Archives:Transformers at Pittsfield, part 1

Preface

Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock

In 1886, William Stanley first successfully demon¬strated the use of the transformer in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts.

In 1986, the General Electric Company announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before.

The technology associated with the design and manu¬facture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a for¬eign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands.

My own involvement with the Pittsfield transformer operation began in 1966 when I joined the High Voltage Laboratory as a Development Engineer. Later, I became a Fortran computer programmer in the Engineering Depart¬ment, working with elaborate development and design pro¬grams having to do with transient voltage distribution in transformer windings and stray magnetic losses in transformer cores.

In 1987, when the Pittsfield transformer plant was closed down, I was employed as a Test Engineer working in Building 100, the cavernous main assembly building for large transformers. As such, I was to witness the somewhat bizarre spectacle of the "slow death" of this formerly bustling facility through the late summer and fall of that year.

In 1903, when the Stanley Electric Manufacturing Company in Pittsfield first became affiliated with the General Electric Company, it employed about 1700 and the population of Pittsfield was about 25,000. At the peak of employment in the Pittsfield G.E. operation, around 1950, the Pittsfield population had climbed to 53,000; however, the employment in "Transformers" had risen to 10,000!

Thus, General Electric had become a very signifi¬cant factor in the economic and the social fabric of Pittsfield and, indeed, in all of Berkshire County.

During the 1950's, several product lines related to transformers were moved to other locations around the country. This was the result of a vast reorganization and decentralization plan instituted by Ralph Cordiner, then the corporate head of the General Electric Company. As a consequence of this, the manufacture of capacitors was moved to Hudson Falls, New York; small distribution transformers were to be built in Hickory, North Carolina; and medium-sized power transformers were to be manufac¬tured in Rome, Georgia.

A "low point" in the history of transformers in Pittsfield came in 1961 when several high-ranking Gen¬eral Electric executives were caught up in a price-fixing scandal which involved major competitors such as Westinghouse. A real high point, however, was the con¬struction of Building 100, the huge transformer assembly and testing building, in 1968.

The men who headed the Pittsfield Transformer Oper¬ation during its eighty years of existence as a part of General Electric were (their actual titles changed from time to time as the corporate organization changed):

- Cummings C. Chesney

- Edward Wagner

- Louis Underwood

- Robert Paxton

- Francis Fairman

- William Ginn

- Raymond Smith

- Robert Gibson

- Robert Lewis

- Charles Meloun

- Bruce Roberts

- Nicholas Boraski

In 1972, the Company succeeded in obtaining the approval of the labor unions to switch hourly workers from incentive pay to "day rates" as a cost-cutting measure. This cost the average worker about $25.00 per week in lost wages. As a result, a critical drop in productivity led to "red ink" for the Transformer Oper¬ation. However, through the efforts of Bruce Roberts and Nicholas Boraski, the operation was eventually brought back into the black.

That was not enough to save the Transformer Opera¬tion, however. In 1974, the "oil crisis" in this coun¬try caused the traditional seven to eight percent annual increase in electrical power usage to disappear. Thus, the market for new large power transformers essentially vanished. The Pittsfield operation was never able to recover from that blow and, in 1987, with 1900 employees remaining, the General Electric Company decided to end the business of building transformers in Pittsfield.

Because of my background, as well as the nature of the business which is documented here, this historical outline is rather technical in nature. A Glossary of terms is included which serves to explain some of the more generally-used phrases pertinent to the design and manufacture of large power transformers.

This book is an edited version of a manuscript by the author which was prepared during 1995-96, and which is catalogued in the Local History collection of the Berkshire Athenaeum in Pittsfield.

T.J. Blalock Pittsfield, Mass. June, 1997

Acknowledgements

Several professionals formerly associated with the Pittsfield G.E. Transformer Operation provided valuable information, as well as encouragement, for this work. On topics relating to the engineering and design aspects of transformers and related equipment, these included John Church, Bell Cogbill, George Doucette, Harry Mason, Bill McNutt, Bob Mottershead, Al Rowe, George Sauer, Leonard van den Honert, and Don West.

