Archives:Transformers at Pittsfield, part 1: Difference between revisions

No edit summary |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock | Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock | ||

[[Image:Blalock - book cover.jpg|thumb|center|400px]] | |||

In 1886, [[William Stanley|William Stanley]] first successfully demonstrated the use of the [[Transformers|transformer]] in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts. | In 1886, [[William Stanley|William Stanley]] first successfully demonstrated the use of the [[Transformers|transformer]] in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts. | ||

In 1986, the [[General Electric (GE)|General Electric Company]] announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before. | In 1986, the [[General Electric (GE)|General Electric Company]] announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before. | ||

The technology associated with the design and manufacture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a foreign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands. | The technology associated with the design and manufacture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a foreign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands. | ||

| Line 405: | Line 405: | ||

Apprentices attended one two-hour class each working day. During the first year of the program, they learned how to operate every one of the machines in the shop. Then, they were sent to areas related to their particular line of interest: drafting, tool-making, pattern-making, maintenance, or engineering. There were both three and four year courses, and an entrance exam was mandatory. | Apprentices attended one two-hour class each working day. During the first year of the program, they learned how to operate every one of the machines in the shop. Then, they were sent to areas related to their particular line of interest: drafting, tool-making, pattern-making, maintenance, or engineering. There were both three and four year courses, and an entrance exam was mandatory. | ||

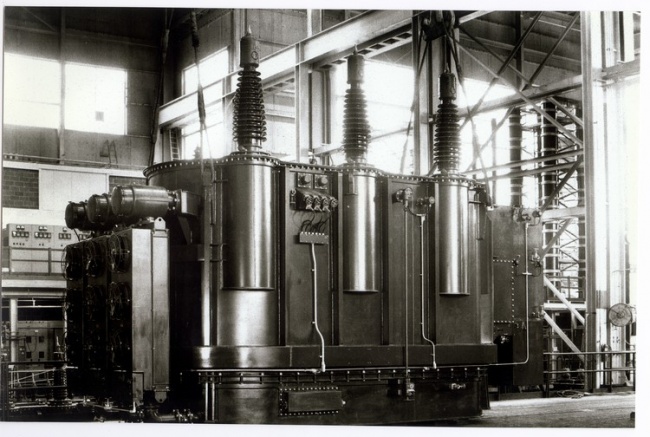

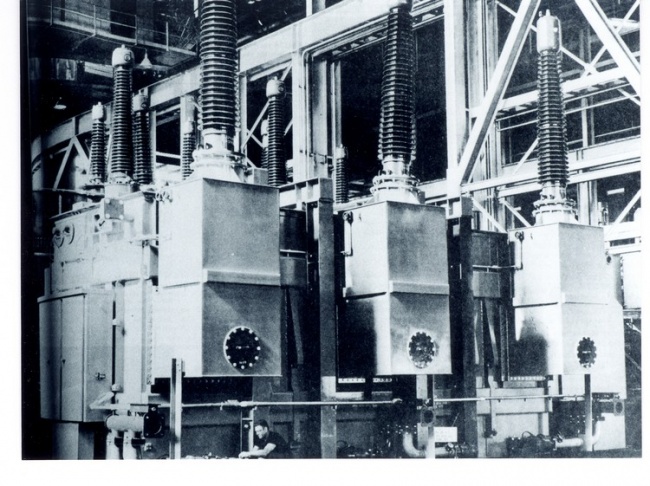

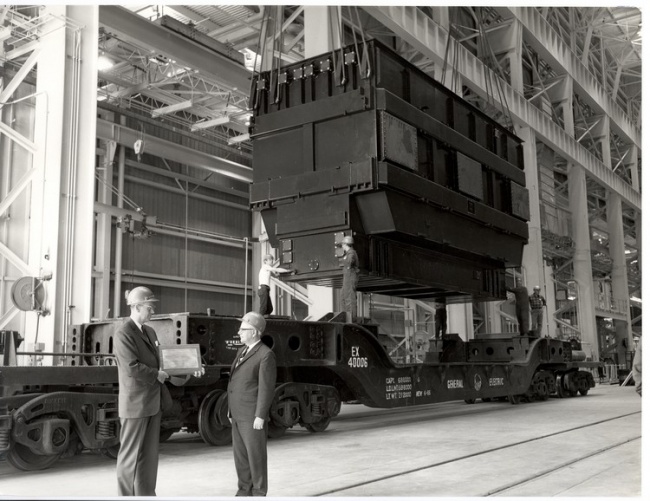

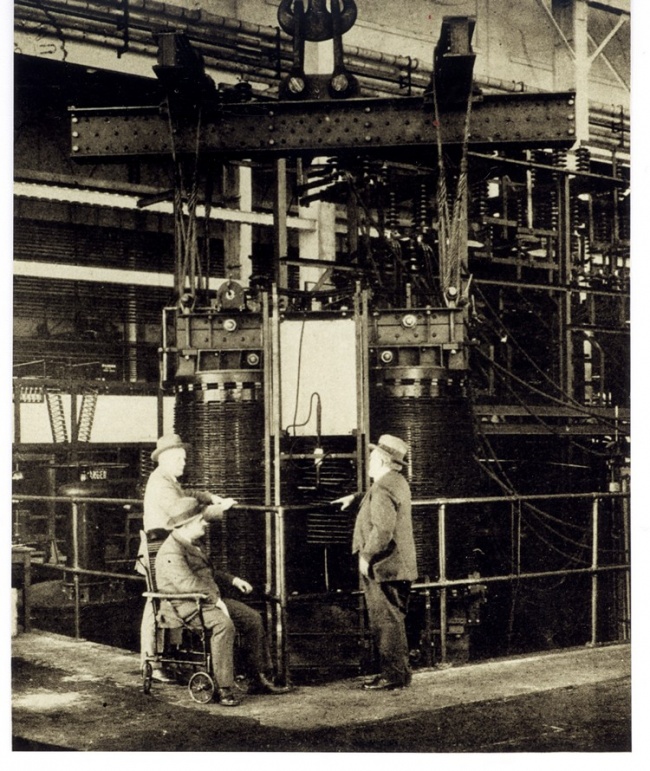

[[Image:Blalock - page | [[Image:Blalock - page 28.jpg|thumb|center|650px|Works Manager Cummings C. Chesney, along with Guiseppe Faccioli (in wheelchair) and W.S. Moody, inspect the largest single-phase transformer built as of 1926 (water-cooled, 60-cycles, 28,886-Kva, 100 tons for the Wallenpaupack Substation of the Pennsylvania Power and Light system; the three-phase bank of which it was to be a part was rated for 220-Kv to 66-Kv with an 11-Kv tertiary winding), G.E. Current News, January, 1926]] | ||

Apprentices were able to obtain experience working in any of the different departments in the plant: principally Power Transformer, Distribution Transformer, Regulators, Load Ratio Control, Foundry, Tool Room, Lightning Arresters, and Bushings. | Apprentices were able to obtain experience working in any of the different departments in the plant: principally Power Transformer, Distribution Transformer, Regulators, Load Ratio Control, Foundry, Tool Room, Lightning Arresters, and Bushings. | ||

