but pulse from one core amplifier could trigger a pulse from the next etc., and in the worst case the last pulse should have ended before the next clock pulse). Thus a new cycle started only every 200 μs or 5000 times a second.

This implied that ETS 3 had to be built up in a quite modern way, namely in individual modules for each its separate task. And all these modules had to work in a coordinated fashion.

Thyristor as crosspoint

The other important component was the electronic crosspoints in the selectors, over which speech would pass when they were on. Each contact was a Germanium pnpn-transistor or thyristor as it was later called. It worked as a so-called hook-switch of a pnp and an npn-transistor in combination. Imagine that the emitters are available as the two terminals of the switch and that the base of one transistor is connected to the collector of the other. Finally there is a high-ohmic control connection to the base of the pnp-transistor (and collector of the other). In the idle condition the switch is off, as none of the two transistors draws base-current from the other. The switch goes on when the control connection goes briefly negative. Now the pnp-transistor supplies current to the npn-base, the npn-transistor draws current from the pnp-base, and both are soon saturated. The control current may be switched off, but the two transistors will remain saturated with a small resistance as long as current flows through them. They return to the idle state as soon as this current is interrupted.

The thyristor had of course also its draw-backs. First of all the sustainable blocking voltage between emitter and base (of the pnp-part) was too small. This was dealt with by putting a diode of the type OA 5 in series with the emitter, so the diode provided the blocking. But it meant also that a rather large DC-current had to pass the crosspoint when it was on, in order that the speech-current on top of the DC-current should not be distorted by the non-linearity of the total DC-characteristic of diode and thyristor. Thus the whole crosspoint consisted of a diode, a thyristor and a 27 kΩ resistor to the base for turning the thyristor on, all kept together by a rubber-band. There were about 15000 such crosspoints in the exchange. The rubber-band caused problems after several years of operation.

Another draw-back was the price of the crosspoint. This implied that there could be only one crosspoint, one contact, for each point of the selectors, where from old the balanced connection over a twisted pair in the telephone cable was continued through two contacts for each selector point in the exchanges. We had to have an unbalanced connection through the exchange with one contact per crosspoint and ground as the common return path of all calls. And there had to be a transformer for the conversion between balanced and unbalanced transmission at each end of each path through the exchange. The common return must of course not give any crosstalk from one call to another. Therefore we made all connections between two selector stages two-wire, with one wire to ground in each end. Between two of the stages we even put a transformer in series with the wires, so the speech current in one wire would cause an equivalent but opposite current in the other. All in all we succeeded in having as little crosstalk in ETS 3 as in the electromechanical exchanges with which it was compared.

The selector network

In a telephone exchange all cable pairs to the subscribers are connected to one side of the selector network and all the circuits which serve during calls are connected to the other side. The individual subscriber uses his telephone for only a few minutes per hour, even during the busy hour in the forenoon, and therefore the number of servers is far less than the number of subscribers, e.g. one server per 10 subscribers. The selector network will provide a connection between a calling or called subscriber and a suitable server.

One could imagine such a selector network as a large crossbar selector, with all subscribers along one side and all servers along the other. From each subscriber and from each server a speech path goes through the selector. At each crosspoint between these two speech paths a contact can be made between a subscriber and a server. With 1000 subscribers (as in ETS 3) and e.g. 100 servers there should be 100,000 crosspoints.

This is a very uneconomical construction. Crosspoints can be saved by bundling subscribers in small groups on a first stage in the network, e.g. groups of 20 with 5 connections from each group to the rest of the network. With 1000 subscribers this would claim 50 groups with 100 crosspoints each or 5000 crosspoints in the first stage. There will then be only 50 times 5 or 250 connections to the rest and with 100 servers in a large crossbar switch this would require 25000 crosspoints. Thus the total number of crosspoints is reduced to just 30000 in one go. But in every group of 20 subscribers there are of course only 5 who can be connected simultaneously to a server.

One can go on like this. In ETS 3 there were four stages of crossbar switches between subscribers and servers and a total of about 15 crosspoints per subscriber. The connections between stages were called links and of these there were about one per subscriber. A control circuit called linktester/marker found free links between a subscriber and a suitable server and ordered the crosspoint contacts to switch on.

The thyristors were switched on with a voltage between their emitter and base and they were held on by the current through them from emitter to collector (corresponding to the npn-emitter in the hook-switch). In the crossbar switch the input link was connected to a row of emitters and the output link was connected to a column of collectors. The marking connection to the bases of the thyristors was parallel to the columns. On marking there was only emitter marking voltage at one input link in the whole exchange and the correct column could therefore be indicated in all selectors of the relevant stage simultaneously.

The linktester had a connection to all links between the selector stages. When a connection through the network should be made the linktester asked directly on the links whether they were free or busy to find a free path between subscriber and serving circuit. This implied that a separate administration of the links was not necessary, and that meant again that when a call ended the server could just cut the current holding the thyristors, no message to a link administration to note the used links free was required. This implied also that the reliability could be supported by a duplication of the control circuits where the spare was quiescent (was in cold stand-by) and in the moment it should take over the operation knew nothing about the conditions in the selector network.

A couple of draw-backs compared with electromechanical selectors: One was the attenuation through the exchange. There was a larger resistance through the diodes and thyristors and the balancing transformer in one of the links than through a similar number of mechanical contacts. There was also the leakage current through the base resistances and the linktester connections. All this because the control was done over the same devices as the speech-path used. Our attenuation was about 2 dB, where the old exchanges had less than 1 dB. We were allowed to have this attenuation, but only for a test exchange. There would be no slackening of the requirements if we later used these principles in a commercial exchange!

Another was that the link-testing and the marking process inevitably influenced the speech path. This gave very narrow bounds on the current and voltages allowed, as we naturally had to work within the permissible limits for noise on the speech path.

The selector network with its surrounding circuits for switching the holding current on and off, for separating DC and AC and for connecting its parts to the control circuits was constructed by J. Blom, while the lay-out was made by W. Milort.

M. J. Schmitz

The description has already changed from components to larger system parts. Before going on it would be correct to say a few words about M. J. Schmitz who was head of the ETS 3 development team.

Schmitz had been earlier employed in the Dutch telephone administration (PTT) and was one of the few examples at that time of a person who reached a leading position in Philips Telecommunicatie without being an M.S.E.E. He was qualified in this job and had a nice manner towards us in the group. That he was under quite some pressure from higher up to provide some results and gave in to them was understandable. One version of Murphy’s law which applied very much to Philips then was: “There is never time to do it right, there is always time to do it over”.

I knew Schmitz from my first visits to Hilversum in 1959 and later and met him again as I was in Hilversum in January 1961 and he showed me around in the house where Philips had found us a flat. It was still being built and had long ladders around it. I asked the builder whether it would be ready when we arrived on April 1st? He answered very precisely that no, it would not be ready by then. In my innocence I was sure that it would then be ready April 2nd, but that was my error, nobody had said so! Actually we could move in on June 1st.