Janice Calderwood provided information and material related to the Distribution Transformer Operation. Ed Kopf contributed valuable information on the early years of the Apprentice Program, as well as on many other as¬pects of life in the Pittsfield plant. William Coles provided details of Power House modifications over the years. Sam Sass contributed historical details related to the Stanley Library and other matters. R. Kelly Niederjohn and Stan Wilk provided information on the aspects of shipping huge transformers.

John Anderson contributed information regarding the Empire State Building lightning study, as well as the operation of the High Voltage Laboratory and Projects EHV and UHV. John Benedict contributed photos and other material related to the Building 9 High Voltage Labora- tory. Details relative to lightning arrester development and the operation of the Dufour cold-cathode oscillograph were provided by Tom Carpenter. Finally, much informa¬tion about the operation of the transformer testing faci¬lity was contributed by G.G. ("Pete") Kemp and by Tom Stanfield.

Access to archival material stored in the Pittsfield G.E. plant was provided by Tom Bednarz, William Carter, Jr., and Art Stringer.

Information taken from issues of the Pittsfield G.E. News and the 'Current News', as well as other archival material, was obtained with the assistance of the staff of the Local History Room of the Berkshire Athenaeum in Pittsfield; special thanks to Ruth Degenhardt in this regard. Postcard views of the early years of the Pitts¬field plant were reproduced from the collection of Judy Rupinski of Pittsfield.

Photographs from the collection of the Hall of Elec¬trical History of the Schenectady Museum Association, Schenectady, New York, were provided with the assistance of staff members John Anderson and Mary Kuykendall.

Also, "spiritual" support on matters relative to the publication of this work was provided by Paul Argentini.

Digital processing of G.E. photographic negatives was by Mark Swirsky of the Photo Shop in Pittsfield, MA.

Special recognition is due the late "Jimmy" Eulian, former High Voltage Laboratory technician, for providing many fascinating reminiscences from his forty-one years of employment in the Pittsfield G.E. plant.

Finally, the author wishes to give special recogni¬tion as well to two highly regarded professionals, now retired, who were very instrumental in the development of his career at the Pittsfield plant: Mr. Al Rohlfs, formerly with the High Voltage Laboratory, and Mr. Ed Uhlig, former Manager of Power Transformer Engineering in Pittsfield.

Chapter 1: The Early Years

"One day Mr. Whittlesey came to Barrington and I told him of my withdrawal from the Pittsburgh company. He asked me to come to Pittsfield and see some of his friends before I embarked anew. I came up to Pittsfield and met two sterling men, the late W.R. Plunkett and the late W.W. Gamwell. Mr. Plunkett called a meeting of bus¬inessmen at his residence on East Street. A dozen or so attended this meeting and we discussed the starting of a company to build transformers. Mr. Whittlesey then got subscriptions for $25,000. Two companies were organized. One, 'The Laboratory Company', with a small capital, in which Messrs. Chesney, Kelly and myself were the princi¬ple stockholders, and the other, 'The Manufacturing Com¬pany'. Mr. Chesney was chosen as the works manager of the manufacturing company and we started in." William Stanley The above quotation describes William Stanley's de¬parture from the Westinghouse Company in Pittsburgh, and the subsequent establishment of a transformer manufac¬turing plant in Pittsfield. Thus began the ninety-six year history of the manufacture of transformers in Pitts¬field which ended with the closing of the Large Trans¬former Operation of General Electric in 1987. The Stanley Laboratory Company originated in a build¬ing on Cottage Row (now Eagle Street) in Pittsfield, in 1890. The Stanley Electric Manufacturing Company went into operation on Clapp Avenue (now gone) in January of 1891. The Works Engineer was Cummings Chesney and the Shop Superintendent was John Kelman. The first shipment of "S.K.C." (Stanley-Kelly-Chesney) transformers left the shop on April 1, 1891. The last G.E. power transformer cleared "Test" in Building 100 in Pittsfield in October of 1987.