| Line 1,637: | Line 1,637: | ||

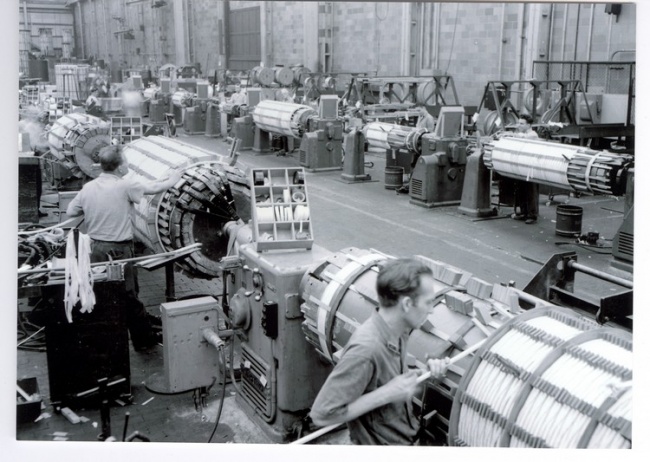

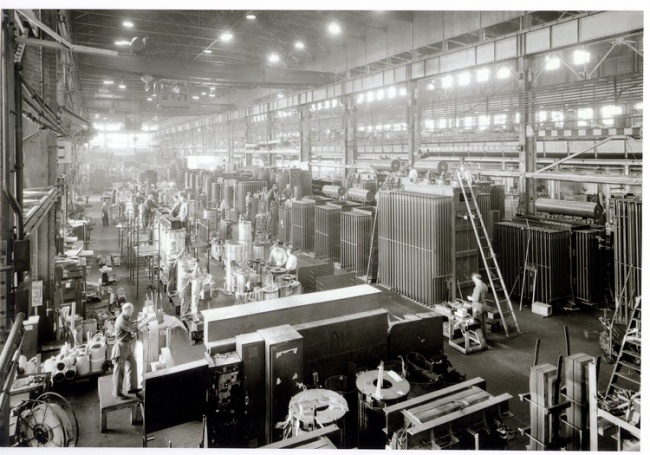

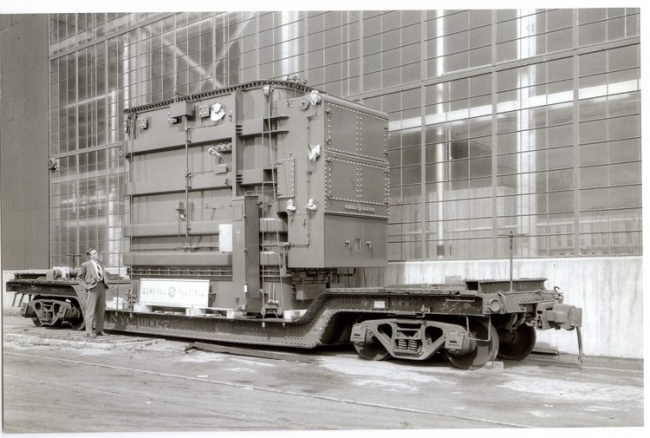

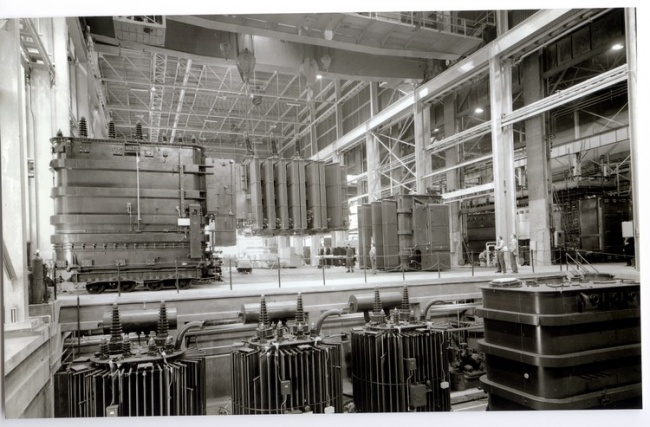

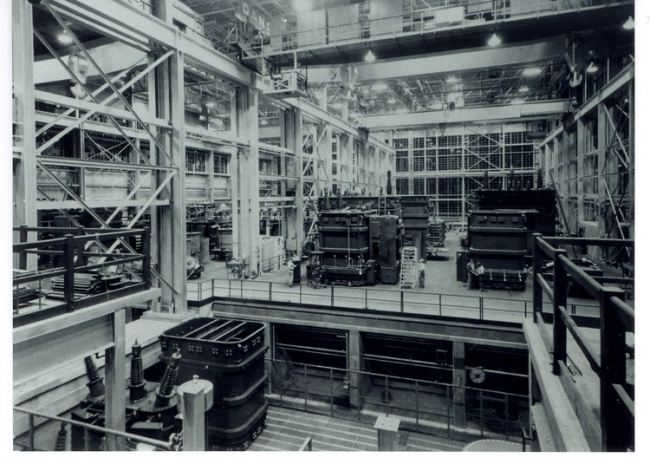

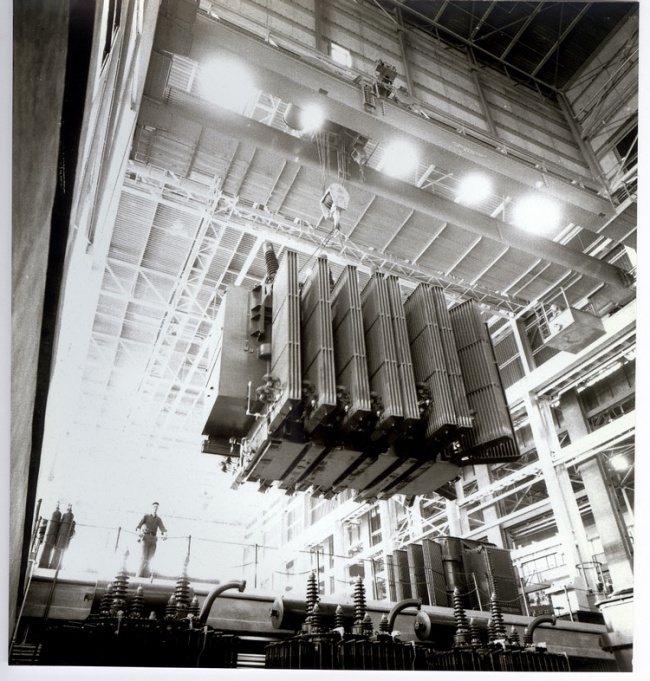

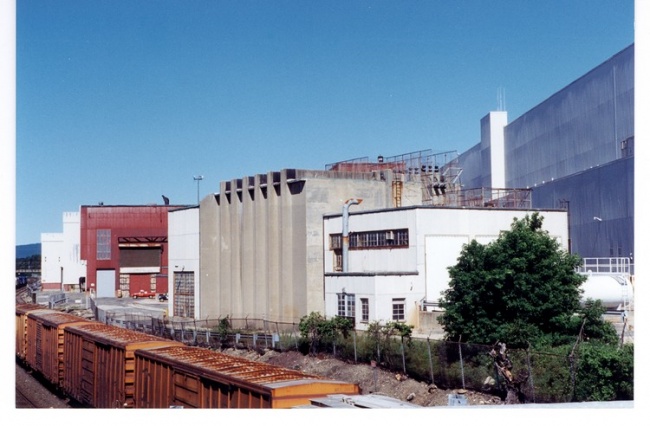

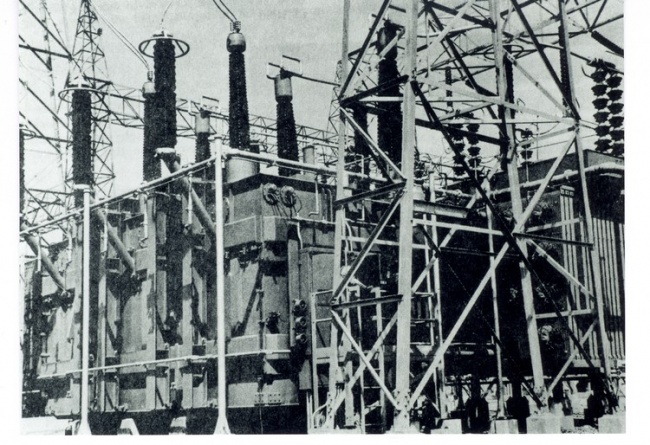

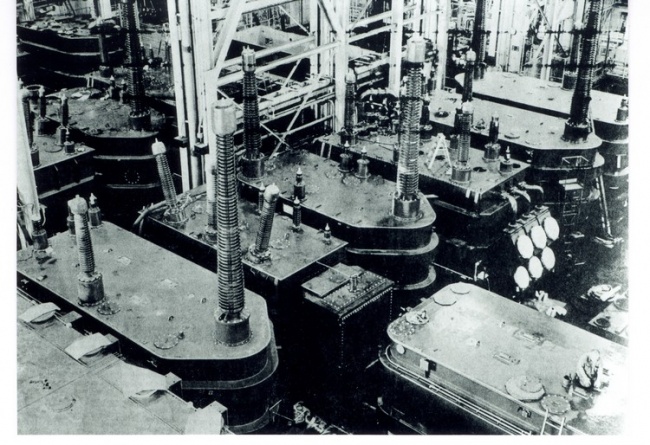

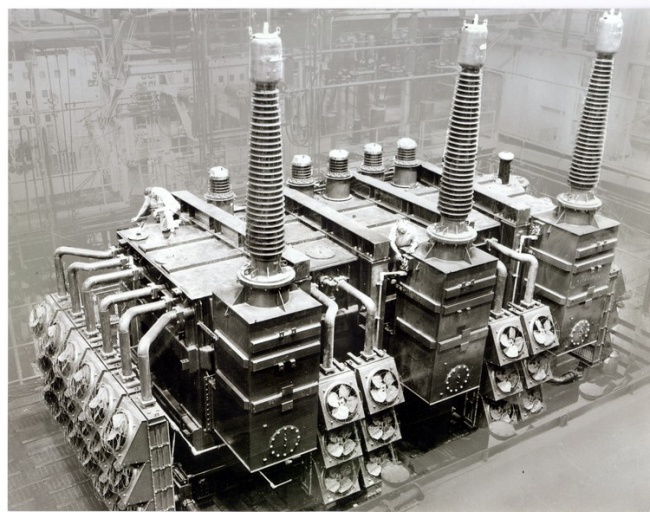

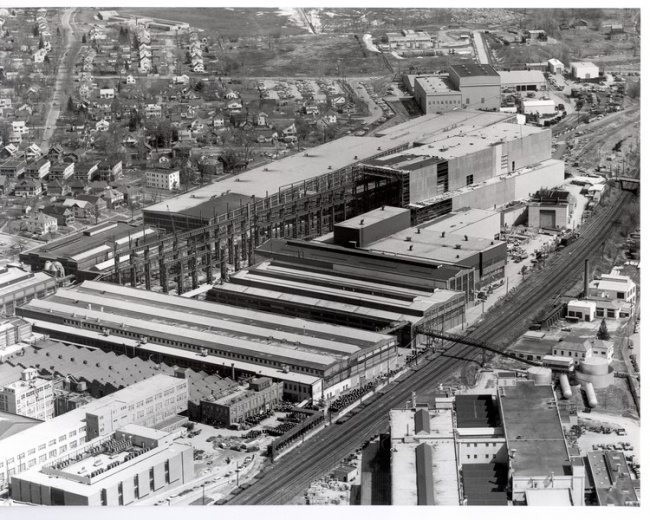

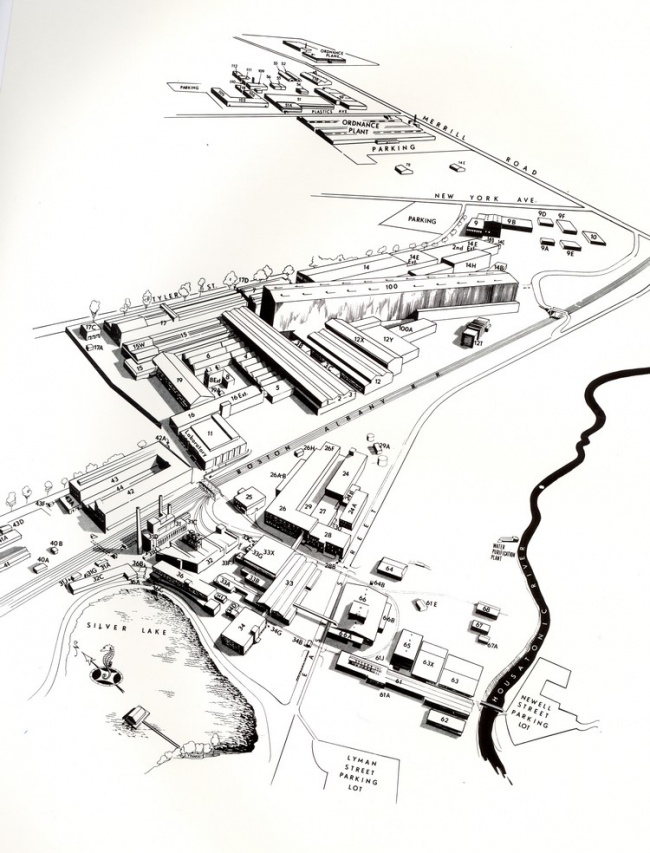

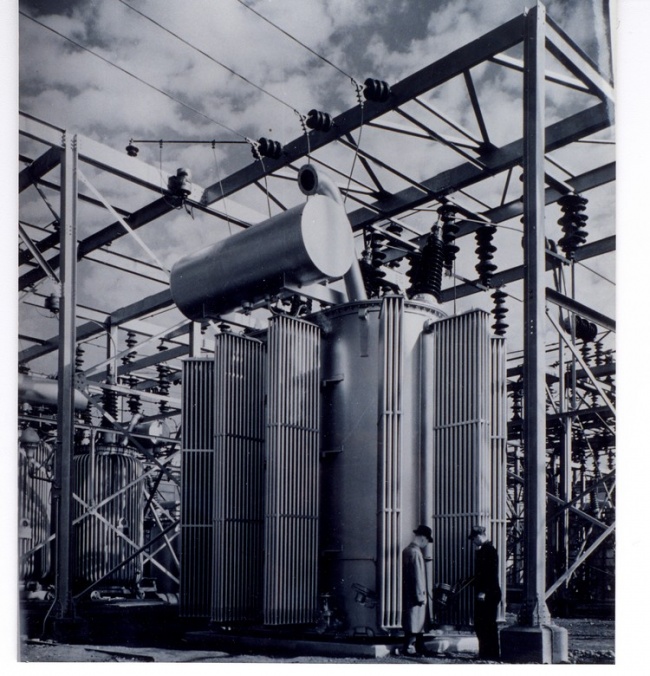

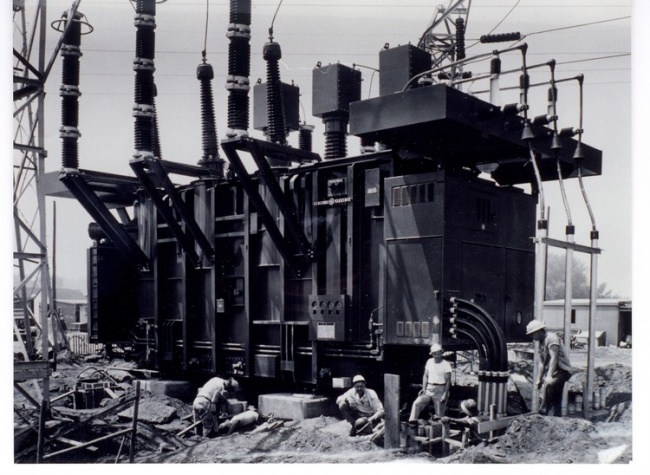

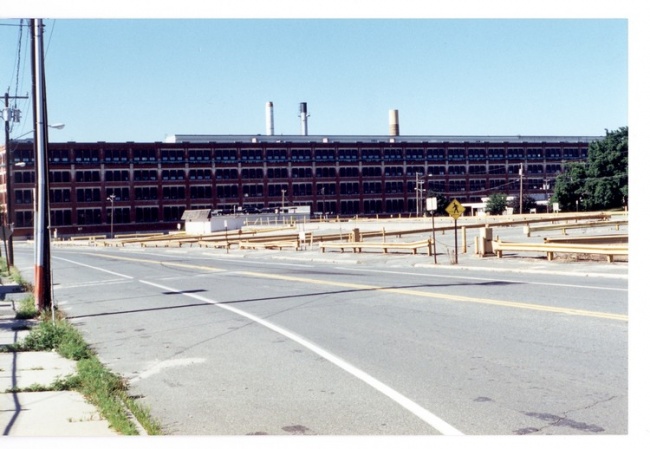

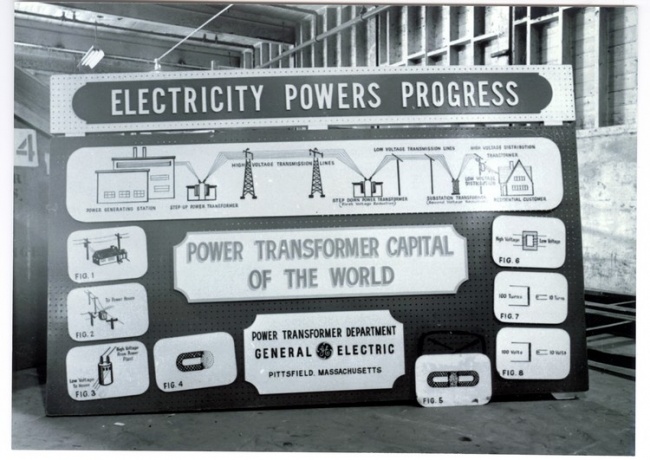

[[Image:Blalock - page 126.jpg|thumb|center|650px|"Power Transformer Capital of the World" (Pittsfield, Mass.); courtesy of General Electric Company (1975)]] | [[Image:Blalock - page 126.jpg|thumb|center|650px|"Power Transformer Capital of the World" (Pittsfield, Mass.); courtesy of General Electric Company (1975)]] | ||

To read more, continue to [[Archives:Transformers at Pittsfield, part 2|Transformers at Pittsfield, part 2]]. | To read more, continue to [[Archives:Transformers at Pittsfield, part 2|Transformers at Pittsfield, part 2]]. | ||

[[Category:Transformers|{{PAGENAME}}]] | |||

Revision as of 15:20, 3 January 2012

Preface

Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock

In 1886, William Stanley first successfully demonstrated the use of the transformer in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts.

In 1986, the General Electric Company announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before.

The technology associated with the design and manufacture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a foreign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands.

My own involvement with the Pittsfield transformer operation began in 1966 when I joined the High Voltage Laboratory as a Development Engineer. Later, I became a Fortran computer programmer in the Engineering Department, working with elaborate development and design programs having to do with transient voltage distribution in transformer windings and stray magnetic losses in transformer cores.

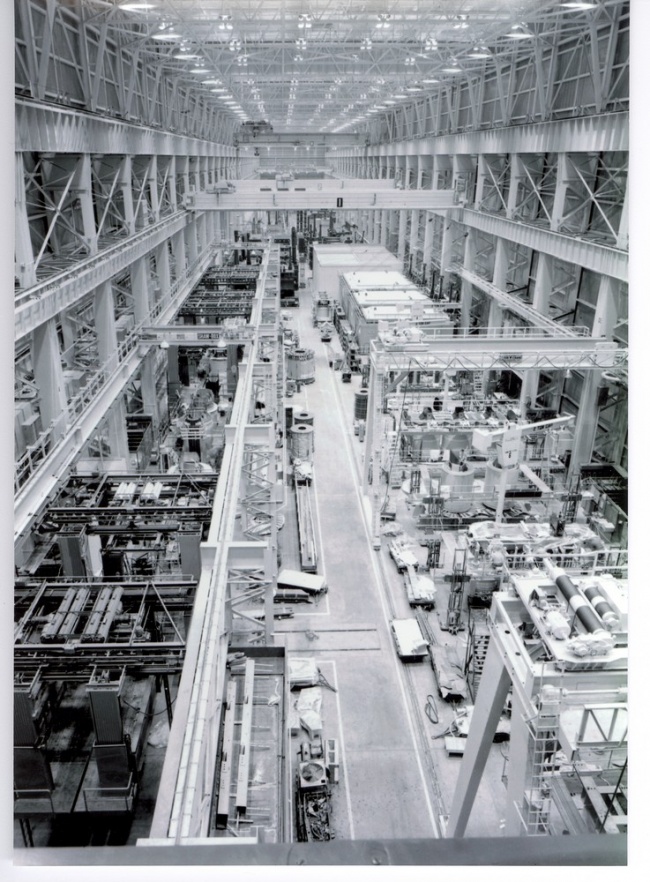

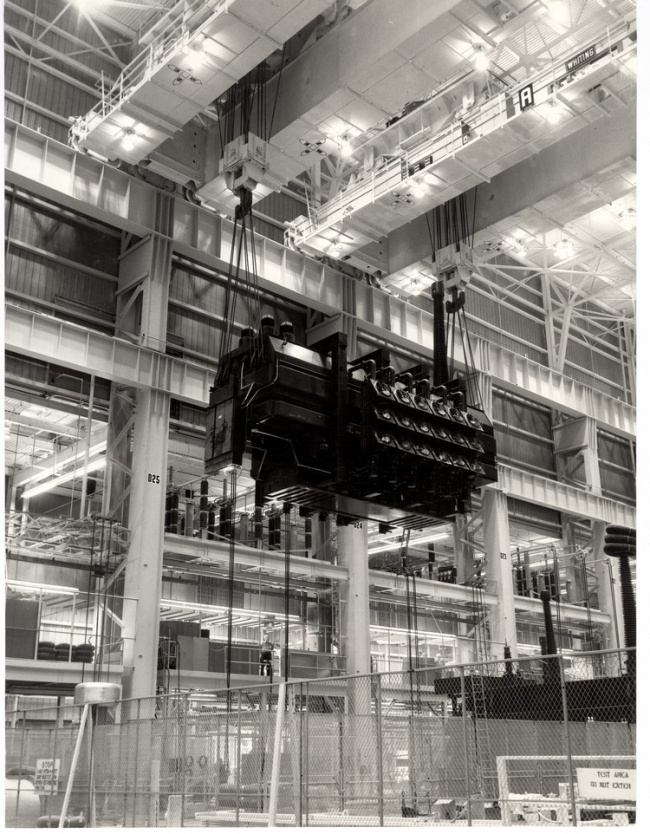

In 1987, when the Pittsfield transformer plant was closed down, I was employed as a Test Engineer working in Building 100, the cavernous main assembly building for large transformers. As such, I was to witness the somewhat bizarre spectacle of the "slow death" of this formerly bustling facility through the late summer and fall of that year.