Later we also visited the Schmitz family privately. They were brillant when our first daughter was born, really felt with us and helped my wife.

A couple of events: Schmitz told that he had almost been lynched in Amsterdam in early 1945. It was a time with many rumours. The Hunger Winter plagued Holland north of the rivers (not because the Nazis would starve them to death, but provisions could only arrive through the narrow passage via Utrecht as all land south of the rivers had been conquered by the Allied (remember the film “One Bridge Too Far” on the action to push forward to northern Holland in September 1944). And now there were rumours that the Allied had dropped parachuters in northern Holland and had conquered the town of Groningen. Schmitz came out of the PTT building and heard the rumour. He had talked with a PTT employer in Groningen the same day and could tell that the rumour was utterly false. People thought that when he could talk with people in the other end of the country he had to be a Nazi helper and would attack him. He escaped. One more example that it can be unhealthy to bring bad news!

Another event showing his fast mind: We were with Buchner (another head in the laboratory) on our way to a meeting at the PTT in The Hague in Buchner’s car, an Auto Union like mine. Schmitz had an Opel Rekord. On the way we met another Auto Union and Buchner flashed the lights as a greeting as was so often done between these cars. And said to Schmitz that such an enthusiasm was not seen among Rekord owners, they never flashed. Schmitz answered that if he should greet all the Rekord cars he met every day he could as well light up the headlamps as soon as he left his garage and keep them on!

Schmitz was not to see ETS 3 in operation. He died from cancer early in 1966. I do not know how much was due to the delays and constantly postponed terms we experienced in the development of the exchange, but they must have had an effect.

A couple of Schmitz’s expressions made our collaborators from KTAS and JTAS laugh, as it was so obvious what they meant. The delays were unpleasant for them as well and Philips had to announce them and other items in a soft way so they were acceptable for all parties. At these occasions Schmitz always started in one of two ways. Either he said that he had just had a brainwave which he would like to discuss, or he began “Speaking in black and white” and then came what he meant to say.

Control circuits on the subscriber side

Back to the modules of ETS 3. Above the middle of the exchange is described, the selector network, the linktester with its threads to all links between selector stages and the marker with its threads to the base resistor of each and every crosspoint.

On the subscriber side the selector network ended in the subscriber circuits, LC. These were constantly scanned for new originating calls by a subscriber scanner, AO for Abonnee Onderzoeker. And the AO reported the new calls to a subscriber memory, AG for Abonnee Geheugen.

The LC had primarily the components for the connection of the cable pair to the subscriber and the path through the selector network. There was a transformer for the conversion from the balanced transmission on the cable and the unbalanced transmission in the network. In addition the transformer separated the DC on the cable pair and the DC in the network. The latter held the thyristors on during a call, the former supplied current to the telephone sets at the other end of the cable pair (the subscriber loop).

On the network side one end of the transformer was connected to ground, the common return path for all the connections through the network, the other end to the thyristors of the first stage in the selector network. This path included windings on two ring-shaped cores of 2,5 mm diameter, called the M3 and M4 cores.

On the cable side the transformer winding was divided in two, with a capacitor between them and the cable pair connected to the other ends of the windings. Plus (ground) and minus ( 48 Volts) were fed via two resistors of 400 Ω each to the two sides of the capacitor. In addition the DC passed through windings on two of the usual cores, called M1 and M4 (the latter was mentioned above).

It was arranged that the DC on the two sides of the transformer were in opposite directions to reduce the total DC magnetization of its core.

A subscriber connection is supervised by detection of the DC going to the telephone set. When the set is on hook the DC is interrupted, when it is off hook the DC flows. In addition dial pulses are short interruptions of the current. Normally occurring at 10 pulses per second, but in Denmark up to 20 pulses per second was used, i.e. interruptions of down to 16 ms. The M1 core was set by the DC and reset from the AO, and its output was read by the AO. But the AO should not scan the LCs fast enough to detect dial pulses, only to detect new calls. Detection of dial pulses was left to the relevant servers and in order to transfer information on the DC state on the subscriber loop the M4 core was set by the loop current, reset by a 20 kHz pulse train and its output injected in the path through the selectors via the winding on the selector side mentioned above.

When a caller starts a call there is ample time to detect the loop current. It takes about half a second for the handset to reach the ear and this time is therefore available. The AO only scanned fast enough to detect new calls. If the AO should have detected dial pulses it would have had to scan all LCs every 5 ms, which had been impossible, or scan those LCs which were in a dialling state every 5 ms, which would have implied a constant jumping back and forth among the LCs and was therefore also impossible.

There was also an M2 core in the LC, set and reset by the AO and with its output read by the AO. Whenever an M1 core was read and gave an output the M2 core was set. Thus at the next reading both M1 and M2 gave an output and the AO knew that this loop current had been detected.

Finally the M3 core. It was set by the DC through the thyristors, reset by the AO and its output was read by the AO. Whenever there was an output from the M3 core the AO knew that the LC was connected to a server and was supervised by it. Thus the AO could ignore all other signals from the LC.

The AO scanned as said all LCs and detected the output of the M1, M2 and M3 cores. Every LC was scanned about 10 times per second. The logic circuits of the AO treated the signals as such:

• If output from M1, M2 was set.

• If output from M1 and no output from M2 or M3, the AO reported a new call to the AG, with the identity of the LC.

• If output from any core when the AG ordered the AO to detect the state of an LC the answer to the AG was that the LC was busy.

The last point happened when there was a terminating call (a call to the subscriber) and it should be decided if the caller should have a connection or a busy tone. When the AG had ordered the AO to jump to a certain LC and read its state the AO continued its scanning from that LC.

In this way it was ensured that each new call was only reported once to the AG, and there was a line blocking which only made the LC itself busy. Assume e.g. that a handset was taken off hook and placed beside the telephone set. It was seen as a new call and a path through the selector network to a digit receiver was set up and the digit receiver sent dial tone. If no digits were received the digit receiver would give up after about 20 seconds and change to sending busy tone. After another 20 seconds it would give up completely and release the connection through the network. Now none of the common servers nor any crosspoint were busied any more and the output from M1 and M2 would ensure that there was also not reported a new call. This was a silent line blocking (without tone signal) and when the handset was placed on hook the M1 core would be left reset after the next scan of the AO, the M2 core after the scan after that. Thus after about 200 ms the LC would be ready for a new call, originating or terminating.

The largest problem for the AO was that all the M1, M2 and M3 cores were spread over a whole cabinet of LCs. The signal to be detected had an amplitude of about 0.1 Volts so it could easily drown in noise. The detector circuit had the two ends of the output wire through the cores connected to the emitters of two transistors. Each transistor had its base connected to ground through a large electrolytic capacitor. Thus, a proper output would appear as one emitter going positive, the other going negative, i.e. one transistor conducting more and the other less. The detector amplified this signal to provide an input to a core amplifier. A common mode noise signal would make both emitters go positive or both go negative, or make the conductance of both transistors change in the same way. The problem was that this only worked for noise voltages of less than 0.2 Volts or the transistors were driven into blocking or saturation and inevitable differences between them would cause an output anyhow. Fine for a detector with a short detector circuit, but bad when the circuit went through a whole cabinet!

