Oral-History:Humboldt W. Leverenz: Difference between revisions

m (corrected interview number) |

|||

| Line 21: | Line 21: | ||

HUMBOLDT W. LEVERENZ: An Interview Conducted by Mark Heyer, IEEE History Center, July 15, 1975 | HUMBOLDT W. LEVERENZ: An Interview Conducted by Mark Heyer, IEEE History Center, July 15, 1975 | ||

Interview # | Interview # 027 for the IEEE History Center, The Institute of Electrical and Electronics Engineers, Inc. | ||

== Copyright Statement == | == Copyright Statement == | ||

Revision as of 19:10, 17 September 2009

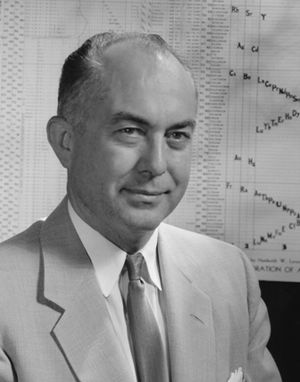

About Humboldt W. Leverenz

Humboldt W. Leverenz, a specialist in materials used in electrical technologies, graduated from Stanford University in 1930 with a degree in chemistry. He spent a year at the University of Muenster before joining RCA at Camden in 1931. His initial research with RCA was on luminescent materials under the direction of Vladimir Zworykin. He received the Franklin Institute Brown Medal in 1954 for his contributions to the development of the fluorescent lamp.

The interview begins with a discussion of Leverenz's work for RCA during the Depression. The main focus of his research at this time was developing luminescent materials for development of an all-electronic television. Leverenz's development of zinc beryllium silicate manganese was a major contribution to the development of practical fluorescent lamps. He eventually shifted his research to sulfur-dominated materials. He also contributed to improving secondary electron emitters, as well as working on thermionic emitter coatings and enamels.

In 1938, Leverenz transferred to RCA's Harrison, New Jersey plant where he designed both the acid process for phosphor production and the production design for the Harrison plant. Leverenz also designed RCA's Lancaster, Pennsylvania phosphor plant. The interview continues with a discussion of Leverenz's work at the RCA Princeton lab, including his work with ferrites and his contributions to the development of the orthicon and kinescope. The interview concludes with remarks by Leverenz concerning creativity, consumer demands, and future developments in television and the video disk.

About the Interview

HUMBOLDT W. LEVERENZ: An Interview Conducted by Mark Heyer, IEEE History Center, July 15, 1975

Interview # 027 for the IEEE History Center, The Institute of Electrical and Electronics Engineers, Inc.

Copyright Statement

This manuscript is being made available for research purposes only. All literary rights in the manuscript, including the right to publish, are reserved to the IEEE History Center. No part of the manuscript may be quoted for publication without the written permission of the Director of IEEE History Center.

Request for permission to quote for publication should be addressed to the IEEE History Center Oral History Program, 39 Union Street, New Brunswick, NJ 08901-8538 USA. It should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Humboldt W. Leverenz, an oral history conducted in 1975 by Mark Heyer, IEEE History Center, New Brunswick, NJ, USA.

Interview

Interview: Humboldt W. Leverenz Interviewer: Mark Heyer Date: July 15, 1975

Education and Decision to Work at RCA

Leverenz:

This is Humboldt Leverenz, commonly called "Lefty." Going back to the beginning, I grew up on what we euphemistically called a "ranch" in California, which was really mostly an almond orchard — 50 acres, a small spread. This was back starting back about 1915. I was very impressed as a young fellow after the sun went down seeing the little glow of light here and only occasionally there, way off in the distance, of some other farmhouse. In those days we didn't have electric lights; we mostly used candles and kerosene lanterns. Light was a rather rare sight out there. I went to Stanford, majored in chemistry, graduated in 1930, got a fellowship, and spent a year at the University of Muenster in Westphalia in Germany. I tended more towards physics, math, and some chemistry. On my return to this country, on the Eastern side, a former fraternity brother of mine at Stanford, Loren F. Jones, who was an RCA employee and an ex-General Electric employee, persuaded me to come to RCA Camden for an interview. I talked with several people. I already had an offer before I left for Germany to join the Bell Telephone Research Laboratory, so I was mightily interested in that, too, but this was 1931 and the Depression was in full swing. I remember being influenced quite strongly by a B.R. Cummings, who was one of the RCA engineering officials, who told me that he had worked with Bell Telephone Laboratories. He said, "It's a wonderful place and I sure can't knock it." I don't think he used those terms, but that was the general sensation.