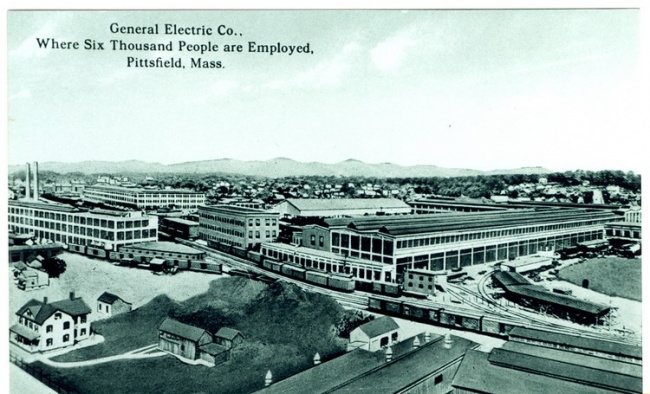

In 1903, when the Stanley Electric Manufacturing Company in Pittsfield first became affiliated with the General Electric Company, it employed about 1700 and the population of Pittsfield was about 25,000. At the peak of employment in the Pittsfield G.E. operation, around 1950, the Pittsfield population had climbed to 53,000; however, the employment in "Transformers" had risen to 10,000!

Thus, General Electric had become a very significant factor in the economic and the social fabric of Pittsfield and, indeed, in all of Berkshire County.

During the 1950's, several product lines related to transformers were moved to other locations around the country. This was the result of a vast reorganization and decentralization plan instituted by Ralph Cordiner, then the corporate head of the General Electric Company. As a consequence of this, the manufacture of capacitors was moved to Hudson Falls, New York; small distribution transformers were to be built in Hickory, North Carolina; and medium-sized power transformers were to be manufactured in Rome, Georgia.

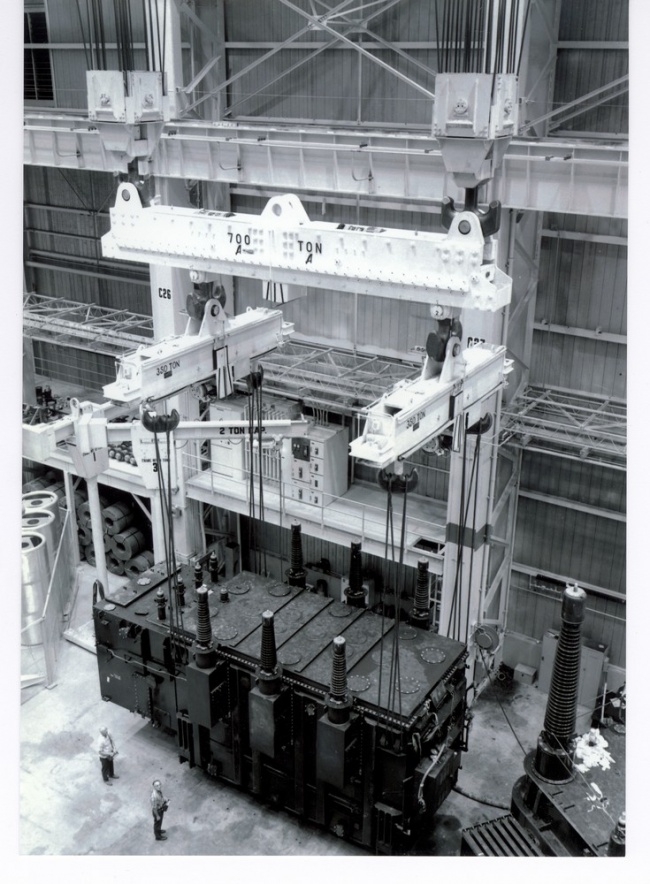

A "low point" in the history of transformers in Pittsfield came in 1961 when several high-ranking General Electric executives were caught up in a price-fixing scandal which involved major competitors such as Westinghouse. A real high point, however, was the construction of Building 100, the huge transformer assembly and testing building, in 1968.

The men who headed the Pittsfield Transformer Operation during its eighty years of existence as a part of General Electric were (their actual titles changed from time to time as the corporate organization changed):

- Cummings C. Chesney

- Edward Wagner

- Louis Underwood

- Robert Paxton

- Francis Fairman

- William Ginn

- Raymond Smith

- Robert Gibson

- Robert Lewis

- Charles Meloun

- Bruce Roberts

- Nicholas Boraski

In 1972, the Company succeeded in obtaining the approval of the labor unions to switch hourly workers from incentive pay to "day rates" as a cost-cutting measure. This cost the average worker about $25.00 per week in lost wages. As a result, a critical drop in productivity led to "red ink" for the Transformer Operation. However, through the efforts of Bruce Roberts and Nicholas Boraski, the operation was eventually brought back into the black.

That was not enough to save the Transformer Operation, however. In 1974, the "oil crisis" in this country caused the traditional seven to eight percent annual increase in electrical power usage to disappear. Thus, the market for new large power transformers essentially vanished. The Pittsfield operation was never able to recover from that blow and, in 1987, with 1900 employees remaining, the General Electric Company decided to end the business of building transformers in Pittsfield.

Because of my background, as well as the nature of the business which is documented here, this historical outline is rather technical in nature. A Glossary of terms is included which serves to explain some of the more generally-used phrases pertinent to the design and manufacture of large power transformers.

This book is an edited version of a manuscript by the author which was prepared during 1995-96, and which is catalogued in the Local History collection of the Berkshire Athenaeum in Pittsfield.

T.J. Blalock Pittsfield, Mass. June, 1997

Acknowledgements

Several professionals formerly associated with the Pittsfield G.E. Transformer Operation provided valuable information, as well as encouragement, for this work. On topics relating to the engineering and design aspects of transformers and related equipment, these included John Church, Bell Cogbill, George Doucette, Harry Mason, Bill McNutt, Bob Mottershead, Al Rowe, George Sauer, Leonard van den Honert, and Don West.

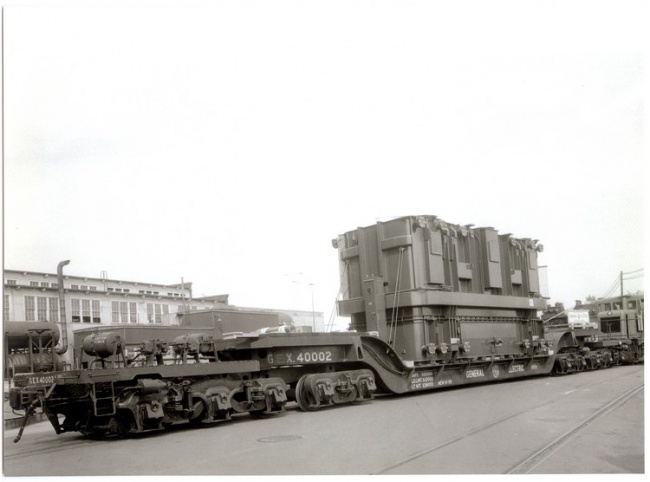

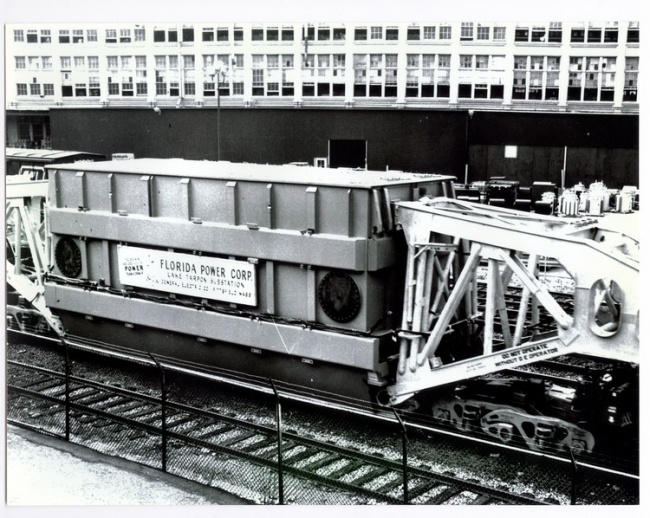

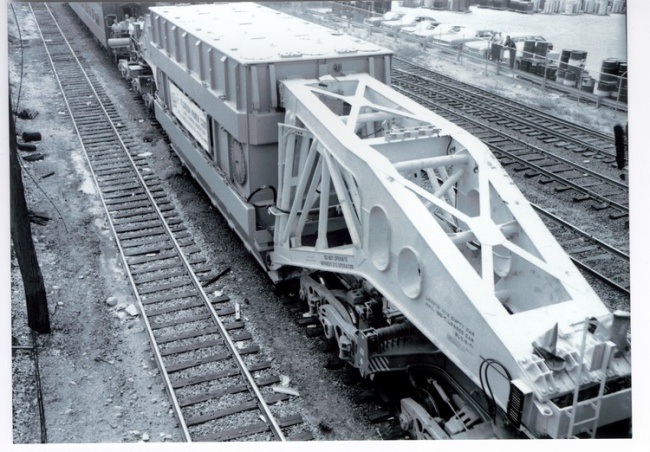

Janice Calderwood provided information and material related to the Distribution Transformer Operation. Ed Kopf contributed valuable information on the early years of the Apprentice Program, as well as on many other aspects of life in the Pittsfield plant. William Coles provided details of Power House modifications over the years. Sam Sass contributed historical details related to the Stanley Library and other matters. R. Kelly Niederjohn and Stan Wilk provided information on the aspects of shipping huge transformers.

John Anderson contributed information regarding the Empire State Building lightning study, as well as the operation of the High Voltage Laboratory and Projects EHV and UHV. John Benedict contributed photos and other material related to the Building 9 High Voltage Laboratory. Details relative to lightning arrester development and the operation of the Dufour cold-cathode oscillograph were provided by Tom Carpenter. Finally, much information about the operation of the transformer testing facility was contributed by G.G. ("Pete") Kemp and by Tom Stanfield.

Access to archival material stored in the Pittsfield G.E. plant was provided by Tom Bednarz, William Carter, Jr., and Art Stringer.

Information taken from issues of the Pittsfield G.E. News and the 'Current News', as well as other archival material, was obtained with the assistance of the staff of the Local History Room of the Berkshire Athenaeum in Pittsfield; special thanks to Ruth Degenhardt in this regard. Postcard views of the early years of the Pittsfield plant were reproduced from the collection of Judy Rupinski of Pittsfield.

Photographs from the collection of the Hall of Electrical History of the Schenectady Museum Association, Schenectady, New York, were provided with the assistance of staff members John Anderson and Mary Kuykendall.

Also, "spiritual" support on matters relative to the publication of this work was provided by Paul Argentini.

Digital processing of G.E. photographic negatives was by Mark Swirsky of the Photo Shop in Pittsfield, MA.

Special recognition is due the late "Jimmy" Eulian, former High Voltage Laboratory technician, for providing many fascinating reminiscences from his forty-one years of employment in the Pittsfield G.E. plant.

Finally, the author wishes to give special recognition as well to two highly regarded professionals, now retired, who were very instrumental in the development of his career at the Pittsfield plant: Mr. Al Rohlfs, formerly with the High Voltage Laboratory, and Mr. Ed Uhlig, former Manager of Power Transformer Engineering in Pittsfield.

Chapter 1: The Early Years

"One day Mr. Whittlesey came to Barrington and I told him of my withdrawal from the Pittsburgh company. He asked me to come to Pittsfield and see some of his friends before I embarked anew. I came up to Pittsfield and met two sterling men, the late W.R. Plunkett and the late W.W. Gamwell. Mr. Plunkett called a meeting of businessmen at his residence on East Street. A dozen or so attended this meeting and we discussed the starting of a company to build transformers. Mr. Whittlesey then got subscriptions for $25,000. Two companies were organized. One, 'The Laboratory Company', with a small capital, in which Messrs. Chesney, Kelly and myself were the principle stockholders, and the other, 'The Manufacturing Company'. Mr. Chesney was chosen as the works manager of the manufacturing company and we started in."

The above quotation describes William Stanley's departure from the Westinghouse Company in Pittsburgh, and the subsequent establishment of a transformer manufacturing plant in Pittsfield. Thus began the ninety-six year history of the manufacture of transformers in Pittsfield which ended with the closing of the Large Transformer Operation of General Electric in 1987.

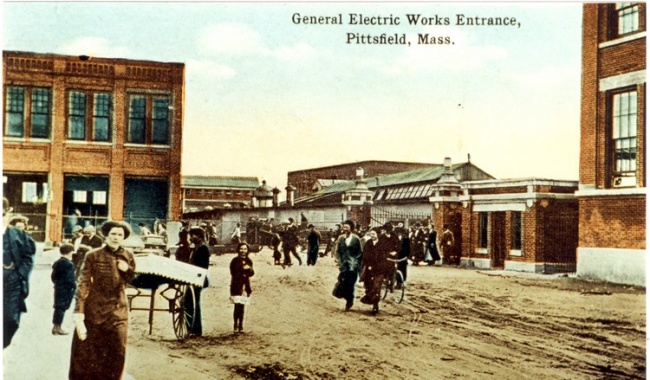

The Stanley Laboratory Company originated in a building on Cottage Row (now Eagle Street) in Pittsfield, in 1890. The Stanley Electric Manufacturing Company went into operation on Clapp Avenue (now gone) in January of 1891. The Works Engineer was Cummings Chesney and the Shop Superintendent was John Kelman. The first shipment of "S.K.C." (Stanley-Kelly-Chesney) transformers left the shop on April 1, 1891.