I had read an article on this topic and suggested that the two capacitors should be connected in series between the bases of the transistors, with a resistor of several kΩ between their common point and ground. In this way a balanced signal would give the same (wanted) result as before, while the effect of a common mode signal would be suppressed. It was tested and worked perfectly. But a thorough investigation in another group was denied, they had developed the detector we had to use already. In stead we had to route the detector wire carefully to avoid common mode noise. I suggest that it was the NIH (Not Invented Here) syndrome in action!

New calls were reported to the AG, the subscriber memory. It was constructed around a large memory with data on the subscribers. There were about 40 cores for each of 1152 subscribers or a total of 45,000 bit. This took up a whole shelf in ETS 3! The first 1000 addresses corresponded to the 1000 telephone numbers (directory numbers) of the exchange, the last 152 to lines under hunting groups, i.e. lines to PABXes and the like in the 1000-group. Data for each address were to which LC the number was assigned (there was free numbering in the exchange), metering pulses collected, next number in a hunting group and some characteristics like “only originating calls”, “only terminating calls”, “subscriber meter”, “message service”, “no payment” and the like. Data could be changed from a teleprinter and one was placed in the operator room in Århus so the operators could switch message service on and off for the subscribers of ETS 3.

The addressing was by directory numbers in order to give an answer quickly to the program memory or PG (for Program Geheugen), the coordinator of all the control circuits of the exchange. When a terminating call was made the PG provided the directory number with a request whether it was free? The AG could use this number as an address and read the LC number, send this number to the AO which again could use the LC number directly as an address and answer immediately with the actual state of the LC.

In case of an originating call the AO reported it to the AG with the LC number as additional data. In this case the AG had to scan its addresses until it found one with the same LC number. This address was the corresponding directory number and the AG could inform the PG about the new call with all data necessary for its handling. This scanning took time but as said there was time until the subscriber had the handset by the ear.

There are, however, subscribers who have the handset by the ear already when the public exchange is called, such as users under a PABX. They would sense the waiting time. To cut this time the last 152 addresses in the AG where all lines in hunting groups were placed were always scanned first when the AO reported a new call.

LC, AO and AG were developed by Jan de Ruijter and A. Hiele. I shared for a long time office with de Ruijter and he lived close to us in Hilversum so we met also privately with our wives – who also saw each other quite often while we were on work.

There was a bad moment in 1965 when the AG should be connected with the rest of the exchange. Nothing worked as intended. Why? Because there was a pressure on de Ruijter a couple of years before to quickly produce the drawings so the factory had material from which to produce the AG. He had directly drawn up how the components, the core amplifiers, had to be connected and had drawn lines around those which should be in the same plug-in unit. Without a general view of how the AG should operate. Then W. Smit was called in and he first drew the function in flow charts before this was translated to components. And then it worked!

Special telephone sets

It was important to keep the total price for LC and subscriber installation as low as possible. A normal telephone is called by a ringing signal which is a rather heavy AC current. This signal could not be sent via the crosspoints in the selector network (nor could it pass the transformer in the LC – the frequency was 25 Hz and thus far too low for it). One possibility was to connect this signal to the subscriber pair in the LC by way of a relay. Another – the chosen one – was to send the ringing signal as a tone which could go via the selector network. This implied the delivery of special telephone sets with a tone ringer or rather an amplifier for the tone signal from the exchange, able to operate with so little current from the line that it was still seen as being on hook. This was different from tone ringers as they are found today in telephone sets, they are rather tone generators supplied by the AC ringing.

Only for lines to hunting groups we had to deliver AC ringing, so we did not avoid providing a special circuit between LC and line which could receive the tone signal and in step with this signal connect AC ringing to the line.

This method implied that suddenly other types of subscriber installations also had to be adapted to ETS 3. A very common installation is the use of parallel sets (which is forbidden due to secrecy considerations in e.g. Sweden and Germany). But when one used a set the tone ringer in the other one squeaked and it was in fact possible to hear what was said. The filters for the tone were of course very cheap and not very selective.

JTAS accepted that parallel sets could be removed in the 1000-group in Århus which ETS 3 should serve. But they could not accept removal of extra bells, connected in parallel over the line. So Philips had to develop an extra bell which in itself was easy enough, it was just a tone ringer in a separate box. But the squeaking had to be removed, too. I came on the solution: The tone ringer should only work when the telephone set is on hook and there is a large voltage between the wires of the subscriber pair. As soon as the telephone set answers by going off hook (and making a loop through the microphone between the wires) the voltage between the wires drops. This could be used in the extra ringer, a Zener diode in series with the ringer ensured that the tone ringer could only be active in the on hook state.

Another circuit we had to deliver was a subscriber meter for subscribers who wanted to keep an eye on their costs, e.g. for telephones on loan in a restaurant. At that time the signal to a subscriber meter was a rather high 50 Hz AC voltage, sent in parallel on both wires and with earth as a return circuit (an unbalanced signal). The speech circuit in the telephone set was only sensitive to differences in voltage between the wires (a balanced signal) and should therefore ignore the metering pulses.

ETS 3 could not send such an unbalanced signal through the LC transformer, only balanced signals were possible. Thus, a high-frequency tone was sent to subscribers with a meter which we also provided. It contained a filter so the tone would not be passed on to the telephone set.

Today 50 Hz metering is on its way out to be replaced by the system ETS 3 was the first to introduce. But it is a slow process like so much in telephony. Philips’ PABXes EBX 8000 and 800 could e.g. only work with 50 Hz metering as KTAS and FkT would not invest in new circuits when the possibility existed in the early 1980es.

When we had to deliver telephone sets we could as well deliver modern sets with push-buttons, which gave a tone signal that could go through the selector network. There was as yet no standardization in this field, the first proposal for the system used universally today came from Bell in the USA in 1962. Thus we could choose freely and choose for economical reasons a system with only one tone generator in the set. The push-button selected which tone to be sent. This signal could of course easily be imitated by whistling or speaking into the microphone. So we choose to block the microphone and revert to the on hook state whenever a push-button was pressed. The exchange would know in the relevant tone receivers that when there was a digit signal simultaneously with an on hook state the subscriber had not really gone on hook. But if you were in the middle of a conversation and pressed a push-button there were no tone receiver connected and the exchange could only perceive it as the end of the call.

An item which even in the 1990es could inflame people was the placing of the push-buttons. In 1991 this topic came up again in Denmark and I wrote the following in the engineers’ magazine “Ingeniøren”:

The telephone keys, shall 1 be on top or below?

“The articles in “Ingeniøren” no. 20 and 25, 1991, on the placing of the keys on the telephone keypad makes me join the debate after having followed the ups and downs of the digit 1 over 30 years.