But he said, "There is one big difference between working for Bell Telephone Laboratories and working for RCA and that's this: if you work for Bell Telephone Laboratory, you go in and you'll be assigned to something, let's say slow-acting relays," that's what he actually said, "and when you're 65 and retire, you'll probably be the world's outstanding authority on slow-acting relays, but you won't have had much opportunity to work on other things. Now RCA is very different. We're young. We're not as well established. We don't have the manpower or the equipment, and we require people to work on a lot of different things. If you find that exciting, RCA is the place for you." Among the other people who interviewed me was my first boss, Dr. Vladimir Zworykin. After some talk, he nodded his approval and asked if I would work on fluorescence and phosphorescence, and I said, "Yes." I went back to New York City, where I was staying with some friends of my parents, went to the public library and looked those words up because I didn't know what they meant. Fluorescence I found out is "light emitted from a material while it's being excited by ultraviolet or alpha particles or electrons, with no glow after the excitation stops" and phosphorescence is "luminescence not only during the excitation but after the excitation has stopped, afterglow." As I mentioned, this was during the Depression, and I remember some time after being with RCA in Camden that the vice-president of the RCA Manufacturing Company, Dr. W.R.G. Baker, who had come from General Electric, had just engineered a rather massive lay-off of engineers. He called the rest of us together in an auditorium. I remember him striding down the aisle after we were all seated there. He had dark-colored glasses on. He got up on the stage, looked down and said, "Hmm, I guess I didn't fire enough of you." That kind of atmosphere was pretty prevalent in those days.

Work on Luminescent Materials

Leverenz:

My first laboratory was a wooden-top bench on one side of a room, next to one corner of a sales auditorium on the seventh floor of Building 2. An end of a drain-pipe that was sticking up at one corner was the sink, the faucet for the water was across the room, there was an O. House pan balance, and the furnace was in a room way down at the far corner of the auditorium. I can still remember carrying red hot crucibles with tongs along the aisle in the dark during slide presentations to the sales force. The chap who passes the baton to me on making what we called "phosphors," luminescent materials, was M. Charles Banka, Charlie. He was an electrical engineer from the University of Illinois. We had a great time because I knew lots of stories from the West and from Germany, and he knew the stories from Illinois and the Mid-East. We had a couple of fancy weeks trading stories. As far as "phosphors," luminescent materials, are concerned, we had two reference standards at that time. Charlie Banka had been working with them, even though he was an electrical engineer. He had been doing this chemical work and doing it quite well, too. The first was a metal can of what's known as "willemite" that Dr. Zworykin had brought from Westinghouse, made by a ceramics man there according to a formula that had been devised by a Dr. W.S. Andrews, who had worked with Edison and later joined General Electric. The second reference standard was a zinc sulfide copper-activated material purchased from Eimer and Amend, a chemical supply house in New York City. That's the material that was used and is still used in so-called "radium watch dials", where it's excited by alpha particles. Both of those materials emitted green light when struck by electrons in cathode ray tubes.

The whole objective here was to try to achieve an all-electronic television. At that time, it was not at all certain that an all-electronic television could be achieved — when you think of the amount of power that was available at that time, measuring the beam current in micro amperes and the voltages of a few thousand volts. As I remember, we had about one-third of a watt of electron beam power. The objective was to produce a nice, great, big, bright television picture with about one-third of a watt. Nowadays, with improvements in electron guns and power supplies and other features, as well as very sizable improvements in the efficiencies of phosphors, luminescent materials, these tubes have a lot more power and the brightness is quite adequate. Both of those reference standard materials were green-emitting materials. I remember people looking at some of the early demonstrations and getting so fed up with seeing a green Mickey Mouse, a green mayor of Philadelphia, and a green everything. They started pleading, "Make it something else, just for a change, like yellow, for example." A further disadvantage of the zinc sulfide copper material was that the afterglow, its phosphorescence, was much too long, so if anything moved, such as a person shaking his head, it would blur. There would be a long comet-like tail after a baseball or a tennis ball flying through the air in the picture. Furthermore, that particular material had its efficiency greatly decreased by grinding, baking, and other things that had to be done to apply it in the actual kinescope. It was very sensitive to impurities.