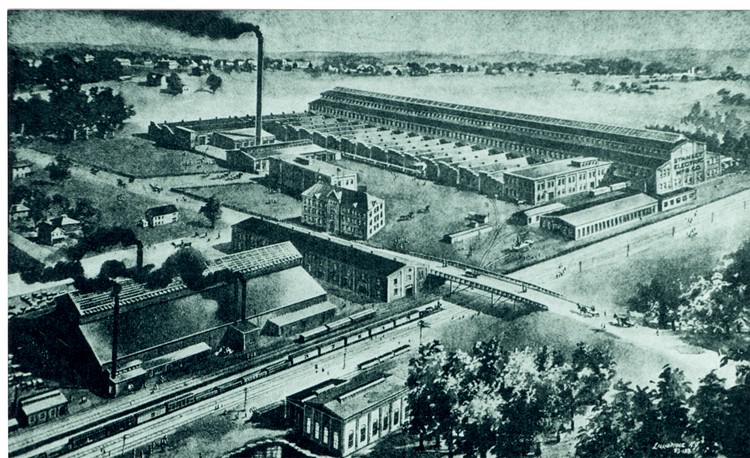

In 1892, the Clapp Avenue works employed sixteen people. Just one year later, a new plant employing 300 people went into operation on Renne Avenue! The Clapp Avenue plant was then used for the manufacture of switchboards. In 1895, the Stanley Electric Manufacturing Company absorbed the Stanley Laboratory Company. In 1899, a controlling interest in the manufacturing company was sold to John A. Roebling & Sons of Trenton, New Jersey (the builders of the Brooklyn Bridge), and the Stanley Company was reorganized under the corporate laws of the State of New Jersey. F.A.C. Perrine, who was related to the Roeblings by marriage, was named the new president of the company. There was much trepidation in Pittsfield as to whether the company would remain here or not. At this time, William Stanley "retired" and agreed to be a consultant "if needed". The company did remain in Pittsfield and, in 1900, under the direction of Perrine, construction began for a new plant in the Morningside section of the city. This was the beginning of what would eventually become the sprawling General Electric "main plant" complex. In 1901, the Morningside plant employed 1200 people, and both the Clapp Avenue and the Renne Avenue plants were abandoned. As mentioned, William Stanley became a "consultant" and went on to pursue other interests. One of his part¬ners, Cummings C. Chesney, became the Works Manager of the Morningside plant. The other partner, John Kelly, eventually quit when his Irish temperament would not allow him to work for a former competitor as the company became a subsidiary of General Electric in 1903. In that year, General Electric bought a controlling interest in the Stanley Company. At the same time, G.E. bought out the General Incandescent Arc Light Company of New York. These two companies were combined to form the "Stanley - G.I. Company". Once again, there was much trepidation in Pittsfield as to whether the company would remain here or not! However, in 1905, a massive expan¬sion of the Morningside plant was announced. In 1907, the plant became the Pittsfield Works of the General Electric Company and, by 1912, it covered an area which included 1,600,000 square feet of buildings. In 1915, one-sixth of the population of Pittsfield were em¬ployed in the plant, and it produced a total of 4,800,000 "horsepower" in transformers (roughly 3.6 million kilo¬watts worth). Also produced were flat irons, electric fans, and small motors.

According to an article in the October, 1908 issue of the General Electric Review, G.E. decided to use the Pittsfield plant for the manufacture of transformers in 1907 because the area afforded "opportunities for the acquisition of skilled labor of American extraction"! At first, only small standard transformers (known as Type 'H') were built in Pittsfield; however, in Septem¬ber of 1907, the Lynn (Mass.) Transformer Department was moved to Pittsfield and, by 1908, the Schenectady (N.Y.) transformer operation as well. Thus, in 1908, all G.E. transformers, with the exception of some small specialty types, were being manufactured in Pittsfield and the plant had increased in size by another fifty percent.