Whether there was a connection between Strowger’s dial and the placement of the keys I do not know. The tone system used today, a low- and a high-pitched tone for every digit and choice of tones with a minimum of harmonic content so they are difficult to simulate by whistling in the microphone, was proposed by Bell in the USA early in the 1960es. Already then the placement of the keys was also suggested and it was in the end of the 1960es standardized in an international recommendation called CCITT Q.23. Reasons for the placing with 1 top left was that terminals on IBM computers at that time had 1 top left, only few people used desk calculators with 1 below left, and for everybody else the natural sequence was to have 1 top left.

The system is based on having for each row of the keypad one of the low tones and for each column one of the high. 1 has the lowest tone in either group, 697 and 1209 Hz, etc. Only two tone generators are necessary, tuned as required by the relevant row and column. If each key had its own two generators one was of course free to place the keys as one wanted, but it would require 24 tone generators and be too expensive.

But already in the 1960es a keypad with 7 top left was used in Denmark. In 1960 an agreement was made between on one side KTAS, JTAS and the Dutch PTT and on the other side Philips concerning the delivery of fully electronic test exchanges with program control and selectors with thyristor contacts to the public networks in Copenhagen, Århus and Utrecht. Philips should i.a. supply special telephone sets adapted to the test exchanges. It was keypad sets and KTAS wanted 1 below left, JTAS did not care and PTT wanted 1 top left. In any case the telephone sets had to be different between Holland and Denmark as the Dutch sets should have only digits on the keys (Holland was fully automatic since 1962), the Danish sets should have digits and letters due to the Copenhagen demi-automatic exchanges called by the two first letters of their name. The tone system was a special one, it was before Bell’s proposal, with only one tone generator and therefore only one tone for each digit. Simulation of digits by whistling into the microphone was prevented by almost cutting the current when a key was pressed. The exchange knew that on hook together with a tone meant a digit, so it worked fine and blocked effectively for simulations.

I worked in the development at Philips and suggested that as it was not a standardized tone system it did not matter that a press on the top left key always gave the same tone, even if it meant 7 in Denmark and 1 in Holland. On the telephone sets the top row was interchanged with the third row and in the exchange it was only one cable form between tone receivers and digit registers which had to be different in the two countries. This was approved and both KTAS and PTT were accommodated. Later the exchange in Copenhagen was cancelled after proposal from Philips, while the two others were in operation from 1967 to 1973.

The next phase is early in the 1970es where the Danish telephone administrations – as the first ones in the World – would introduce keypad telephones as the standard telephone which was supplied with every new subscription then. In the meanwhile pocket calculators had proliferated with a keypad inherited from the mechanical calculators. In these 7, 8 and 9 had to be on top so they could have a longer movement when pressed than 1, 2 and 3. This caused Asger Kjerbye-Nielsen, then head of the research laboratory of the administrations, to propose that 1 should also be below on the telephone keypad (but naturally still consist of 697 and 1209 Hz) in spite of the international standardization. His view won and the Danish standard telephone sets 76E (Comet) and F78 (danMark) got a calculator keypad.

This applied to standard telephone sets. In special sets and operator sets for PABXes 1 remained top left. It would be too expensive to adapt them to special Danish wishes. So except for the Minimat and OCS built at Kirk in Horsens where the operator set is an enlarged version of the Comet set from the same factory, users of special sets and operator sets under PABXes like the Swedish ASB and MD 110 at KTAS, the Canadian SL 1 at JTAS, the Belgian OMNI at FkT and the Dutch EBX, TBX and SOPHO S at KTAS (and EBX at FkT) had to get used to the international telephone keypad.

And now one of the consequences of the liberalization is that if you do not target your product on a small segment of the market – such as is generally done by B&O with their radios and TV sets – you can not afford making a set for the Danish market which deviates from the international standard.

So the only way out for those who insist that the keypad on telephone set and calculator shall be identical is for the time being to buy a Beocom telephone set.”

When this article had been published P. V. Arlev from JTAS phoned me. He and Philip Hansen (who died much too early in the end of the 1970es) were the ETS 3 experts of JTAS and spent a winter in Hilversum to learn about the exchange. More on that later! Arlev was now on pension and would comment a few points in the article.

“JTAS did not care” I had written. It was the head of the laboratory, A. Ortvad, who did not care whether 1 was on top or below. The managing director, Draminsky, cared very much but was not asked before the placing of the keys could not be changed any more. But, said Arlev, he insisted that he would not have a set with 1 below on his desk, so Arlev and Philip Hansen changed an ETS 3 set so it had 1 on top but the frequencies followed suit. Arlev had also had such a set.

Server circuits and their control

Enough about the subscriber side of ETS 3. Now the other side with the server or traffic circuits. There were circuits for internal traffic, VS for Verbindings Schakeling, For outgoing traffic, UO for Uitgaande Overdrager, for incoming traffic, IO for Inkomende Overdrager, for digit receiving, CO for Cijfer Ontvanger, for digit sending, CS for Cijfer Sender. All of it controlled by a server supervisor, VB for Verbindings Bewaker. In addition there was a digit memory, CG for Cijfer Geheugen, for digits to the LME exchanges.

All calls to subscribers outside ETS 3 went to a group selector in the local LME exchange. CG had the task to send the digits needed by the LME exchange to it. The signalling was such that the LME exchange reported back after each digit what it wanted next. The next digit or a repetition of the same one.

There were two types of CO, one for digits from the ETS 3 subscribers (local CO), one for digits from the LME exchange (LME CO). When a subscriber started a call he was first connected to a local CO and after dial tone all digits were sent to it. If the called number was to another ETS 3 subscriber the call was transferred to the incoming side of a VS and its outgoing side was connected to the called number and ringing signal was sent. If the called number was outside ETS 3 the VB passed all digits to the CG. At a certain moment a CS and a UO were called in and the digits were sent via these to the LME exchange. When all digits were sent the connection from the LC to the local CO was switched off and a connection between LC and UO was made and the conversation could begin.

An incoming call arrived at an IO and it called an LME CO. The VB received the digits and would cooperate with the other parts of ETS 3 to connect the IO with the called number.

The local COs, VSes, UOs and IOs were directly connected to the last stage of the selector network. Each VS even with two connections, for the calling and the called side. Each had also a receiver for the 20 kHz off hook signal from the LC (again the VS had two). The UOs and IOs contained a transformer to translate between the unbalanced transmission in the selector network and the balanced transmission to the LME exchange. In addition it separated the DC conditions on the network and exchange sides.

The COs (both local and LME) received autonomously complete digits and delivered them to the VB for analysis. That is: the logic in the local COs could count dial pulses and interdigital pauses and in the LME COs combine the signals from the LME exchange to complete digits. This implied that the VB needed not scan the server circuits as often as if the VB had to scan fast enough to detect every dial pulse. But keypad signals were anyhow quite fast, a new digit might come every 80 ms.