We started with the zinc silicate manganese material, which was the willemite. That was a rugged material which could be treated or mistreated without too much difficulty. Its efficiency wasn't very high, but it was something that we could work with. It was and still is a standard material that emits the green light in oscilloscope tubes. One of the early things I did with that was substitute germanium for silicon. That became my first patent. It was a substantially yellower green light, and it turned out to be excellent for alpha particle excitation. As a matter of fact, shortly before the war, one of our people went to the United States Radium Company and, while talking about materials that might be useful in the war effort, he happened to mention the zinc germinate manganese. The U.S. Radium man knew almost to the month exactly how long would it be before that patent would expire. The next step in working from this oxygen-dominated material was to heat the material to 1,600 degrees Celsius, where it melted, and then quench it in a little platinum dish in water. Portions of that material would then assume a different crystal structure and have a much yellower emission. One of the troubles was that other portions didn't change, they kept the original crystal structure and still luminesced green, so we had to break the whole thing up. We had little powdery speckles of crystals. Under ultraviolet lights, with tweezers, we had to pick these yellow specks out of the total mass of green and yellow. I remember Harold Rhoades, the technician I had, saying after an hour or so, "This is like trying to pick fly manure out of pepper." Thus far all of the luminescent materials that were of any consequence had fixed colors. Whatever the color was, you couldn't change it by varying the constituents in the material. The next major step that I made was to partially substitute beryllium for the zinc in the zinc silicate manganese. I remember it was late one evening about six o'clock when we took that particular material, in a little platinum crucible, out of the furnace. I was with Harold Rhoades. After the thing had cooled, we put it under ultraviolet light and we saw it glowing a good, strong, healthy yellow. So we smiled, shook hands, and went home.

Fluorescent Lamps

Leverenz:

That particular material turned out to be my sixth and seventeenth patents. It was used in fluorescent lamps around the world. It had a controllable, changeable emission color that ranged from green to orange red, and its persistence under cathode rays was fine for television purposes. In the lamp field, the sequence went commercially from neon lamps to mercury discharge lamps — with the green emitting zinc silicate manganese for the green sign tubing of the 1930s — and then to the mercury discharge with a magnesium tungstate and my zinc beryllium silicate manganese to provide practical white fluorescent lamps. By agreement at the formation of RCA, the General Electric-RCA agreement forbade RCA to make and sell lamps. We helped GE, however, by transferring one of our people, H.R. Bob Shoenfeld, from the Harrison plant to the Nela Park plant of General Electric to give them a fast start in making and using the zinc beryllium silicate for fluorescent lamps.

On that one, I got the usual one dollar for the patent from RCA and nothing from General Electric, Westinghouse, or Sylvania; however, later on, I think it was 1954, I got a silver medal, the Brown Medal, from the Franklin Institute for my part of the contribution to practical fluorescent lamps. At the time of the presentation by the Franklin Institute, I was interested in the other two contributors, who came from Europe. It said in the write-up about them that mercury discharge, which was the basis for the modern fluorescent lamp, was the result of efforts to develop a rectifier using mercury vapor and an inert gas to make a power pack for a radio. So it's a contribution to the lighting field by the efforts to make better radios. For about two years after that, I went on with thousands of experiments, making further variations by introducing zirconium, thorium, titanium, and other allied materials into the zinc beryllium silicate manganese. I got a number of white-emitting phosphors, but I couldn't get the total efficiency up to the original zinc silicate manganese or zinc beryllium silicate manganese. Finally I realized that I could raise the output a little bit in this part of the spectrum, but I could do so only at the expense of the output in some other part. After a couple of years, I saw that it was a fruitless effort and abandoned that approach, but that was a white-emitting material all by itself.

At this point, I would like to insert that I was told — I believe it was by Dr. Gorton R. Fonda of the General Electric Research Laboratories, with whom I had many excellent conferences — that there was an internal document, largely the result of Dr. W. S. Andrew's work in General Electric, which stated that it was the considered opinion that luminescent materials were too inefficient to be considered for practical light sources. The incandescent lamp had its efficiency expressed in watts per candle; our research led to luminescent materials whose efficiencies were expressed in many candles per watt. It's similar to going from gallons per mile to miles per gallon, and it changed the whole lighting game.

