Category:Manufacturing & production: Difference between revisions

From ETHW

No edit summary |

m (Text replace - "[[Category:Power,_energy_&_industry_application" to "[[Category:Power,_energy_&_industry_applications") |

||

| Line 26: | Line 26: | ||

*'''[[:Category:Transfer molding|Transfer molding]]''' - an automated process that uses pistons to squirt the material into the cavity through small holes and then pressure and heat to cure the material | *'''[[:Category:Transfer molding|Transfer molding]]''' - an automated process that uses pistons to squirt the material into the cavity through small holes and then pressure and heat to cure the material | ||

[[Category:Power,_energy_& | [[Category:Power,_energy_&_industry_applications|{{PAGENAME}}]] | ||

Revision as of 13:37, 13 November 2013

Various issues dealing with the manufacture and production of electronics

Subcategories

- Ball milling - the use of a cylindrical device containing grinding mediums such as ceramic balls to grind material to a find powder

- Compression molding - a molding method in which the molding material is placed in an open, heated cavity and heat and pressure are applied until the material is cured

- Embossing - the process of producing raised or sunken designs in sheet metal, paper, or other materials

- Fabrication - the building of metal structures by cutting, bending, and assembling

- Group technology - or GT, a manufacturing process in which the parts having similarities are grouped together to ensure a higher level of integration

- Injection molding - a manufacturing process in which thermoplastic materials are injected into a mold cavity and hardened

- Manufacturing products & systems - the products and system that make up a manufacturing process

- Materials processing - the transformation of input elements into useful products

- Mechanical products - products that can manipulate materials

- Production control - activities involved in handling materials and assemblies from their raw to finished stages

- Production engineering - a combination of manufacturing technology with management science to insure optimal manufacturing capability

- Production equipment - the mechanical equipment used to facilitate production

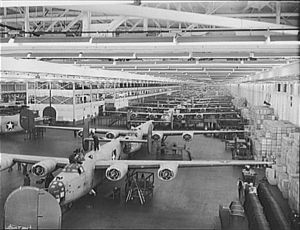

- Production facilities - the structure and infrastructure used to facilitate the manufacture of products

- Production management - the management of the entirety of the production process

- Production materials - the material inputs of a production process

- Production systems - the comprehensive system of production

- Shafts - vertical passageways that transport people or material

- Tolerance analysis - the study of accumulated variation in mechanical parts and assemblies

- Transfer molding - an automated process that uses pistons to squirt the material into the cavity through small holes and then pressure and heat to cure the material

Subcategories

This category has the following 3 subcategories, out of 3 total.

Pages in category "Manufacturing & production"

The following 23 pages are in this category, out of 23 total.