In the direct connections to the network there was a DC generator, which supplied the holding current to the speech path through the network. It was in principle a constant current generator as it should not attenuate the speech signal. During marking there was a high voltage and a very little current, when the last stage had been switched through to the LC and a larger current could flow through the transformer the voltage dropped. In the start we had a problem: The generator actually dropped the current to zero so the speech path was interrupted again!

Blom, who also had made the generator, had to go back to the drawing board and redesigned the generator so it instead gave a constant high voltage whenever the current was below a certain level. At that level it worked as a constant current generator.

The VB was constructed by Jongkind. He later moved to Philips Eindhoven to work with their internal telephone network. They liked to call it “the World’s largest” with about 30,000 extensions in the factory- and office-buildings in this hometown of Philips.

Those parts of the UO, IO, LME CO and CG which faced the LME exchange were in my charge. Schmitz found that it would be a very difficult job because it meant cooperation with another telephone system. The mutual signalling was a problem when one delved into details like pulse times and pulse shapes and their tolerances. But I had first class helpers. Jos Hruschka for the circuitry in the UO, IO and CO and Dick Schuitemaker for the CG. Another help was strangely enough that I would not let Hruschka construct anything before we had a complete description of the signalling. It was the so-called LME DC signalling, where e.g. digits were sent as a series of +/-, /+ pulses.

The main problem was that the Danish administrations had made the job as easy for themselves as possible and had only for every order for a new exchange from LME required that it should cooperate with the existing exchanges. LME had delivered all the other exchanges and could live with that and only tell as much in general terms about their signalling system as they were forced to. And that was far from enough for a new supplier who should cooperate with it! So both KTAS and JTAS were very grateful for the report we made on their signalling system.

We received of course the information the administrations already had and then I started harassing them on the details necessary for us to make our circuitry. During the summer of 1962 I was in Copenhagen with a test box to measure if the information was OK. And then the construction proper started, including the differences between Århus and Copenhagen. When I moved to Denmark in the autumn of 1963 I was replaced by one of the most clever developers in the laboratory, M. Koeman. And in the summer of 1964 the cabinets with UO, IO, LME CO and CG were in the two cities, the three Dutchmen were 4 weeks in Copenhagen and 4 weeks in Århus to test everything (according to the plans made) and it was OK. So all the circuits for the cooperation with the LME exchanges just stood waiting for the rest of ETS 3 until all was delivered and tested in the middle of 1967, 3 years later, and the exchange became operational.

I have met the three also after ETS 3 became operational. Koeman was in Denmark several times to discuss possible deliveries of our next system, PRX. But in 1974 he was going back to Holland after a business trip to Brazil when the Varig-plane in which he was a passenger crashed near Paris. All died.

I only met Schuitemaker a few times. He and Hruschka left Philips when the activities in public telephony were sold to AT&T in the middle of the 1980es. I met Hruschka several times at international conferences, ICC and ISS. It fitted also well that I was for other reasons in Holland in 1975 when he was married and I could come to his reception with a gift from Philip Hansen from JTAS and myself. Again in 1982 as I was in Holland to assist in making a development report on what was later called SOPHO S it coincided with his 25 years jubilee in Philips. On my 50 years birthday.

There were differences between the signalling in Århus and Copenhagen. Here I shall only mention one, viz. double proceed signal in Copenhagen. After every digit in the forward direction an exchange waited for a signal in the backward direction which told whether the next digit should be sent or if the same digit should be repeated. This return signal came from the digit receiver itself and there were only few of these. It was therefore important that the digit receiver was only called in when all the digits it should have were ready in the digit sender. In Århus this was realised by letting the sender wait with starting the build-up of a connection until all 6 digits in the local subscriber numbers were available. In Copenhagen KTAS wanted to reduce the post-dialling delay (between the dialling of the last digit and the start of ringing or busy tone) by already starting the build-up of the connection when the 5th digit was received in the sender. But the last digit receiver should of course not be called in before the 6th digit had been dialled.

This was realised with a double proceed signal. There was not immediate access to the last receiver but only to a circuit before it. That circuit gave a polarity on the incoming line equal to a proceed signal (like the proceed sent by the digit receiver of the previous stage). When the sender had the 6th digit ready it connected a signal receiver (a relay coil). The incoming circuit perceived the current in the line and called the digit receiver. It then connected a relay coil for digit reception and the stop for current was sensed by the digit sender which connected polarity for digit sending. Thus the digit sender should see two proceed signals before sending the three last digits required by the last stage (which covered the build-up of the connection in the 1000-group of subscribers).

Considering that our subscribers had keypads they could dial faster than others. Their post-dialling delay would be too long if we waited with the start of build-up until the 5th digit was received. So we started the build-up in Copenhagen when we had 3 digits available, the sufficient number for all stages except the last.

It was considered one of the major tasks in the development to make this adaptation to LME’s DC signalling, but the method chosen, to first collect all information and then develop, resulted in that this was the only part of the development of ETS 3 which went according to schedule. Of course I could easier resist demands to quickly design circuits so the factory could proceed producing them because I was not paid directly by Philips in Hilversum. I got my salary paid in Denmark so there were no holes in e.g. pension payments.

But do not believe that it was just like that to develop the adaptation. To illustrate this I shall quote from LME’s booklet “A switch in time” on their development of the AXE system. It concerns the change of a transit exchange in Ålborg from AKE to AXE and says: “At a special visit in Stockholm the new system was discussed and Kaj Juul-Pedersen presented a particular solution for exploiting a digital switch to handle the local network. (He admits he later regretted this, since the digital handling of the direct current signalling system proved more challenging in software than anticipated).”

Another couple of special circuits. Release of a connection occurred by sending forward an AC voltage of about 100 Volts. In the LME exchanges it ignited a neon lamp and the current through it operated a relay. We did not have a neon lamp with the required specification and we disliked in general to use this kind of component. In stead we found a 56 Volts Zener diode which we put in series with our relay inside a rectifier bridge. Such a Zener diode was quite a speciality in 1962, only General Electric and Intermetall could provide one. We choose the latter. Our relay for reception of release signal was a large reed relay from Standard Electric, 8 cm by 1 cm by 1 cm!

Digit reception occurred in the LME exchanges with a polarized relay which operated a chain of normal telephone relays. A polarized relay is very sensitive and reacts very fast on small currents in the line. It was used for reception of telegraphy signals. There can be short disturbances (transients) on a line. The polarized relay would react on these but they would be removed by the slow operation of the telephone relays in the counting chain.

We did not like this principle, nor did we believe that we could make the two types of relays cooperate properly. It was too marginal whereas Philips’ principle rather was that everything should work even under the worst of circumstances, if only every component was within its specification.

Thus I constructed a digit receiver according to quite another principle. It used a couple of the large reed relays, which were rather insensitive, as input (one for either polarity). In the worst case, i.e. on the longest lines, one of these would only be operated for about 2 ms during each pulse and that was too short to operate our telephone relays in our counting chain behind the reed relay. But in any case we had about 10 ms from the operation of one reed relay to the operation of the other for the next pulse. We could therefore cope with the problem by letting each reed relay drive a monostable multivibrator which ensured a pulse of at least 8 ms to the relay chain. And it worked. When the circuit was made according to my design there was only added one component and that was only for reasons of the measurement. It looked confusing on an oscilloscope as one of the interesting wires for a short moment, while a telephone relay changed over, was not connected to any voltage. It looked as if there was a short, wrong signal. It was remedied easily by tying the wire to ground through a high-ohmic resistor.