In that connection, Irving Langmuir, a Nobel laureate, came to a demonstration of an early cathode ray tube at the General Electric Research Laboratory. Ray Kell, who later was with us, was present when Langmuir said, "See, I told you it was too dim to be considered for television." Langmuir refused to his dying day to have a television set in his house. He contributed enormously to practical incandescent lamps with the nitrogen filling. I contributed to the fluorescent lamp. In later years, when I married his niece, Edith Langmuir, Irving gave us silver candlesticks and we enjoyed dining by candlelight. Also, apropos of fluorescent lamps in these days of concern about energy, it's worth pointing out that someone in England during World War II calculated that for the operational life of one ton of phosphors in fluorescent lamps, there's a saving of 40,000 tons of coal used to generate electric power. A large part of this is the less power required for air conditioning because the fluorescent lamps are truly cold white instead of the heat poured out by the incandescent lamps. I think back to about 500 tons a year of fluorescent lamp phosphors in the first decade or so, and now they're probably over a thousand tons a year of fluorescent lamp phosphorous. That's saving about 440 million tons of coal, which is rather substantial.

Sulfur Dominated Materials

Leverenz:

Then we went away from the oxygen-dominated materials. We had a long struggle, sometimes it seemed almost impossible, to try to make something out of the sulfur-dominated materials, starting with zinc sulfide with a copper activator. As I mentioned before, they are extremely sensitive to impurities, and we were working in brick buildings with brick interior walls and brick dust flying around the place. A further peculiarity about the materials is that they needed a so-called flux, about two percent of sodium chloride during the crystallization at high temperatures, and the material, at least at that time, wasn't detectable in the final product. It was a good mystery as to why it was needed, but it was. After more than three years of efforts to purify zinc sulfide, helped by Elton J. Wood whom I lured away from California, we were able to convince management that we needed to have laboratories that were clean, with filtered air. We wore charged clothes and used water that we distilled ourselves. We eventually produced zinc sulfide that was pure enough that we could prove that the really pure zinc sulfide, when it was heated with sodium chloride, gave a light blue emission with a short afterglow. When you added only one part in a billion of copper, you got a green and the long afterglow of the kind of starting material we had. Then we found that when we put about one one-hundredth of a percent, or about fifty percent more in practice, of silver, we got a strong blue and a short afterglow that was just right for television purposes. That material, the zinc sulfide silver, is still the most efficient phosphor known for excitation by cathode rays, electrons. It's used in both black-and-white and colored kinescopes. Then, as a follow on to that, we prepared pure cadmium sulfide. By combining zinc and cadmium with silver activator in the same crystals, we got a strong yellow emitting material. Then we mixed that with the blue emitting zinc sulfide silver phosphor to produce the practical white-emitting screens in black-and-white kinescopes. Nowadays, the color television kinescopes use that same blue, whereas they had used for years a zinc cadmium sulfide with silver emitted green light, and another zinc cadmium sulfide with silver that emitted red light. Nowadays, the green emitting component is a zinc cadmium sulfide with copper and a different kind of what is known as a co-activator, and the red is an yttrium oxi-sulfide with an europium activator. It straddles the issue of being a oxygen- or sulfur-dominated material and does so beautifully.

Secondary Electron Emitters

Leverenz:

In addition to the main line of work on luminescent materials and literally synthesizing tens of thousands of things, testing, and following leads, and then abandoning certain leads that seem to fizzle out, there were other assignments that usually came from Dr. Zworykin, such as to work on making better secondary electron emitters which, when struck by one electron, would splash out four or ten. My chief contribution there, working in conjunction with Dr. John Ruedy and Dr. Zworykin, was a silver magnesium alloy which, when properly treated, had very practical advantages. Dr. Charlie Mueller later made some substantial contributions to that particular art. I was also given assignments to work on thermionic emitter coatings, enamels, and such like. Perhaps the chief thing that was helpful, particularly in the phosphor work, was the need to go to much higher temperatures with the electric furnaces of that day. I brought in people from the Globar Corporation, who sold furnaces and the silicon carbide electric resistance bars that at the time were running about up to 1,000 or maybe 1,100 degrees centigrade. They were very negative about attempts to go higher. Well, perhaps just out of shear ignorance, I designed, made, and operated furnaces that went up to over 1,600 degrees centigrade. I would have to get up at four o'clock in the morning, I remember, put clothes on over my pajamas, drive into the plant, start the cooling water to cool the electric terminals clamped onto the globars, and throw on the power so that when I came in at eight o'clock the furnace would be part way up to the 1,600 degrees centigrade. Otherwise, it wouldn't get there until about 5 o'clock. Once in a while I met some angry guards because the water connections had popped off and there was water all over the floor. I remember after the fluorescent lamp field had opened up and Globar furnaces were being made and sold in considerable quantities, for many decades I got Christmas cards from Mr. C.E. Barbu of the Globar Corporation as a continuing thank you for putting them into a much larger business than they had earlier envisioned.