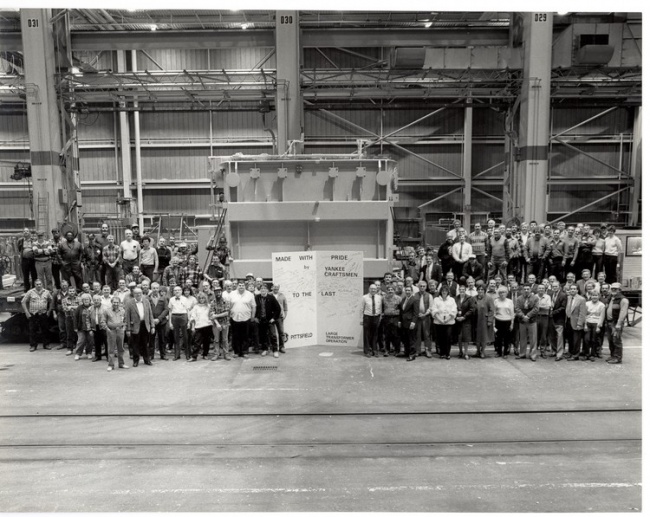

The last G.E. power transformer cleared "Test" in Building 100 in Pittsfield in October of 1987.

In 1892, the Clapp Avenue works employed sixteen people. Just one year later, a new plant employing 300 people went into operation on Renne Avenue! The Clapp Avenue plant was then used for the manufacture of switchboards.

In 1895, the Stanley Electric Manufacturing Company absorbed the Stanley Laboratory Company. In 1899, a controlling interest in the manufacturing company was sold to John A. Roebling & Sons of Trenton, New Jersey (the builders of the Brooklyn Bridge), and the Stanley Company was reorganized under the corporate laws of the State of New Jersey. F.A.C. Perrine, who was related to the Roeblings by marriage, was named the new president of the company. There was much trepidation in Pittsfield as to whether the company would remain here or not. At this time, William Stanley "retired" and agreed to be a consultant "if needed".

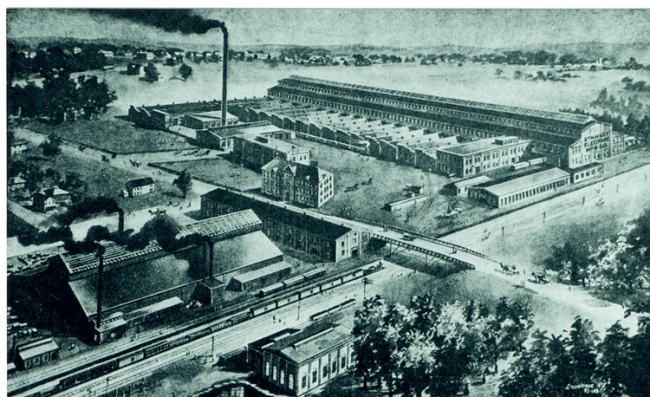

The company did remain in Pittsfield and, in 1900, under the direction of Perrine, construction began for a new plant in the Morningside section of the city. This was the beginning of what would eventually become the sprawling General Electric "main plant" complex. In 1901, the Morningside plant employed 1200 people, and both the Clapp Avenue and the Renne Avenue plants were abandoned.

As mentioned, William Stanley became a "consultant" and went on to pursue other interests. One of his partners, Cummings C. Chesney, became the Works Manager of the Morningside plant. The other partner, John Kelly, eventually quit when his Irish temperament would not allow him to work for a former competitor as the company became a subsidiary of General Electric in 1903.

In that year, General Electric bought a controlling interest in the Stanley Company. At the same time, G.E. bought out the General Incandescent Arc Light Company of New York. These two companies were combined to form the "Stanley - G.I. Company". Once again, there was much trepidation in Pittsfield as to whether the company would remain here or not! However, in 1905, a massive expansion of the Morningside plant was announced.

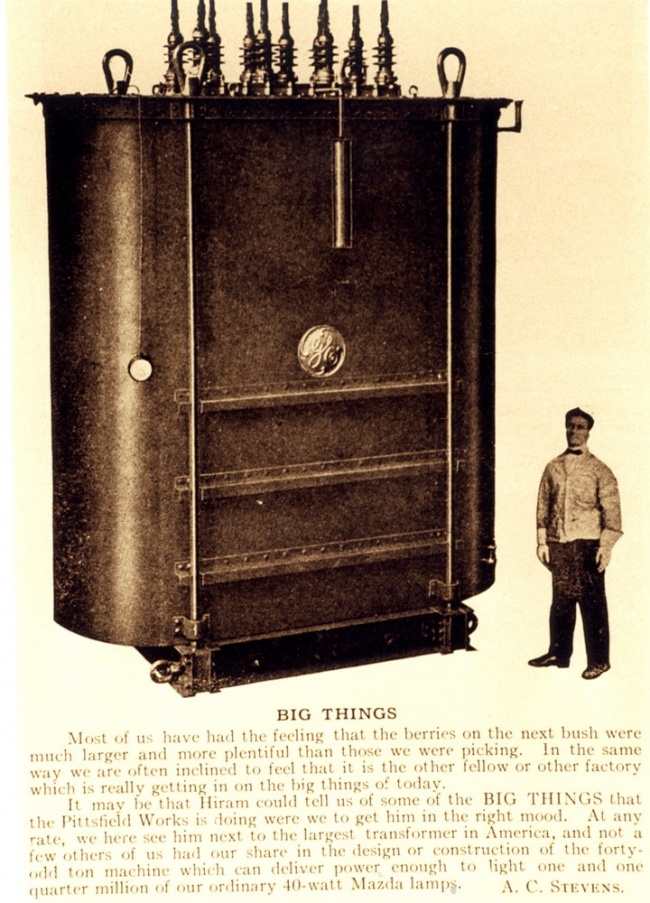

In 1907, the plant became the Pittsfield Works of the General Electric Company and, by 1912, it covered an area which included 1,600,000 square feet of buildings. In 1915, one-sixth of the population of Pittsfield were employed in the plant, and it produced a total of 4,800,000 "horsepower" in transformers (roughly 3.6 million kilowatts worth). Also produced were flat irons, electric fans, and small motors.

According to an article in the October, 1908 issue of the General Electric Review, G.E. decided to use the Pittsfield plant for the manufacture of transformers in 1907 because the area afforded "opportunities for the acquisition of skilled labor of American extraction"!

At first, only small standard transformers (known as Type 'H') were built in Pittsfield; however, in September of 1907, the Lynn (Mass.) Transformer Department was moved to Pittsfield and, by 1908, the Schenectady (N.Y.) transformer operation as well. Thus, in 1908, all G.E. transformers, with the exception of some small specialty types, were being manufactured in Pittsfield and the plant had increased in size by another fifty percent.

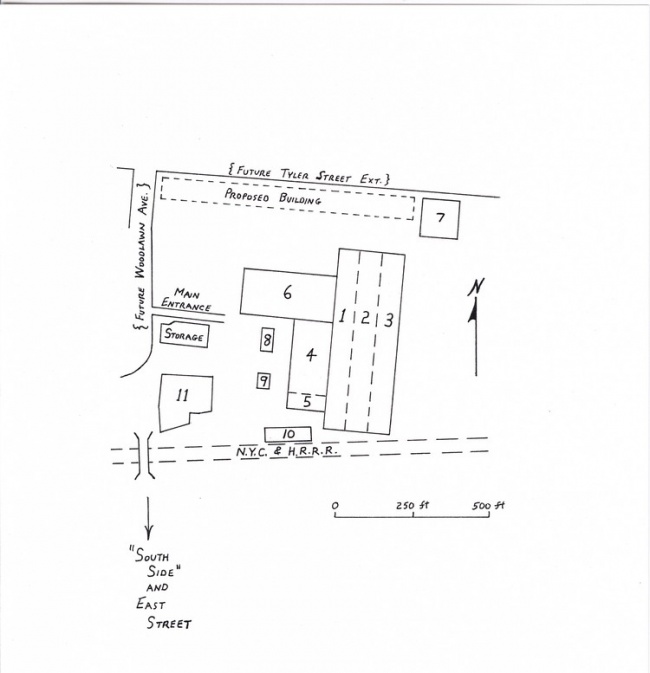

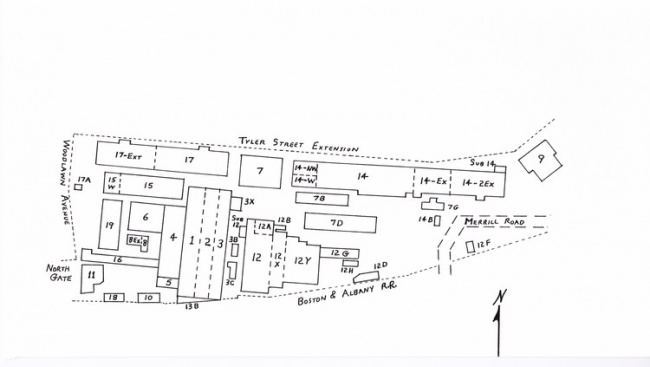

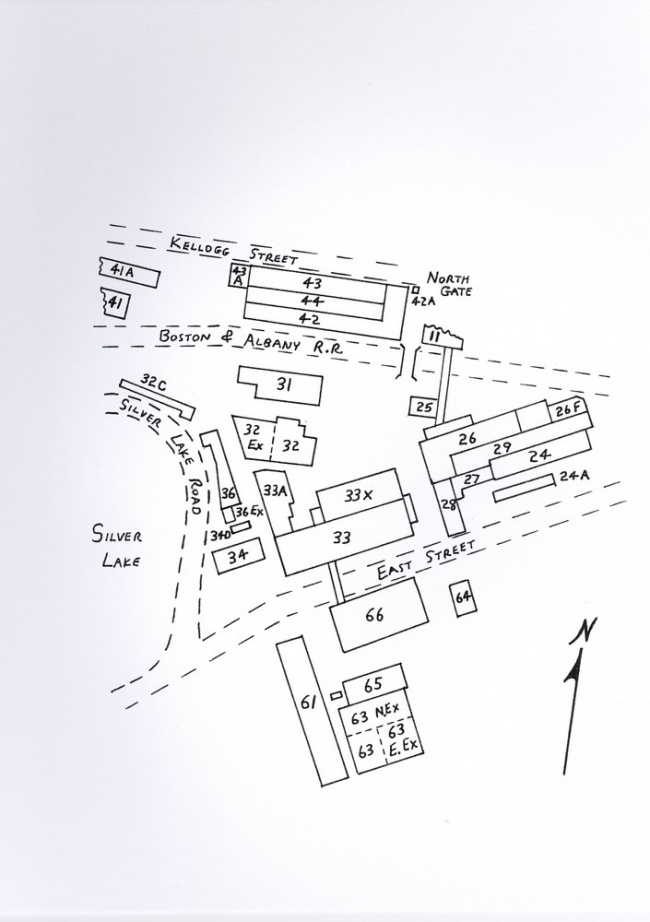

The preceding page shows the building layout of the plant in 1908, just after it became the Pittsfield G.E. Works. The area shown is that located north of the New. York Central and Hudson River Railroad tracks. This was actually the right-of-way for the Boston & Albany Railroad, which was owned by the NYC&HRRR. These tracks do still exist, and serve Conrail and Amtrak trains which run between Boston, Mass. and Albany, N.Y.

The identified buildings served the following functions in 1908:

Buildings 1-2-3

These were the main transformer assembly and testing bays. Building 1 was constructed in 1900, and Buildings 2 and 3 were added around the time that the plant became a part of G.E. These buildings still exist today.

Building 4

This was the main winding area for the larger sizes of transformers. It also still exists. This was also the assembly area for small types of transformers.

Building 5

This was the main shipping area. It was served by a railroad siding running along its south side; this siding also ran through the south end of the Building 1-2-3 complex. This building eventually housed offices and the "copper shop", and still exists.

Building 6

This was the area in which the various types of insulation (such as pressboard, etc.) needed in the transformers was prepared. It still exists.

Building 7

This was where the thin laminations of steel needed to build up the magnetic cores of the transformers were fabricated. This building served several other functions in later years. It still stands, but is somewhat derelict.

Building 8

This was the Laboratory building where the development of transformer insulation materials, and the high voltage testing of same, was carried on. It still stands, but is also somewhat derelict.

Building 9

This no longer exists; it was a storage facility for the oils used in transformers for insulation and cooling.

Building 10

This was identified as a Carpenter and Pattern Shop, and no Longer exists.

Building 11

This was the Brass Foundry and Tank Shop, for the production of brass electrical fittings and the fabrication of the iron tanks which held the working parts of the transformers. The site is presently occupied by a new Building 11 dating from the 1960's.

The building near the Main Entrance, designated as "Storage", was soon after replaced by Building 16; this became the main Engineering and Drafting building for the transformer operation. It still stands.

Around this same time (1909-10), an addition known as Building 13 was constructed at the south end of the Building 1-2-3 complex; it is now gone. Also, a new Tank Shop (Building 14) was constructed to the east of Building 7, and a new shop for core steel (Building 15) was added to the north of Buildings 4 and 6. In 1914, a larger transformer assembly and testing facility known as Building 12 was begun to the east of Building 3. All of these latter buildings still exist.

Also, the area designated as "Proposed Building" became Building 17. Originally, this also served as a Tank Shop; however, for many years after that, it was the main winding facility where most of the large transformer windings were constructed on winding "lathes". This building still stands.

In 1908, the major buildings on the "South Side" of the railroad tracks were:

- an iron foundry, using cupola-type melting furnaces, for the production of cast iron transformer tanks (in later years, the tanks would be made of welded steel plates). This was on the site of the present Building 33.

- a building for producing molded-type insulations, and a building for the kiln-drying of wood insulation materials.

- a building for the manufacture of fan motors. This became the site of Building 26 which was razed in 1988.

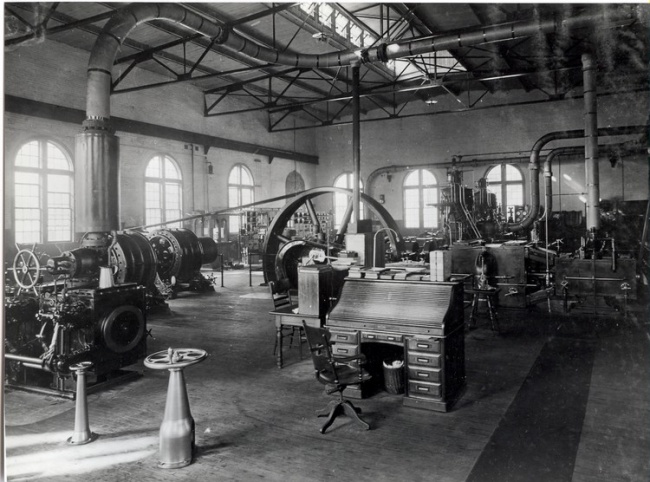

- the original Power House for the plant. This became Building 31 which still stands, but is now derelict.