Coordination of the whole exchange

Enough about the circuits facing the LME exchanges. There are still two control modules left which kept the whole exchange together, the program store, PG for Programma Geheugen, constructed by H. Mol, and the recording module, RG for Registreer Geheugen, constructed by Baas.

PG was the first module in Philips’ telecommunication equipment which operated with a stored program. Today we would probably call it firmware, for the program was stored by having the wires for setting and resetting (reading) the ferrite cores woven through them. Every word in the store was selected by a horizontal and a vertical address. The word consisted of three numbers, one for the module which should have the order (e.g. AG), one for the order itself (e.g. test called subscriber) and one for the horizontal address of the next order in the PG. The answer from the module to which the order was sent was again a number for the vertical address of the next order (different for e.g. a free and a busy subscriber) and thus the next program step was decided.

In all other modules the logic (the program) was realized by connections between core amplifiers. The method in the PG was quite novel at that time. Sure there were data in e.g. the CG on how many digits should be dialled for each combination of the two first digits etc. (Copenhagen had a mixture of fully automatic, 6 digit exchanges and half automatic, 2 digit exchanges) woven into ferrite cores in the same way, and the AG had a proper data store with a uniform wiring and setting of ferrite cores controlled by a program, but only the PG had the logic as a stored program.

The RG was the interface to the teleprinter terminals which could change subscriber characteristics, read metering information and read information in case of faults in the exchange.

AG, VB, CG and PG were duplicated due to reliability reasons. We had chosen “cold stand-by”, i.e. the chain of modules not actually controlling the exchange were idle (without clock pulses). In case of a fault which caused the stand-by chain to become active all existing calls could remain active, because it was tested directly in the selector network whether there was a free path for every new call. Thus there was no risk that a new call would be switched into an existing one. But it meant that the “new” VB did not know who had called so metering pulses could not be put on the right counter any more for calls existing during a change over. That was a small problem as such a spontaneous change over almost never occurred. There was a routine change over every night so a chain did not be too long without supervision, but that occurred of course at a time when there was no traffic whatsoever in the exchange.

Another consequence of the cold stand-by was that the RG when it read metering information or changed subscriber characteristics had to awaken the stand-by chain and work with it as well. For metering information the RG had to add the figures from the two AGs to get the correct number of metering pulses.

Mol had described the program of the PG exclusively in lists, which for every address in the PG (each combination of vertical and horizontal address) showed the three numbers for module, command and next horizontal address. Before the PG should be produced it was necessary to check the program, Schmitz asked me to do it and I soon went astray in the lists. Luckily I had read about flow charts and used them myself in my work on the DC signalling. So I translated the lists to flow charts where the program was far easier to oversee and checked it. It may sound improbable but there were no faults in the program! However I could propose an improvement: Two answers from two different modules gave always the same result. I proposed that they should point to the same vertical address and this was approved. At the time there was no special reason to make a vertical address free in this way, but later on there was a need for yet another answer from a module and then this spare address was welcome!

Mol was from the HTS engineering school and was very angry because MSEEs automatically came into a salary class which it was difficult for him to enter. Schmitz was also from the HTS school but had the qualifications to become head of a group. Mol had the technical qualifications as an expert and I understood his anger over his lower salary although he performed better than many an MSEE. He and his wife and their 6 children also lived quite close to us in Hilversum and we met also outside the laboratory. We bought each our first car almost simultaneously and it was a treat for his family when they went driving. With that size of family (and his salary) they had of course chosen the minibus version of Fiat 600.

Mol had lived in Hilversum all his life and had therefore also experienced the “Hunger Winter” from 1944 to 1945. He and other children went in their worn-out shoes (no new ones since 1940) to the villages along the Ijsselmeer, Bunschoten and Spakenburg, 10 to 15 km from Hilversum to beg for food.

Baas developed the RG and had to follow up on what others had not thought about. And what he had also not thought about. Again we had a teleprinter as input and output medium and nobody had speculated over the fact that such a device can not stand to be running all the time. It must have a timer to stop it after a couple of minutes of no activity. And when it starts again one must wait a few seconds before it is running at speed and can detect the data correctly. This was introduced underway. Baas was later involved in the development of Philips’ teleprinter (PACT) in Stockholm and worked for several years in Sweden.

Concurrent engineering

As said there was a pressure for quickly feeding the factory drawings so it could begin producing units for ETS 3. The idea of “concurrent engineering” which seems so new was already our practice then.

The heart and soul behind it was Reydon from the factory office for production preparation. He was often in the laboratory in order to translate our drawings to what was needed in the factory.

Rain torrents and placing on wooden bars

In 1962 we were so far that ETS 3 could begin to be installed in the laboratory. Not the whole of ETS 3 but the modules should as they became ready be tested alone and in cooperation with the other already available modules.

A day with nice dry weather just to a quarter past 5 (we worked from 8 a.m. to 5.30 p.m. with an hour free for lunch) the clouds gathered suddenly and rain began to fall in torrents. It only lasted a quarter of an hour so we could go home at the normal time, but during that quarter it had rained so much that neither the earth or the sewers could cope with it. Hilversum is a little lower than its surroundings (maybe one metre, Holland is flat) and as I went home on bike I saw in the middle of the town how water came up from the sewers. The road under the railway was completely flooded (this happened about once a year). I came home and found that luckily my wife had also not been out in the worst rain.

But there was trouble in the laboratory. It was placed in an old factory hall with its floor at earth level, so rain poured into the hall. There were several telegraphy exchanges in their development phase. This was a major product at that time, especially to airlines (SITA, Society for International Telecommunications for Airlines) and air traffic authorities. Philips had also to United Airlines in the USA delivered a transmission system for ticket booking. From the terminals on the main connections towards the East and West Coasts the answer to a request or a booking had to be less than one second including the time used in the main computer. It worked!

All telegraphy exchanges had their power supplies in the bottom of the cabinets. The rain water seeped in and spoiled them. It gave a serious break in the development.

Of course Schmitz would not risk this for ETS 3. So except that the risk for ETS 3 was minor (no electronic part was closer than 10 cm from the floor) he got hold of some wooden bars of about 10 cm square on which ETS 3 was mounted.

Guards at the gates, de Kroes

The working time was as said 8 a.m. to 5.30 p.m. with one hour for lunch. The latter was fine, otherwise the days might be long for my wife although she got to know the wives of some of my colleagues and they visited each other. I biked home in 20 minutes, had 20 minutes for lunch and biked back in another 20 minutes. Good for my health!