The 1908 layout of the "North Side" of the plant shows a curve in the street line to the north of the railroad bridge. Eventually, this became the intersection of Woodlawn Avenue and Kellogg Street. Also, this became the site of the "North Gate", a new main entrance to the plant.

The establishment of North Gate coincided with the construction of a main office building, Building 42, in 1911. This building was directly across from (to the west of) Building 11. Two years later, an addition was constructed running west along Kellogg Street. This was known as Building 43 and contained more office space. Both Buildings 42 and 43 still exist, but are unused.

Along with the main offices for the plant, there was some production area in Building 42; this was mainly devoted to the manufacture of heating devices. Also, there was a Telegraph Office with connections to both the Postal Company and Western Union, along with a line directly to the Schenectady G.E. plant. In addition to offices, Building 43 contained production area devoted to the manufacture of lightning arresters, a tool room, and space for the training of Apprentices.

Chapter 2: The Electric Power System

An interesting aspect of the electric power system in the Morningside plant is that it was not the standard three-phase type of power which is universally used now. The generation and distribution was via a system known as "two-phase".

William Stanley designed and built a great deal of two-phase equipment during the 1890's, partly because of a belief in its superiority over three-phase, but also to avoid patent infringement problems with General Electric and Westinghouse who both used the three-phase system.

In fact, three-phase is decidedly superior for power distribution purposes. Thus, the old two-phase systems have gradually faded out of existence. However, two-phase power was so firmly entrenched in the Pittsfield plant that remnants of it still exist today! This has to do with the existence of old two-phase motors which have never been replaced.

Three-phase power consists of three alternating-type voltages intermingled on three wires. It can be proven mathematically that it is the most efficient system for transferring large amounts of electric power from one place to another, considering the weight of copper which is necessary to do so.

However, in the early 1890's, the understanding of the complexities of "polyphase" (more than one phase) systems was still limited. In particular, there were problems in learning how to regulate the three voltages in a three-phase system in order to keep them all at a constant level. Varying voltage levels severely reduced the expected life of the early incandescent lamps.

Since the basic two-phase system consisted of two completely separate two-wire single-phase circuits, independent regulation of each circuit was relatively simple. This was the main reason that Stanley, as well as others, advocated the use of the two-phase system.

The two-phase system which was adopted in the plant in Pittsfield was somewhat unusual in that only three wires were used instead of four; one wire served as a common for the two single-phase circuits. The two voltages in a two-phase system are at ninety electrical degrees to each other.

Thus, when one wire is used as a common return, the current which flows in it is 41 percent greater than the current in the other two wires, even when feeding a balanced load such as a motor.

Because of this, feeder cable runs in the plant often consisted of two cables of one size plus a third cable which was roughly fifty percent larger in cross-section. However, sometimes it was apparently easier to deal with just one size of cable; in such situations, four cables were run and two were paralleled to use as the common. Obviously, this led to some waste in the total amount of copper used.

The original plant Power House dated from 1900 when the Stanley Company moved from Renne Avenue and Clapp Avenue in Pittsfield. The first generators installed were two-phase machines. By 1950, there were still a couple of two-phase generators (of later vintage) being held in reserve for emergencies. However, the active generation by that time was all three-phase. Over the years, phase-changing transformers had' been installed in some of the electrical substations around the plant to provide two-phase power to old motors still in use. As of today (1997), there are still one or two of these special transformers in use for this same purpose!

The windings of the phase-changing transformers were of a special design developed by G.E. engineers which would have allowed the transformers to be converted to straight three-phase transformers at some pertinent time. Doubtless, these engineers would have been surprised if they knew that such a changeover was destined never to happen!

The two-phase generation and distribution voltage was originally chosen to be 2300 volts, and this was never changed through the years. In 1900, and for some years after that, all of the generators in the Power House were belt-driven from reciprocating steam engines. In later years, of course, the old engines were slowly replaced by steam turbines, and the generators replaced by more modern designs.

The Power House was erected near to Silver Lake, so as to have an adequate supply of cooling water for condensing the steam. Eventually, this became known as Building 31.

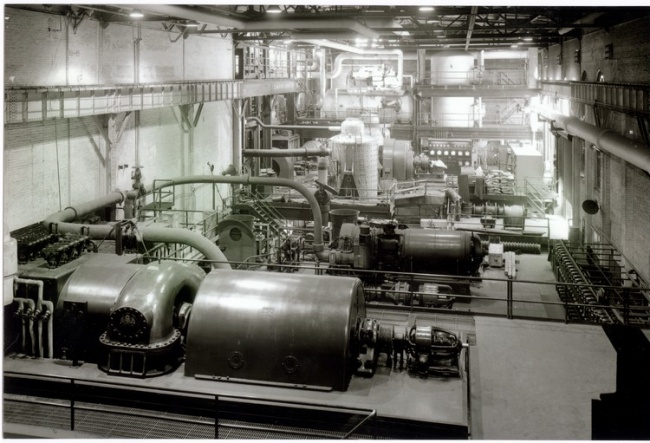

Synopsis of Power House History

- 1900 - original power house constructed

- 1907, 08 - two 500-kw, two-phase vertical turbines installed

- 1910, 11 - two 1500-kw, two-phase four-stage turbines installed

- 1915 - 2500-kw, two-phase horizontal turbine installed

- 1930's - experimental mercury turbine installed

- 1941 - 3000-kw, two-phase horizontal turbine installed

- 1946 - two 7500-kw, three-phase horizontal turbines installed

- 1950 - 7500-kw, three-phase mercury turbine installed

- 1960 - mercury turbine removed

- 1970 - power house ceases generation; provides steam only

For some time prior to 1970, General Electric had a cogeneration agreement with the Western Massachusetts Electric Company whereby they purchased any excess power available from the Power House.

During the 1980's, it was determined that the Power House could not be brought up to existing pollution standards. Accordingly, G.E. instigated the construction of a new cogeneration plant on property which they owned to the east of the main plant. The plant Power House was then completely shut down. Today, the new plant sells electric power to Northeast Utilities, and sells steam for heating purposes to General Electric.

When in full operation, the plant Power House provided high pressure process steam, low pressure heating steam, and compressed air for manufacturing use.

By 1915, major substations in the plant were located in, or near, Buildings 4, 12, 15, 41, 42, and 43 on the North Side, and Buildings 26, 32, and 33 on the South Side. In addition, there was a separate set of feeders from the Power House to the main transformer testing facility in Building 12 (because of the large amount of power required by that operation).

As a matter of interest, all of the steel buildings in the plant were connected electrically by means of a large diameter copper cable; this, in turn, connected to a grounding plate at the bottom of nearby Silver Lake!

The substations served to step down the voltage from the Power House to:

- 110/220 volts single-phase

- 440 volts three-phase

- 550 volts two-phase

The three-phase system, as it evolved in the plant, operated at 13,800 volts (13.8-kv). In 1936, switch-gear was installed in the Power House in anticipation of an interconnection between the plant and the lines of "The New England and Turner's Falls Power Company". These were 115-kv lines which terminated at the Silver Lake Station of the Pittsfield Electric Company.

Two Pittsfield-built transformers were installed near Silver Lake. These had dual secondary windings. One winding connected with the 13.8-kv three-phase plant power system, while the other winding connected: with the 2300-volt two-phase plant power system (via a phase-changing winding connection).

The mercury turbine installation referred to above was the result of development work in the use of mercury vapor as a more efficient alternative to high pressure steam for driving turbines. Complications in the technology, however, led to its eventual abandonment (today, such a concept would probably be unacceptable due to the usage of vast amounts of toxic mercury!).

Chapter 3: The "Current News"

During the years 1913 through 1931, the Pittsfield G.E. plant newsletter was known as the "Current News". This was a glossy magazine-style publication which was printed on a monthly basis. It is not known exactly why it ceased publication in 1931, but it may have been a casualty of the Great Depression; it was probably fairly costly to produce. After a lapse of three years, it was replaced by a newspaper-style publication known simply as the "Pittsfield G.E. News".

The following is a compendium of interesting items taken from the "Current News". The emphasis is on technical developments related to transformers as well as items relating to expansions and changes within the plant. However, there are also miscellaneous "tidbits" of information which deal with people-related and community types of events.

1914:

- The High Voltage Engineering Laboratory was formed.

One of the many brilliant technical men associated with the Pittsfield plant over the years was A.M. Gifford, who headed the Laboratory operation for 45 years. Gifford was instrumental in the quest for the development of improved transformer core steel which drastically cut magnetic losses.

Known as silicon steel, this material was actually first developed in England in 1907 by Sir Robert Hadfield.

Gifford also promoted the use of Pyranol, a non-flammable transformer insulating fluid which was eventually banned in the 1970's, being a suspected carcinogen.

He was heavily involved in development work through the years which eventually led to the creation of the G.E. Plastics Operation, the only vestige of General Electric remaining in Pittsfield in 1997.

Finally, he was instrumental in the development of Calrod heating units, still used in conventional electric ranges and ovens. For many years, these were manufactured in a building on Columbus Avenue in Pittsfield.

- Construction was begun on Building 12 which was to become the main transformer assembly and testing facility for large transformers.

- A new Works Restaurant, located on Kellogg Street near the North Gate, was opened.

- Flatirons were being manufactured in a section of Building 43.

- The G.E. Band was organized.

- The quality of the plant's drinking water was being questioned!

1915:

- An addition (known as "17Ext") was made to Building 17, located near the corner of Tyler Street and Woodlawn Avenue. Originally built in 1910, Building 17 had become the Tank Shop where steel transformer tanks were fabricated. The original Tank Shop had been on the site of the present Building 11.

- William Stanley died in Great Barrington.

- G.E. sponsored an elaborate production of Gilbert and Sullivan's "The Mikado", at the Colonial Theatre on South Street in Pittsfield.

- The Works Restaurant began serving breakfasts in addition to other meals.

1917:

- The manufacture of fans and motor armatures was begun in a building on Columbus Avenue in Pittsfield, which had been purchased in 1916.

- The first commercial testing of transformers in the new Building 12 facility was begun.

- Lightning arresters were being manufactured in Building 41, heating devices (including Calrod units) in Building 43, and small motors in Building 26.

1918:

- The General Electric Athletic Association, known as the G.E.A.A., was formed.

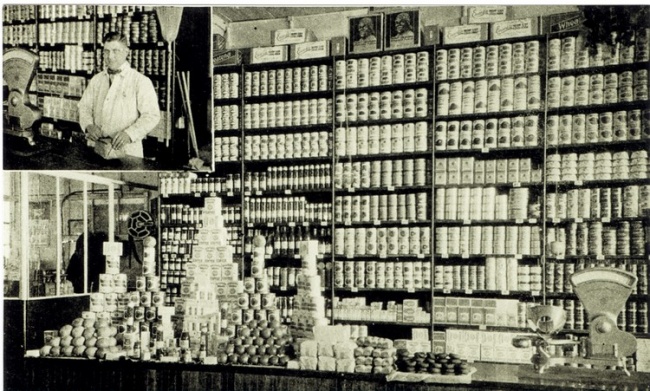

- A new Employees' Food Store was opened in Building 42.

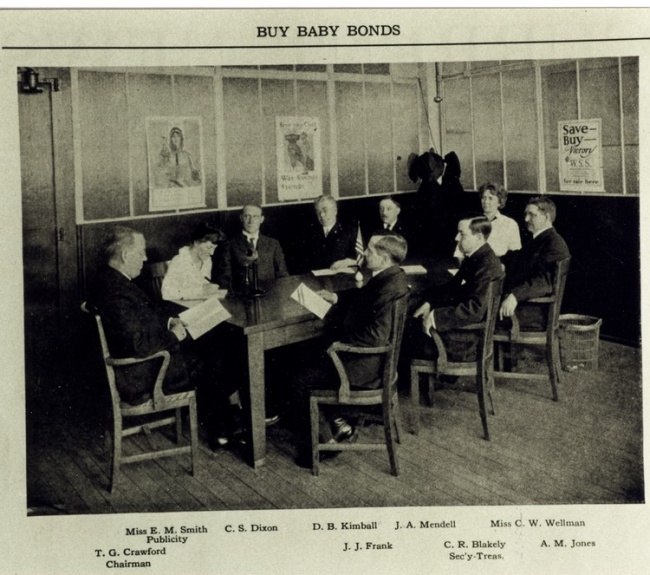

- The April, 1918 issue of the "Current News" was a special Liberty Loan issue. The Liberty Loan goal for the Pittsfield plant was set at $3,000,000.00. This was basically a loan to the U.S. Government to support U.S. involvement in World War I. War Savings Certificate Stamps (known as "Baby Bonds") were a means of making smaller contributions for those who could not afford to purchase a full Liberty Loan Bond all at once.

- In September, the Hon. Crawford Vaughan, ex-premier of South Australia, gave a "pep talk" to employees of the Pittsfield plant. At the conclusion of his speech, he said "I ask you to give three cheers for the Boys at the Front". Three cheers were given, followed by great applause and a rendition of "The Star-Spangled Banner" by the Works Band. In attendance were Pittsfield notables Miss Mira Hall, proprietress of Miss Hall's School in Pittsfield, and her niece, Miss Margaret Hall.

1919:

- The plant's telephone exchange was located on the top floor of Building 16.

- A new Machine Shop started operations in a section of Building 15. The original Machine Shop had been located at the north end of the Building 1-2-3 complex, an area known as the "hill" because it was on a higher level than the rest of the building due to the rise in the land beneath.

1920:

- A new auditorium in Building 16 was dedicated.

- G.E. sponsored an oriental musical revue at the Colonial Theatre called "Jappyland"!

- An article by a former New York City resident sang the praises of life in the Berkshires because living and working in "the City" meant a long commute every day and very high prices!

1921:

- A new Building 17 was built; this was to become the Winding Room where most of the large transformer windings were assembled for many years. Building 14 (originally built in 1909) had just been remodeled to become the new Tank Shop.

1922:

- A.B. Hendricks first produced a one million volt, three-phase arc in the High Voltage Lab.

1923:

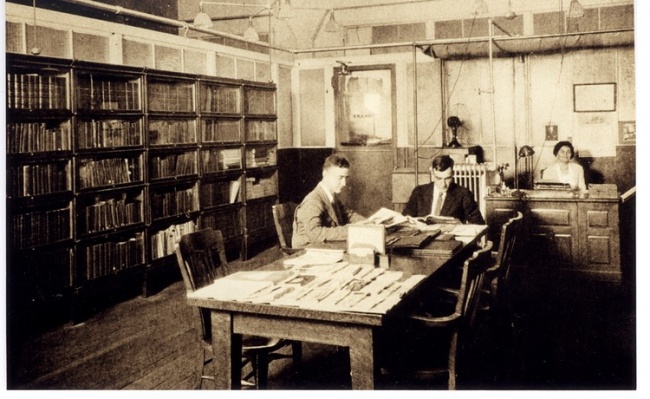

- The Stanley Library was created and housed in Building 16. This library combined a former Works Library in Building 42, a Laboratory library in Building 8, and one thousand volumes from William Stanley's personal library. The latter was a gift from Stanley's widow, Lila C. Stanley. The idea for the combined library was that of Cummings C. Chesney.

In 1948, the Stanley Library was moved back to Building 8 following the construction of a new floor in that building to vertically divide the "high bay" laboratory area there. General Manager Robert Paxton arranged for a $50,000 appropriation to accomplish this.

In 1966, the Library was moved to the newly-constructed Building 11. This building housed facilities for visitors, and General Manager Robert Gibson recognized that the presence of the Library would contribute to the impression that this was a top-notch research facility.

- According to Samuel Sass, venerable Librarian during the latter years of the Pittsfield G.E. operation, an interesting early use of a small building in the plant (Building 43A) came to light when he was looking for storage space for library books which were not often requested.

This building had been equipped with shower stalls and foot baths which, it turned out, dated from the days when lead oxide pellet lightning arresters were manufactured. The employees were required to shower and change clothes before going home so as not to take the lead dust with them!

This procedure had been instituted by a pioneer in the field of industrial toxicology, Dr. Alice Hamilton. She had been hired by Gerard Swope, president of General Electric, in 1923. In her capacity as Medical Consultant to the company, she recommended this and other procedural changes at the Pittsfield G.E. facility.

Dr. Hamilton died in 1970 and, as reported in the Berkshire Eagle of February 18, 1996, she has been honored by the United States Postal Service by the issuance of a stamp as part of its Great American series.

- A new Wood Shop went into operation, located in Building 7D.

- Dial telephones were installed in the plant.

- A 110-Kv double-circuit transmission line was placed in operation which connected the Pittsfield Electric Company with a hydroelectric plant at Turner's Falls, Mass. This line terminated at the Silver Lake Station of the Pittsfield company, adjacent to the G.E. Power House. It was about this time that the first ties were made between the G.E. power system and that of Pittsfield Electric. The 110-Kv transmission line is still in operation.

1924:

- The Stanley Club, a G.E. business-oriented social club, was organized in Pittsfield.

- The construction of Building 12X was announced. This was referred to as the "super-transformer building" for the assembly and testing of the largest transformers. It was built as an extension of the east side of the existing Building 12.

- Concrete reactors were being manufactured in Building 7B. These had been developed in 1910 and consisted of air-core reactor structures supported by a poured concrete framework. They were (and still are) used primarily as current-limiting devices in power systems.

- One million volt Test Sets, each using three cascade transformers, were built for the G.E. Works in Philadelphia, and for Commonwealth Electric, a mid-west utility.

- The first Load Ratio Control was built. This device allowed transformer voltage output to be adjusted under load. The concept had been developed by G.E. engineers.

Induction-type regulators were being manufactured in Building 19. This had been the case since 1912; from 1908 until 1912, they had been manufactured in Buildings 1-2-3, in the area known as the "hill" at the north end.

1925:

- The main Receiving Department for the plant was located in the basement of Building 42. This location allowed for direct access to the adjacent railroad tracks.

Fan motors were being manufactured in a part of Building 43(along Kellogg Street).

1926:

- The Wire Department was located on Columbus Avenue in Pittsfield.

- A new Laboratory facility was built; this was an addition to Building 8, known as "8-Ext".

1927:

- Capacitors were being manufactured in a part of Building 42.

- The Works Restaurant was now operating in a section of Building 43, known as "43B". A cafeteria for the "South Side" was operating in Building 27.

- The Power House was flooded to within one inch of the high voltage busses when Silver Lake overflowed!

- Edward Kopf graduated from the Pittsfield G.E. Apprentice Program, having joined it in 1923.

Mr. Kopf has quite a few interesting recol-lections of life in the Apprentice Program, as well as the Pittsfield plant in general.

The Apprentice Program operated out of part of Building 26, located near East Street. It utilized two classrooms plus a fully-equipped machine shop, as well as two full-time instructors.

Apprentices attended one two-hour class each working day. During the first year of the program, they learned how to operate every one of the machines in the shop. Then, they were sent to areas related to their particular line of interest: drafting, tool-making, pattern-making, maintenance, or engineering. There were both three and four year courses, and an entrance exam was mandatory.

Apprentices were able to obtain experience working in any of the different departments in the plant: principally Power Transformer, Distribution Transformer, Regulators, Load Ratio Control, Foundry, Tool Room, Lightning Arresters, and Bushings.

Starting pay on the four-year course was $9.60 per week for a 49-hour week. Exams were given every six months and, if passed, the Apprentice received a raise of two cents per hour!

Subjects taught during the course included Mechanical Drawing, Shop Math, Trigonometry, Mechanics, Mechanisms, Strength of Materials, Gear & Cam Design, Advanced Trig, Electricity (both AC & DC), Tool Design, and Machine Design.

Upon graduation from the course, each Apprentice received (personally) a large diploma from the Plant Manager. Also, in Ed Kopf's case, this diploma allowed him (in 1957) to obtain his Massachusetts License as a Professional Mechanical Engineer simply by taking a few night courses!

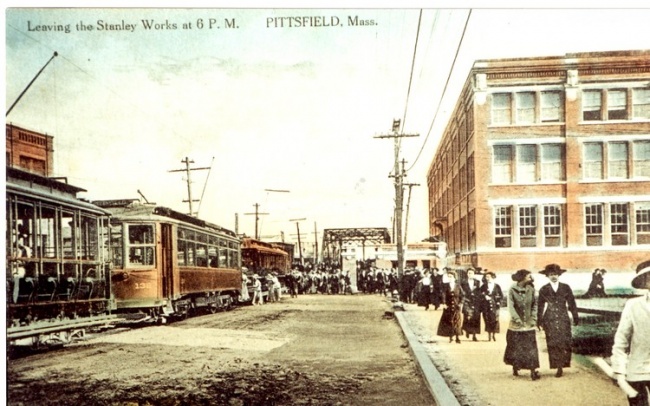

Other recollections of Mr. Kopf's include the fact that two small steam locomotives were used to haul materials around the plant in those days. Tracks ran up the hill from South Gate (at East Street), over the railroad, and out North Gate onto Woodlawn Avenue; then back into the plant at Building 17 and on to the Tank Shop (Building 14). In the winter, when ice and snow were on the tracks coming up from South Gate, men had to run ahead of the locomotive with buckets of sand to throw on the tracks for traction! Sometimes, with big loads, both locomotives had to be used running in tandem.

Also, during that era, the twelve to fifteen thousand employees in the Pittsfield plant received their pay in cash (no checks). Money was picked up at the First Agricultural Bank in Pittsfield and brought to the plant in a large safe mounted on a flatbed truck. This was a battery-operated truck, and only enough charge was put into the batteries to make the trip to the bank and back again! Armed guards from the plant accompanied the truck, and additional armed guards from the bank were on hand for the loading of the money into the truck.

The truck was driven into a freight elevator in Building 42 and taken up to the Payroll Department. Each department in the plant had a fold-up wire cage which was set up at a designated spot on pay day. The money was distributed to these various locations by other trucks. At each stop, the money and a payroll clerk were left in the cage. Pay envelopes were arranged by clock number, and it took only ten or fifteen minutes in each department to distribute all of the pay.

1928:

- An article reported that the Pittsfield Works employed 7000 people, covered 153 acres, and produced:

"transformers, voltage regulators, cut-outs, current limiting reactors, heating devices, lightning arresters, capacitors, and single-phase motors."

- L.V. Bewley, world-renowned expert in surge phenomena and lightning-related disturbances on high voltage transmission lines, came to work at the Pittsfield plant from Schenectady General Electric.

- The first oscillogram of natural lightning was taken by personnel of the High Voltage Engineering Laboratory at Lake Wallenpaupack, Pa.

- A major civic improvement in the vicinity of the Pittsfield plant was the paving of East Street!

- An article reported that an oil-filled transformer had burned up after seven years in service. However, inspection showed that the mid-western utility customer had never filled it with oil, and that the instruction manual was still hanging inside the tank!!

(This is an indication of how equipment of this era was over-designed; the unit probably burned up because the load had slowly increased over the years.)

1929:

- A new Building 34 was built, on the South Side of the plant near Silver Lake, which replaced an earlier building used mainly as a Pattern Shop for the adjacent Foundry in Building 33. The new Building 34 is still there.

- Nearby Building 36 housed the Molded Insulation Department.

- Silver Lake Boulevard was constructed around Silver Lake.

1930:

- Thyrite (G.E. trademark) was developed. This is a non-linear resistance material composed of a silicon carbide compound. It is used in lightning arrester and surge suppressor type devices to "clamp" over-voltages, but prevent the normal power system voltage from causing a current flow through it.

- The first commercial Impulse Test was performed on a transformer. This test simulates the effect of lightning-related surges which the transformer may be subjected to in service and demonstrates that the transformer insulation will withstand such mistreatment.

- Giuseppe Faccioli retires due to ill health.

- Cummings C. Chesney retires.

- Building 62 is built south of East Street. This functioned as the Gas Plant, producing various types of bottled gas for use in production processes.

- A new Building 14 is under construction to replace the earlier Tank Shop. This was one of the first welded steel buildings in the country; prior to this, steel buildings were of riveted construction.

- The five-day work week was introduced, giving employees a full weekend off.

- Safety shoes were introduced.

1931:

- F.W. Peek, Jr. becomes the Chief Engineer of the Pittsfield Works.

- The new Tank Shop (Building 14) is placed in operation; it includes a cafeteria. An Open House is held in June.

- Four network transformers are built for the Pittsfield Electric Company, and installed on West Street, Elm Street, Worthington St., and Francis Avenue in Pittsfield.

The next chapter contains biographies of several of the notable professionals associated with the Pittsfield, plant over the years.

Mrs. Irma Giegold, of Pittsfield, recalls that her father, Arthur Palme, was a friend and co-worker of all these gentlemen. Mr. Palme worked as an engineer from 1913 until his death in 1949. In particular, Mr. Palme was hired by Works Manager Cummings C. Chesney in spite of the fact that, at the time, Mr. Palme could not speak a word of English!, In fact, during World War I, he was restricted to his desk, the men's room, and the Works Restaurant because he was considered to be an "alien enemy". When he became a U.S. citizen in 1919, his co-workers decorated his desk with an American flag and threw a party. He was then finally given full access to "the shop"!

Eventually, Mr. Palme received several patents. He was also well received by the shop workmen because. he spoke their language, which was predominantly Italian at the time. During Prohibition, he was often favored with gifts of homemade wine!

Mrs. Giegold later became a Pittsfield G.E. employee herself. Once, her father "spirited" her into the High Voltage Laboratory to see a demonstration of artificial lightning which was being staged especially for then Governor of Massachusetts, James Curley.

Chapter 4: Biographies

Guglielmo C. Camilli

Guglielmo Camilli was a native of Rome, Italy; he received his engineering degree from the Royal Polytechnic School of Turin in 1922. In 1926, he began his career with General Electric as a Development Engineer in Pittsfield.

In 1956, he was named Supervisor of Power Transformer Advance Product Engineering. By 1958, he had received a total of fifty-five patents, more than anyone else in the General Electric Company at the time. He was twice the recipient of the Coffin Award, the highest employee honor bestowed by General Electric. He was the author of a book on the subject of transformer engineering, and authored many technical papers throughout his career.

Camilli was an avid amateur astronomer. He ground his own lenses and built his own telescopes. He was a member of the volunteer Pittsfield G.E. Speakers Bureau; as such, he presented a very popular talk around the country which was called "A Trip through the Universe". He predicted that the United States would reach the moon by 1967 (not far off!). He also used his immense knowledge of transformer insulation structures and cooling methods to design a "transformer for use on the moon" in 1955! He operated his own personal observatory at his home on East New Lenox Road in Pittsfield.

In 1928, he constructed a home-brew television set for his own use. This was the first television of any type which was seen in Pittsfield.

Cummings C. Chesney

C.C. Chesney, a native of Pennsylvania, was born in 1863. Following his graduation from Pennsylvania State College in 1885, he taught mathematics and chemistry until becoming associated with William Stanley in 1888, in Great Barrington, Mass., as a chemist and engineer.

He followed Stanley to the United States Electric Lighting Company in Newark, New Jersey (a subsidiary of the Westinghouse Company) in 1889. He then became associated with the Stanley Electrical Manufacturing Company in Pittsfield as an electrical engineer in 1891. He was the "C" in the S.K.C. system marketed by Stanley.

In 1903, when the Stanley Company became a subsidiary of General Electric, Chesney was advanced to the position of Vice-President and Chief Engineer. In 1907, when the company became the Pittsfield Works of General Electric, Chesney was named Works Manager. He continued in this capacity until 1927 when he was named a vice-president of the General Electric Company.

While with Stanley, he personally supervised the design of S.K.C. equipment, including the first revolving field type of alternator used in this country.

Chesney was very active in local business activities as well as civic affairs. He was active in the Boys' Club of Pittsfield, and was a member of the Chamber of Commerce there.

In 1921, he received the Edison Medal from the American Institute of Electrical Engineers, and he served as President of that organization from 1926 to 1927. The Edison Medal is the highest award given to an electrical engineer, and is for meritorious achievements in electrical science, engineering and art.

Cummings Chesney retired in 1930 and died in 1947. He was survived by his widow, Elizabeth, four daughters, a son, and eleven grandchildren.

Giuseppe Faccioli

Giuseppe Faccioli was born in Rome, Italy in 1877 and graduated with high honors from the Institute of Technology in Milan in 1899 as a mechanical and electrical engineer. He came to the United States in 1902 and obtained a position with the New York Edison Company (the ancestor of Consolidated Edison in New York City). One year later, however, he transferred to the employ of the Interborough Rapid Transit Company, the builders of the first subway system (the IRT) in New York City.