Philips had their own guards at the gates. Clad in black uniforms they received us in the morning and watched that only employees came in. It was before ID-cards with magnetic stripes became general, they relied very much on knowing the faces.

Sometimes they closed the gates at 8 a.m. sharp except for a narrow passage and they asked everybody coming later for their salary-number. For my part I could say that I had no number. I got my salary in Copenhagen. This was the good old days before immediate taxation, so I paid no tax there. But had of course to state my income to the Dutch authorities and pay tax in Hilversum.

In the lab we talked about what became of the lists with salary-numbers? Nobody ever saw any effect of them. We agreed that they probably went to the head of the exchange lab, J. L. de Kroes (later professor at the technical university in Delft). He saw every time his own name and salary-number on the list and threw it away!

Interruptions in the work

There were other things which could interrupt our work in the lab. Here only a couple of very special events:

Beside our lab for development of exchanges (public, private and for telegraphy) a new building was erected for the development of transmission systems, building BD. It was much prettier than our building, which dated back to the 1920es (where Philips had both studios and senders for broadcast in the buildings). It was also much higher, 5 floors and a “wind tunnel” on the roof for the air-conditioning. The old houses had two floors along the sides and a free room in the full height in the middle, for factory purposes.

BD was built by help of a large crane running on rails between our building and the new one. And at last BD was ready and the crane should be dismantled. That day we did not work much in the lab, it was too fascinating to see the crane slowly laid down and then, after the ballast was shovelled out see the long apparatus be rolled out from the factory premises. Turning corners where there was no room for it. If it still exists there are traces on some of the bricks on the corner of building AV, where predevelopment took place.

Another day without much work in the lab was when the rails between the two buildings were gone and the place should be paved. It was done by a true specialist. How he could even out the gravel, plane it and compress it before he laid one stone after the other (hard-burned bricklike stones on their edge as generally used in Holland). Not a stone was relaid, everything was correct at once. We all hang in the windows and admired the work, comparing it with our own efforts when we should lay stones on a few square-meters. And thought about how short a time it normally took before our stones were uneven…

Buchner’s demoralizing effect

Second in command in the switching lab was R. B. Buchner. He spent much of the time thinking. Leaning back in his chair with the feet on his desk. At first he had an office at the side where building BD was erected. And then he moved around the corner. We agreed that the reason had to be that it would be too demoralizing for the developers in the new building to be able to look all day at the seemingly apathetic Buchner. He moved to an office facing the social centre with personnel office etc. We quite agreed that there he could not demoralize anybody. And not because they worked so hard that they never looked through the windows!

Dooren and van Duuren

For some time I shared office with Dooren. He had grown up in Arnhem and experienced September 19th, 1944, there. The same day as the police in Denmark was arrested by the Nazis and sent to concentration camps the Allies tried to seize the bridges over the great rivers (“One bridge too far”) by a major air landing operation near Nijmegen and Arnhem. The bridges by Nijmegen were seized, not the bridge by Arnhem. The Nazis were lucky to have a tank group nearby. The allied forces were defeated, the bridge was blown up. Even in 1949 as I was for the first time in Holland the big road-bridge lay with one end in the water.

After the Nazis had won they would punish the inhabitants of Arnhem for their help to the enemy and declared the whole town as booty. All inhabitants had to leave the town within a few hours, first from the centre, then from the suburbs, each carrying only a small bundle of clothes or the like. It was not the victorious army’s sake where they could find shelter. The troops could then in all ease empty the houses of furniture and other valuables (and spoil the rest). A terrible experience for a boy like Dooren!

A somewhat different remembrance from van Duuren, who was not in our group but in the development of telegraphy exchanges. He told about the great floods in 1953 while he was studying. He and several others worked on a dike in Zeeland. It stretched into infinity on both sides. They placed sandbags along one side of the dike. On that side there was water, already higher than the crest of the dike but held back by the sandbags. And that water was still rising. On the other side of the dike, deep down, was the rest of Zeeland. If the water had broken through nothing could have saved the people, the animals and the farms down there. So the team of students built the wall of sandbags higher and higher until the water finally sank.

This tale fitted with what Jan van Dorsten had told me: He and other students from Leiden were also called in. Jan worked in Does limiting the water damage and did not sleep in several days.

If you meet with 5 Dutchmen you can be sure they belong to 5 different churches and 5 different political parties. But when the water threatens, the big floods of 1953 and the plan for Deltawerken afterwards showed that the Dutchmen can join their forces.

Telex on radio (TOR)

The father of van Duuren was employed in the Dutch PTT and had invented a method for safe telex transmission via radio connections. Their problem is that the connection is not reliable, there is fading and other disturbances making the connection fail now and then. Not completely, but there are holes in the transmission.

The older van Duuren had from the 32 different telex characters (with 5 bit each) made a new code with 35 different characters, each character having 7 elements and with exactly 3 of these being 1-elements. This code was sent and if the receiver did not receive 3 1-elements in a character it asked for a repetition of the character. The 3 extra characters were used respectively as a request for repetition and as idle characters when there were no messages, so sender and receiver were held synchronous.

Philips had a few years before received a large order for telex transmission in Argentine. With the technology of the time van Duuren’s method was too expensive although it was the standardized method and had to be used on international connections. But Philips invented their own method for use on the national connections. I can not remember how this code worked, I think it was based on an extra parity bit to the 5 data bit in each character and (like the van Duuren code) on the repetition of characters which did not arrive correctly (i.c. with the right polarity).

After I was back in Denmark this method came up as a possibility for telex transmission in Greenland. Tele Greenland would like to connect all the small outposts along the Westcoast with troposcatter systems, i.e. radio links without line of sight. In stead a high-power signal is sent into the atmosphere over the horizon. There the signal is scattered by irregularities in the atmosphere and a small part of the signal could reach a sensitive receiver well beyond the horizon. This system was invented during the war (1940 to 1945) and was used after the war between e.g. Western Germany and Berlin, so there was no dependence on wires or radio towers on East German ground.

From Tele Greenland mr. Pingel Rasmussen was an expert with all calculations of the possibilities. Distances and sending power were realistic but with this form of scattering there is a very heavy fading with a certain distribution, so-called Raleigh fading. This lead to long discussions of whether it was the van Duuren code or Philips’ own code which would perform best with this type of fading. These discussions took mainly place between Pingel Rasmussen and Miss Jung from Philips Hilversum. She lived for the mathematics and we others could only sit quiet by and listen when those two discussed.

It was possible to make scenarios (that designation was not invented at that time) where one type of code was the best and scenarios where more came through with the other. A choice had to be made. I do not remember the result, but I doubt that Tele Greenland after all choose other than the van Duuren method for their first radio link along the Westcoast.

Engineer meetings in Eindhoven

The engineers at Philips were members of a “Society for Young Academicians”, Geselschap voor Jonge Academici, with most members in Eindhoven. They issued i.a. a yearbook making fun of many items in the company. E.g. the difference in dress between people in the labs (unwashed sweater and sandals) and sales engineers (suit and a thin attaché case, the less it could hold, the higher your position). Or the witchcraft in the deep cellars: how to make coffee without coffee for our consumption while at work.