Then, in 1904, he went to work for the Crocker-Wheeler Company in Ampere, New Jersey (near East Orange). Crocker-Wheeler had been building rotating electrical machines for the Stanley Company and, as a result, he came into contact with William Stanley. This led to his joining Stanley in Great Barrington (by this time, the Stanley Company in Pittsfield was a subsidiary of General Electric, and Stanley himself had gone back to Great Barrington to engage in other ventures).

In 1908, Mr. Faccioli transferred to the Engineering Department of the Pittsfield Works of General Electric. In 1911, he was appointed Assistant Chief Engineer and, in 1914, he became Chief Electrical Engineer of the Pittsfield Works. In this capacity, over the years, he became intensely interested in high voltage power transmission work, and contributed heavily to the development of high voltage transformers and lightning arresters.

He was very active in the American Institute of Electrical Engineers and was the author of highly technical papers on subjects such as electrical transients.

Mr. Faccioli retired in 1930; by that time, he had been confined to a wheelchair for many years. A presentation in honor of his retirement was made at his home on East Housatonic Street in Pittsfield; this house still stands today.

Allan Barringer Hendricks, Jr.

Mr. Hendricks was born in 1874 in Duchess County, New York State. In 1900, he completed a special three-year course at the Lawrence Scientific School of Harvard University. In September of that year, he entered the employ of the Stanley Electrical Manufacturing Company in Pittsfield where he worked on the assembly of switchboards and in instrument test.

In 1901, he moved to the Morningside Plant of the Stanley Company in Pittsfield and spent a year in generator and transformer test. He then began to specialize in the areas of insulating materials, line insulator design, and the measurement of high voltage line losses. Between 1905 and 1911, he organized the testing laboratory, acting in the capacity of engineer of insulating material development.

In 1906, he designed and built the first transformer devoted to the testing of insulation; it was capable of producing voltages up to 150,000 volts. In 1911, he transferred to the Transformer Engineering Department as a development engineer in the design of high voltage transformers and allied devices. Under his guidance, all of the transformers used in high voltage testing were designed, providing up to 1,000,000 volts three-phase and 1,500,000 volts to ground (single-phase).

In 1922, he devised the 1,000,000 volt three-phase arc which remained a mainstay of public demonstrations for the next fifty years or so.

He was also involved in the development of equipment such as high current testing transformers, cable testing apparatus, x-ray transformers, high frequency transformers, power and filament transformers for vacuum tube rectifiers, and air-blast type power transformers for use by the Interborough Rapid Transit Company of New York City (builders of the first subway system there).

In later years, he was also intimately involved with the design of impulse generators for laboratory testing with simulated lightning surges.

Dr. Karl B. McEachron

Dr. McEachron was born in Hoosick Falls, New York in 1890. He graduated from Ohio Northern University in 1913 with both E.E. and M.E. degrees. That same year he joined the General Electric Company as a student engineer on the test course. In 1914, he returned to Ohio Northern as an instructor in electrical engineering. In 1918, he became an instructor and research associate at the Engineering Experiment Station of Purdue University where he received an M.S. degree in Electrical Engineering.

In 1922, he returned to G.E. to take charge of the research and development section of Lightning Arrester Engineering Development in Pittsfield. In 1933, he was appointed engineer in charge of the High Voltage Engineering Laboratory. In 1945, he was appointed Assistant Works Engineer. In 1947, he was named the Assistant Manager of Engineering of the Transformer and Allied Products Division. In 1949, he was appointed Manager of the TAP Division.

He received the appointment of Manager, Laboratory-Engineering Department in 1952, and, in 1953, was named as the Consultant of Professional Employee Relations for all technical employees in the Engineering Services Division of the General Electric Company.

He originated and supervised the lightning investigation at the Empire State Building which yielded a vast amount of valuable data on natural lightning. Also, under his direction, 10,000,000 volt discharges were produced by impulse generators at the 1939 New York World's Fair, and the new High Voltage Laboratory building (Building 9) was opened in Pittsfield in 1949.

Dr. McEachron was a recognized authority on lightning, world-wide. He was often called upon to testify in cases of lightning-caused injuries and damage. In 1940, he coauthored the book "Playing with Lightning", and, in 1948, he wrote the article "Lightning and Lightning Protection" for inclusion in the Encyclopedia Britannica. He was also the author of many technical papers on the subject of lightning and related topics.

Walter Sherman Moody

W.S. Moody was born in Chelsea, Mass. in 1864. In 1887, he graduated from M.I.T. with a degree in Electrical Engineering. He then became an instructor in physics and electrical engineering at M.I.T.

In 1888, he became an assistant engineer at the Thomson Electric Welding Company in Lynn, Mass. This company was started by Elihu Thomson of the Thomson-Houston Electric Company (Thomson was the inventor of the electric welding process). In 1892, The Thomson-Houston Company was merged with the Edison General Electric Company to form the present General Electric.

Mr. Moody then joined the Thomson-Houston Company in 1892, the year of the merger. After General Electric was formed, he became the Chief Engineer of the Lynn Transformer Works of General Electric. In 1897, he moved to Schenectady and assumed the same position at that plant.

In 1908, after the Stanley Company had become the Pittsfield Works of General Electric, Mr. Moody moved here to continue his career. He came to be known as a pioneer in transformer design, and he retired as a Consulting Engineer in 1931.

Among his accomplishments included the design and development of the extremely successful Type 'H' distribution transformer, a basic design for air-blast type transformers, and, perhaps most notably, the development of a practical process for rolling silicon steel to be used for the construction of low loss transformer cores.

Mr. Moody died at home in Pittsfield in 1938, at the age of seventy-four.

K. K. Paluev

Konstantin K. Paluev was born in Russia in 1894 and was educated as an engineer at the Polytechnic Institute of Peter the Great in Petrograd. He came to this country in 1916 as a representative of the Czarist government to inspect United States ammunition bound for Russia. He often declared that the Russian Revolution "set him free" in this country.

He came to the Pittsfield G.E. plant in 1919, and his contributions to the design of transformers were enormous.

Paluev was responsible for the development of the "non-resonating" winding configuration in transformers. This was a way of designing windings with electrical_ characteristics such that they would be much less susceptible to the very high surge voltages produced by lightning strokes. He accomplished this in the 1920's, and it was the only way in which transformers were able to be designed for operation at voltages as high as the upper voltage limit at that time, which was 230-Kv.

In 1930, he played a leading role in the development of forced-oil cooling for large power transformers. This development was to be of great advantage in the design of large, high power transformers needed for various aspects of the war effort during World War II, as well as the large capacity transformers needed during the post-war period.

He was noted for his belief in the doctrine of "collective genius". This concept dealt with the ability of a group of people, in a free society, to be able to accomplish far, more than their individual talents would indicate was possible. He considered this to be the prime reason for American productivity and inventiveness.

Paluev died in 1958, at the age of sixty-four, in Pittsfield General Hospital a month after having received a severe electrical shock.

Frank W. Peek, Jr.

F.W. Peek was born in California in 1881. He graduated from Leland Stanford University in 1905 with a Bachelor of Arts degree, and from Union College in Schenectady with a Master's Degree in Electrical Engineering in 1911. He entered the employ of the General Electric Company in 1905 as a test man in Schenectady. A year later, he was placed in charge of special testing in engineering research.

Mr. Peek became interested in high voltage research about 1906, when this was a very new subject. Funding was hard to obtain, so he set up a laboratory in an old boxcar in a remote corner of the Schenectady G.E. plant. Periodically, he would discuss the results of his work with the famous G.E. scientist, Dr. C.P. Steinmetz. In 1909, he was one of the first young engineers to join the newly-formed Consulting Engineering Department of the G.E. Company, under Dr. Steinmetz.

In 1916, Mr. Peek was transferred to Pittsfield where high voltage research work was underway. Soon after Dr. Steinmetz built his first lightning generator in Schenectady, Mr. Peek was building similar machines in Pittsfield, but at ever increasing voltages.

In 1931, Mr. Peek was named Chief Engineer of the Pittsfield Works, succeeding Giuseppe Faccioli who had recently retired due to ill health.

Very unfortunately, however, Mr. Peek was killed in an automobile accident while travelling on vacation in Canada in 1933; he was fifty-two years old.

Chapter 5: The Depression and War Years

There was not much specific mention of the Depression in the Pittsfield G.E. News during this period of time. However, in 1930, G.E. President Gerard Swope instituted an Emergency Unemployment Fund. This was funded by a compulsory one percent contribution from all employees' salaries, and was matched by G.E. It was started in response to the "present unemployment emergency".

In 1934, publication of the weekly newspaper-style Pittsfield G.E. News began, and continued in that format through the plant closing in 1987.

1934:

- Both Pathe and Movietone News made newsreels of a new high current generator located in Building 12A; this device was built in order to study the destructive effects of current in natural lightning strokes (up to 250,000 amperes!).

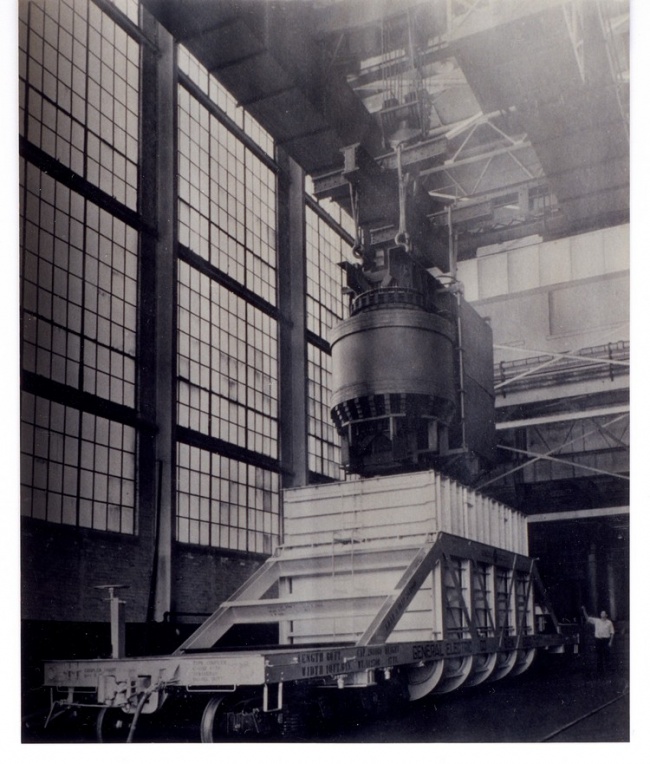

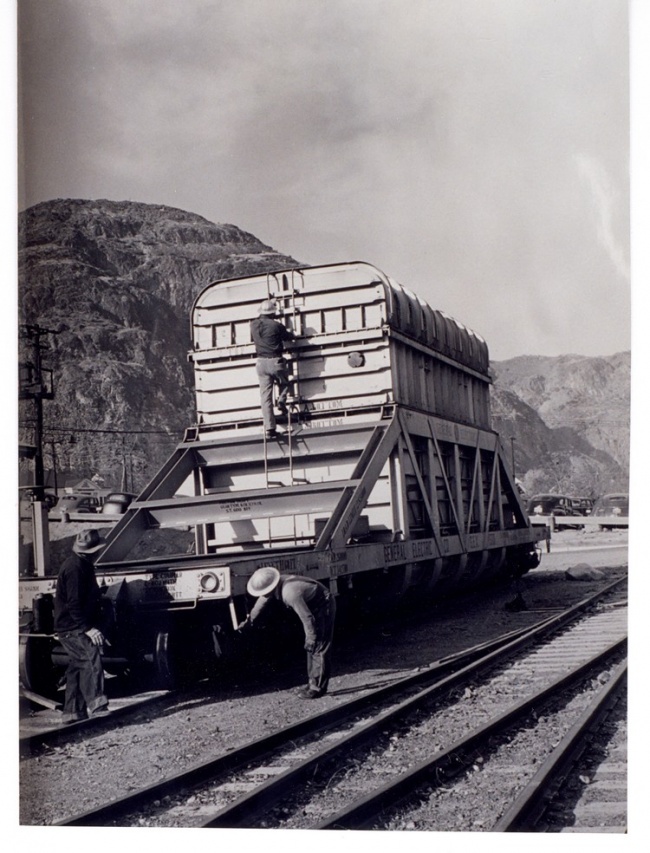

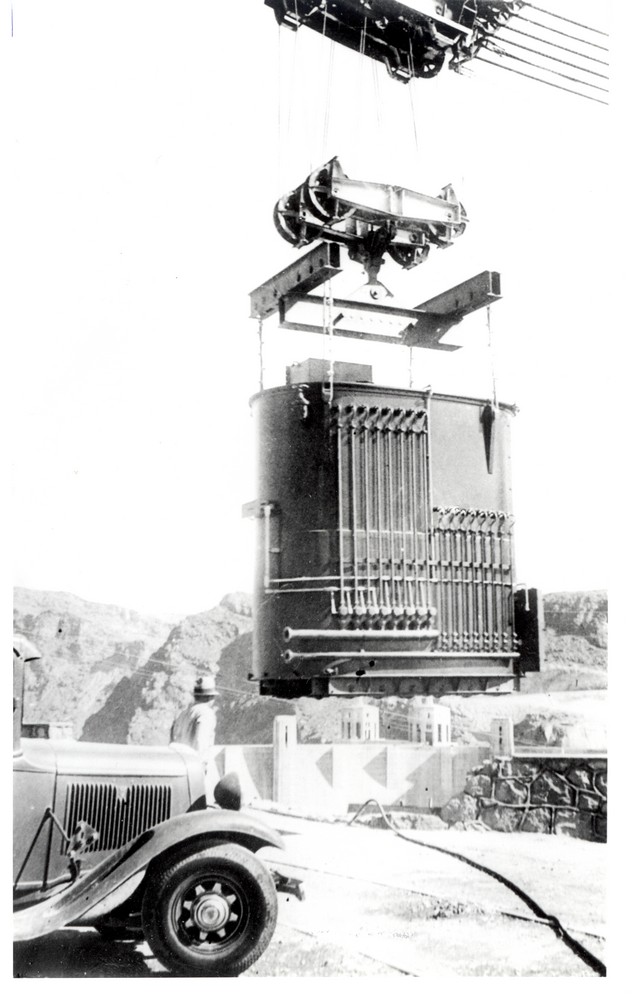

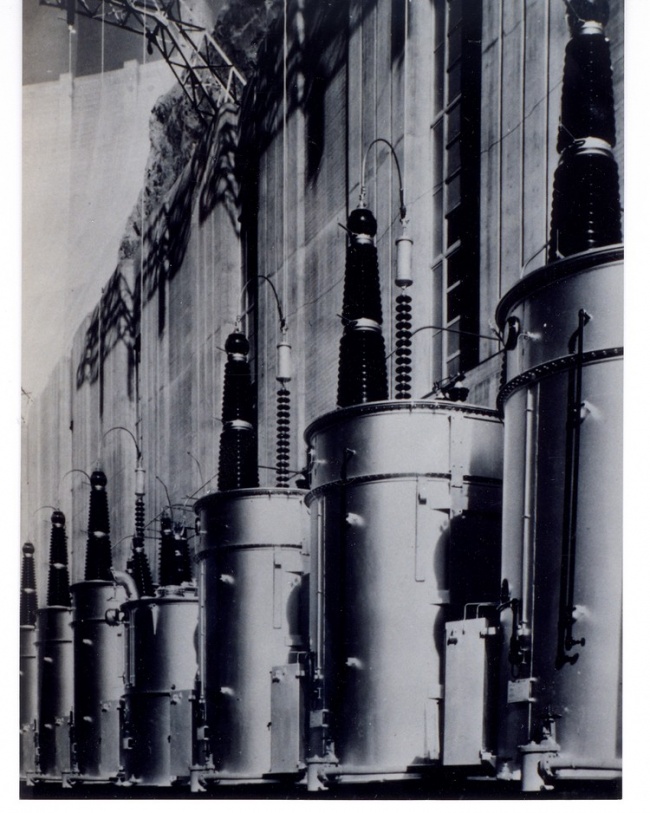

- Eleven transformers were built for the new Boulder Dam (later, Hoover Dam) powerhouse on the Colorado River between Arizona and Nevada. This was a one million dollar order!