The society met also regularly and I particularly remember one to which we were a few who had driven down from Hilversum to participate. It was a meeting with a question session afterwards with the president of the company, Frits Philips, son of Anton Philips who with his brother Gerard had started the company in 1891. Frits Philips went over the annual accounts which had just been published and commented them. And then there were questions.

One of these was why the turn-over in each industrial group was not mentioned? It was shown how the turn-over had developed over the last ten years for each group and the total turn-over for the company over the last ten years was also shown. Thus, competitors could just solve ten equations with ten variables to find it out? Frits Philips answered that competitors were welcome to do so, but the company would not help them. Since then all these figures have become part of the accounts, probably mostly due to requirements on the New York Stock Exchange where Philips shares are traded.

Another question was whether it did not damage our image as a professional supplier that we were so strong in the consumer field? In comparison with e.g. Siemens who almost exclusively worked with professional equipment like telephone exchanges, X-ray equipment, power stations etc.? To this Frits Philips answered that he could promise us that all the companies one could think about were rather very envious at Philips for their strong presence in the consumer field. For one thing the professional customers met our name all the time, in and out of their offices, but it was a good basis for the company that there was this large turn-over in small orders, while orders in the professional field most often came as a big lump so it was close to a catastrophe if the efforts to get in did not result in an order.

Money machines

Another trip, either arranged by the Engineers’ Society or the club in Eindhoven was a trip to Antwerp to visit ITT’s telephone factory BTMC or Bell Telephone Manufacturing Company.

What made most impression on me in their production was to see machines which produced one rotating selector after the other of the model used in the Copenhagen demi-automatic exchanges since the 1930es. This must have been quite a money machine for the development of those selectors must have been written off long ago. Nice for a factory to have that kind of products!

Philips Hilversum had also a product with similar properties as a money machine: Loading coils or Pupin coils as they are called in Europe. Already in the middle of the 1800es the formula for attenuation along a transmission line had been calculated. And found that one could obtain a lower attenuation by increasing the self-induction in the line! It sounds crazy, the self-induction blocks for AC currents and then such an inductance could be used to reduce the attenuation of AC currents (up to a certain frequency)! It is due to the interplay with the capacitance between the two wires of the line that such a surprising result can be obtained.

In Denmark Krarup constructed a cable exploiting this effect. He wound a thin iron thread around each copper wire. This was, however, an expensive solution and the really widespread method was Pupin’s, where the self-induction was lumped in coils for each kilometre or 1.5 kilometre.

Philips had on the basis of their ferrite materials made loading coils and it was for many years a nice product without large problems between order and delivery. This was the time when all telephone connections within a town were in separate wire pairs and where it was therefore important to have a small attenuation between the exchanges. Then it did not pay to invest in transmission systems for many calls on each pair before the exchange distance was more than 20 kilometres.

Military service?

A short time after we moved to Holland I got a letter from the Dutch armed forces: I would not, considering my foreign nationality, be drafted for military service.

Nice to know, but it was definitely not our reason to move to Holland, that I should become a soldier during the two years our stay was planned to last. In addition I found I had done enough for NATO: First 5½ years in the Home Guard while I studied, then 2 years in the Navy, the latter spent on several patrols in the first line in the Baltic Sea. So I would have had something to say if the Dutch authorities had written me differently!

Jan becomes a doctor

In the spring of 1962, a couple of months after our first child, Marianne, was born, Jan should defend his doctor’s thesis at the university in Leiden.

It fitted with a visit by my mother to see her latest grandchild, and we were invited to Leiden to be present at the celebrations.

I was even invited to be present at the defence itself in the very small Senate Chamber at the university. There the strict judges were sitting with the few guests. And the defensor was led in by a couple of his friends from the university and placed in front of his judges. And then the questions and answers began.

The dissertation “Poets, Patrons and Professors” treated the first years of the university and its affinity to Elisabethan England in those years. This was the time when Holland was making itself free from the Spanish rule. Leiden had been besieged by the Spanish for a long time but was liberated (they still celebrate “Leidens onzet”, liberation, on October 3rd every year). The Dutch sought help where they could get it and found it to a large extent in England, who helped not only with the war but also with the foundation of the first university. Later Jan became a specialist in Sir Philip Sidney, one of the many polyglots the former times had, who worked at the university and as a warrior. He was deadly wounded in the battle at Zutphen in 1586.

Well, Jan obviously did well, for he was named a doctor. And in the evening there was a large feast for him in which also we two Danes participated.

“Shuffling Swenn”

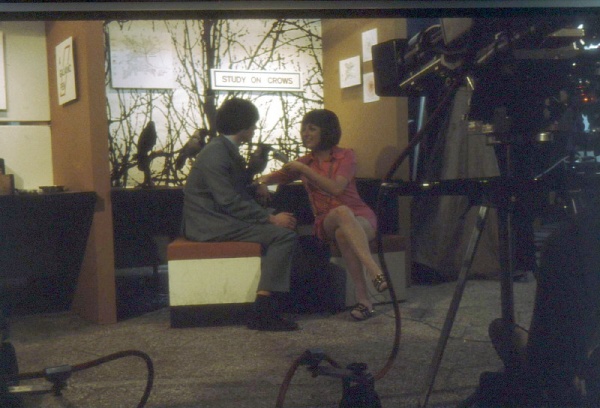

P. V. Arlev and Philip Hansen from JTAS and E. W. Ihle from KTAS were a couple of months in the end of 1962 in Hilversum to learn more about ETS 3. I think Philips was pressed to this by the administrations, for it was far too early to be very specific about the system. We had to cover up as best as possible.

As a Dane this became my task. It was with great reluctance I visited them in their office because they had every day new questions which neither I nor others in the lab could answer yet. But the three of them expected answers here and now – fair enough, for the delivery of ETS 3 was (we all believed) just two years ahead.

So it was with dragging steps I went to the other Danes. In addition I had some days a couple of shoes on which did not fit too well. So Hruschka soon named me “Shuffling Swenn”!

The people from Jutland lived in Loosdrecht, in a couple of holiday flats at one of the many marinas with places for and renting of boats (which was of course not active in November), while Ihle lived in a hotel in Hilversum. Years later the owner of the marina, Boshuis, was angry at Ihle, who he believed had also rented a flat. Arlev should have told him that Ihle would not come and always stated that he had indeed done so.

“C’est l’habitude”

I was alone in Hilversum while the three Danes were there. Our first child, a girl, was as said born in March 1962 and my wife did not like the idea of living through the winter in Holland with a small child. All Dutch children had constantly a cold and got their tonsils cut out, for the houses did not live up to Danish standards for insulation and heating. As examples our flat had iron window frames and the windows had a single layer of glass. The heating was an oil stove which smelled more than it heated. The oil came from a 200 litres tank on our balcony which had to be filled up every week. So she went with our daughter to Denmark and they stayed with her parents from early November to early March.