- One hundred and fifty boilers for G.E. oil furnaces were built in the Tank Shop for Mount Holyoke College in South Hadley, Mass.

- Lightning tests were being performed on cable buried at the "old Allen Farms" in Pittsfield. These tests were conducted by L.V. Bewley, noted expert on lightning-related transients from Schenectady G.E., and Julius Hagenguth of the Pittsfield High Voltage Laboratory. 41

1935:

- A new Visitors Reception Room was opened in Building 42.

- A lightning observatory was built on the roof of Building 43.

- The first Boulder Dam transformer was shipped.

1936:

- A Relief Loan Plan for needy workers was approved by plant employees.

- A new auditorium was opened in Building 16.

- The Stanley Club presented a concert by the Pittsfield Symphony Orchestra at the Masonic Temple in Pittsfield.

- Coils for a new Cyclotron ("atom-smasher") at the University of Rochester were being built in the Pittsfield plant.

- The Golden Jubilee of the Stanley transformer of 1886 was celebrated with festivities at Pittsfield High School.

- An early version of a forced-air cooled type of transformer was built for the Consolidated Gas and Electric Company of Baltimore, MD_ An external blower was used, rather than fans as became the later standard practice. This was an oil-filled transformer; "air-blast" dry type transformers had been in use for many years by this time.

- A Test Man in Distribution Transformer Test was electrocuted from accidental contact with a 7200-volt circuit in Building 26.

- The Stanley Club moved into new quarters at 54 Wendell Avenue in Pittsfield. The main house was known as the Hinsdale Mansion, and a carriage barn on the premises was converted into an auditorium. The purchase price of the property was $16,500, and the plan was to pay for it by raising the annual dues from $8.00 to $12.00! Eventually, the main house was sold and the carriage barn became the Stanley Club.

- An unfortunate record was set by the occurrence of seventy-five lost-time accidents for the year.

Pyranol

Also, in 1936, thirty Pyranol network transformers were built for the New York and Queens Electric Light and Power Company in New York City.

The vast majority of transformers built in Pittsfield were filled with mineral oil (known as Transil or "10C" oil) which acted as an insulating fluid as well as a heat-conducting fluid. However, as with other petroleum products, it suffered from the disadvantage of being flammable.

By 1932, the Monsanto Chemical Company, in conjunction with F.M. Clark of General Electric, had developed a synthetic fluid which had insulating and heat conducting properties similar to mineral oil, but was not flammable. Thus, it was put into use for transformers which had to be installed in locations where fire would have devastating consequences; these included tall buildings and under-street vaults in large cities, as well as on electrically-powered passenger trains.

The chemical mixture was known as Pyranol (a G.E. trademark) and its two constituent parts, a resin and a solvent, were shipped in separate railroad tank cars to the Pittsfield plant. The mixing of these two components to form the Pyranol fluid took place in Building 12G. This building was located to the east of Building 12Y, and was razed during the construction of Building 100, in 1966.

Pyranol contained a large proportion of "PCB's", or poly-chlorinated biphenyls. By 1977, it had been determined that PCB's in high concentrations could cause the development of cancers in laboratory animals. Thus, the use of Pyranol was discontinued. As of this date, however, a definite link between PCB's and human cancer has yet to be proven.

While Pyranol was in use in the Pittsfield plant, great care was taken to insure that it would not be accidently mixed with the "10C" oil which was used in the majority of transformers built. This was because it had been determined that Pyranol had a very destructive effect on some of the insulating materials which were used in oil-filled transformers; particularly the glues and other binders used to hold together paper-type insulation structures.

Also, while Pyranol was a good insulating fluid, it had been found that it was not capable of insulating against voltages higher than about 200 kilovolts. Since large transformers were often designed to operate at voltage levels significantly higher than this, Pyranol was of no use for these designs. Accordingly, Pyranol was kept completely out of the new transformer assembly building (Building 100) when it was put into operation in 1968, since the largest and highest voltage transformers were built there.

1937:

- The Pittsfield G.E. Plastics Operation moved from a location on East Street to "the old porcelain plant" on Ceramic Avenue.

- The Employees' Store moved into new quarters in Building 42.

- Elihu Thomson died at the age of eighty-four. He was the guiding force behind the Thomson-Houston Company of Lynn, Mass, which was combined with the Edison General Electric Company in 1892 to form the present General Electric Company. The Thomson-Houston plant in Lynn eventually became the Lynn Works of G.E.

- Pyranol railway transformers. were being built for both the Pennsylvania Railroad and the New York, New Haven and Hartford Railroad.

- Cyclotron coils were being built for Harvard University.

- Last year's record for lost-time accidents was broken: eighty-one this year!

1938:

- The largest transformer built to date is a second forced air (called "forced draft") cooled unit for Consolidated Gas and Electric of Baltimore. It weighed 215 tons, and was rated at 53,333 Kva and 115-Kv. It was to be used as part of an intertie between Washington, D.C. and Baltimore. -

- A wound-type core, called Spiracore (G.E. trademark), was developed for use in small distribution transformers.

L.V. Bewley, noted G.E. theoretician, was to teach a course on "Symmetrical Components", a method of calculating three-phase circuit behavior.

- A G.E. ad brags about the fact that the United States, with only 1/15 of the world's population, uses 1/3 of the world's electric power and has 3/4 of all of the automobiles in the world!

1939:

- A photo in the G.E. News shows the impulse generator used for the G.E. exhibit at the 1939 New York World's Fair; this generator was used to produce artificial lightning discharges in Steinmetz Hall at the Fair.

- Excursion trains were being run from Pittsfield to the World's Fair in New York City.

1940:

- Employee Badges were first introduced. (This may have had something to do with tightened plant security during the "war years".)

- A new Display Room for transformer products Was opened in Building 16.

- The plant Photo Department was in Building 10. An addition to Building 14 (the Tank Shop) was begun.

- October 5 was "G.E. Day" at the World's Fair!

- A building at One Plastics Avenue was begun for the production of Textolite, a trademark G.E. plastics material. Also, just across the street, the "National Defense Building" was begun; this was the beginning of what would become the Pittsfield G.E. Naval Ordnance Department.

- The Capitol Theatre in Pittsfield was pre- viewing the new film "Edison, The Man".

World War II

In the interest of national security, nothing was published in the Pittsfield G.E. News regarding any involvement in technical activities related to the war effort, on the part of the Pittsfield G.E. plant.

However, Harry Mason, a former Design Engineer in the Pittsfield transformer operation, has some interesting recollections of this era. Most notably, he was involved in a special project which included the design and manufacture of a large quantity of special transformers for use in the Manhattan Project, which led to the development of the atomic bomb.

These were rectifier transformers which were shipped to Oak Ridge, Tennessee. They were used in conjunction with rectifiers to produce direct current needed to accelerate uranium ions through a strong magnetic field. This would then separate fissionable U235 from U238.

In order to assemble these units, a special enclosure was built at the north end of Building 3 (inside of the building itself). It had only one entrance and armed guards were stationed both inside and out at all times! The rectifiers themselves utilized vacuum tubes which were eighteen inches in diameter and thirty-six inches long; they were water-cooled. One such rectifier unit was completed per week.

Harry remembers an airplane trip to Berkeley, California (eighteen hours in a DC-3!) where the famous physicist, Dr. E.O. Lawrence, was using some prototype transformers in uranium ion separation experiments at the University of California. Harry later spent six weeks at Oak Ridge during the initial use of the pro-duction transformers there.

As an interesting aside to this, George Sauer, formerly of Power Transformer Engineering, remembers that the first of the Oak Ridge units into Test suffered a flashover of one of its porcelain bushings. This created somewhat of a crisis due to the impending need for these transformers; as a result, a great deal of "rush" bushing development work was created for the G.E. High Voltage Laboratory in the Pittsfield plant. This, in turn, created lots of draft deferments for the men who were involved in this work!

In addition, Ed Kopf (see "1927" in Chapter 3) recalls an incident in which a worker from this project was being much too loose-lipped on his way to lunch one day. While walking to a restaurant on Woodlawn Avenue near the plant, his conversation was overheard by a Government man walking behind him. He was stopped and was taken to the Chief of Plant Protection who proceeded to deliver a very strong admonition to watch his mouth from then on! Apparently, he had guessed at the intended use for the power supplies which he was working on, as being part of the atomic bomb development work. According to Ed, very few people ever saw the complete drawings for these power supplies; copies of them were cut up and the individual sections were distributed to the particular workers who needed them. Each section was given a serial number and was signed for when taken out. Thus, it had to be returned at the end of the shift. The drawing sections not in use at any given time were kept locked in the office safe.

In the realm of miscellany, Harry Mason recalls that the older engineers during this time had their own personal spittoons on the floor next to their desks! They were filled with water and would be emptied every night by the janitor.

He also recalls that there was an abundance of foreign born engineers working in the Pittsfield plant at this time. In particular:

Aram Boyajian (Armenian)

L.R. Bronlund (Swedish)

Guglielmo Camilli (Italian)

Alexis Garin (Russian)

K.K. Paluev (Russian)

Max Sauter (Swiss)

A.E.F. Smith (Bermudan)

Magnus Unger (Swedish)

1941:

- A new G.E.A.A. facility opened on Crane Avenue in Pittsfield.

- An expansion of the Power House was begun.

- The last steam locomotive switcher used in the plant was scrapped; a new diesel switcher was purchased from the Erie, Pa. G.E. plant.

- A new addition was made to the "Foundry. Building" (Building 33 on the South Side).

- A new vacuum tank, used to "treat" transformer core and coil units to remove moisture, was installed in Building 12-Ext.

- A rush transformer order was received from ALCOA (Aluminum Company of America).

- The Pittsfield plant guards were armed!

The Story of the Silver Transformers

In 1942, due to a critical shortage of copper, twelve transformers were built at the Pittsfield plant which had silver windings!

These were 12,500 Kva, 138-kv units needed for an aluminum reduction plant at Maspeth, Long Island which was operated by ALCOA. The silver came from the United States Treasury vaults at West Point, NY. Seventy-five tons of silver, valued at almost one million dollars in 1942 currency, were used.

The silver was, and remained, the property of the U.S. Treasury. Because of its high value, extraordinary precautions were taken during its transportation and handling. Each 25-ton railroad carload of silver travelled to Pittsfield escorted by U.S. Treasury guards armed with machine guns. Other Treasury guards were present during all fabricating operations, and all scraps of silver had to be accounted for.

Since it was desired to eventually reclaim the silver, a plan had been developed providing for later disassembly of the transformers to replace the silver with copper.

The transformers were built on a rush basis, passed all tests, were shipped on schedule, and remained in service for a year and a half.

1942:

- An extension was begun at the east end of Building 14 (the Tank Shop).

- A list of names was published in the Pittsfield G.E. News for the purpose of car pooling. This was noted as being the result of "a reduction in gasoline allotments, in this area". Car pooling was encouraged, but was in no way compulsory.

1943:

- Stators for large ship propulsion motors were being built at the Pittsfield plant.

- The Amplidyne was developed by E.F.W. Alexanderson of Schenectady G.E. Alexanderson had been instrumental in the development of large high frequency alternators for "wireless" communication before World War I. The Amplidyne D.C. control generator eventually found extensive use in the precise control of voltage from generators used to test transformers in the Pittsfield plant.

- A play review of “The Eve of St. Mark" was printed in the Pittsfield G.E. News. This was performed by the Town Players of Pittsfield, a local amateur group, at the auditorium in the Berkshire Museum on South Street in Pittsfield. George Sauer, then a transformer design engineer, was included in the cast.

1944:

- An extension to Building 63, located south of East Street, was begun.

- The G.E. facility on Columbus Avenue in Pittsfield was referred to as "Building 81".

1945:

- Sam Sass was appointed Librarian for the William Stanley Library in the plant; Sam served in this capacity until 1976.

- Radar modulation transformers were being built in Building 26.

- A new Building 12B was constructed; it was to be used for short-circuit testing of coils and other transformer components.

- The first plant Open House in nineteen years was held.

- A second extension on the east end of the Tank Shop (Building 14) is begun.

- High voltage bushings are now being built in Building 17.

- The Columbus Avenue plant is now the Industrial Heating Division.

1947:

- An addition to Building 15 is underway.

- The High Voltage Laboratory (Building 9) is under construction.

- Cummings C. Chesney died.

- The old Power House smokestack was torn down.

- Thomas Scorpa was electrocuted in the Test operation associated with the manufacture of capacitors.

1948:

- The Stanley Library moved to new quarters in Building 8 (see "1923").

- A new Power House smokestack was built.

- The world's largest overhead rolling door was installed in the rear of Building 9.

- Cyclotron coils were being built for Harvard University.

1949:

- Building 9B was under construction.

- The Building 16 auditorium was renovated.

- Another Open House was held.

- The High Voltage Laboratory opened.