Harrison, NJ

Leverenz:

In 1938 I was transferred to RCA's Harrison, NJ plant. There we were put in a building, I think it was Building #10. It was the first steel-reinforced concrete building made in the United States. It was built by Thomas A. Edison, as part of the Edison Lamp Works. There had been an earlier attempt by John C. Warner, who was head of the Harrison plant, to attract me to Harrison, but it hadn't come off, in part because Dr. Zworykin hadn't encouraged my transfer at that time. There was a man at the Harrison plant to whom we fed our research results from Camden; his name was Henry Kauffman. He was another electrical engineer, just as Charlie Banka had been originally. He told me that his boss, to whom I later reported, G.R. Shaw, told him some years after he had come on that the chief reason he hired him back in the Depression days was because he was cheap. I think he came in about $90 a month. But then in 1938, instead of simply a pull towards Harrison, there was a push-pull because Dr. Zworykin's interest had gone up enormously for electron microscopy. The Harrison people promised much more in terms of a really adequate laboratory that would be clean and suitable for the sort of work we had to do. So Elton Wood, Ross Shrader, Harold Rhoades, and I were transferred to Harrison.

FCC Hearings

Leverenz:

While we were there I was called to Washington several times to join in with other RCA people during the Federal Communications Commission's hearings on standards for black-and-white television. I remember Byron Jollife, Elmer Engstrom, a host of other people, and our lawyers were there, of course, during the hearings. Two of the major obstacles to getting the situation resolved were proposals from CBS and from Dumont. Dumont proposed that there should be more lines in the television picture and fewer fields, that is, the number of times that the picture was flashed per second based on a hypothetical concave downward decay phosphor. I remember one of the FCC commissioners asking, "Is Dumont doing research on phosphors?" The Dumont man, Dr. G.T. Goldsmith, said, "Oh, yes. We have our own ball mills and things like that." Which, of course, is asinine. I felt like jumping up and punching the fellow in the nose, but I was restrained because that didn't mean that they were making their own phosphors, they were just getting them from other people and putting them in the kinescopes. The decision on the standards was delayed by the advent of World War II.

Downward Cathode Ray Tube and Lancaster Plant

Leverenz:

At Harrison we went ahead and designed the acid process for phosphor production. I designed the Harrison production using large Pyrex bottles for the various reactions. Then, towards the beginning of World War II, I remember Ralph Beal, who was the RCA vice-president of research, took me aside very confidentially one day and asked if I could make a concave downward cathode ray tube screen — the very thing that we had said couldn't be done for the FCC hearings, because there was no such thing. Shortly after Beal's request, which mystified me, Gorton Fonda of General Electric asked for examples of our best long-persistence phosphors. I had conducted experiments with ultraviolet and blue-emitting screens whose light was impinged on green and yellow screens to make them glow outside of the kinescope. I knew that mathematically an exponential decay, ultraviolet or blue emission from one phosphor, could excite a resultant exponential decay yellow-emitting phosphor, in principle, to produce a downward concave decay, but there were no such phosphors. I was called to MIT and asked the same question that Mr. Beal asked me by Dr. Lee DuBridge and Dr. Bob Bacher, who were in charge of the Radiation Laboratory effort there. I said, "I believe it could be done by cascading, if we had the right kind of phosphors." So we got a contract and worked on it through the war. The whole contract totaled something over a quarter of a million dollars.

Most importantly, our work led to the Navy building the RCA-operated Lancaster plant to make radar kinescopes and other tubes for the war effort. RCA bought that plant after the war and owns it now. At Harrison, when I was still there and the Lancaster plant was being planned, I designed the phosphor plant for Lancaster and scaled it up to glass-lined kettles joined by Pyrex tubing for a semi-automated process. I remember that to make it a complete gravity feed I needed a seventy-foot high building. For esthetic reasons in the community they refused to let it be higher than 35 feet. It was the only building in the Lancaster plant that had an elevator, so we ran it down 35 feet and then put the kettles in elevators, raised them up 35 feet and ran down through for the next stage. One of the things that really tickled me about the design of that plant was that the very first batch passed the test. It was used in radar kinescopes. That was from that ultra-sensitive phosphor which was sensitive to one part in a billion of copper.

Clear through the war, we and the British, who had actually started before we had, tried to achieve that concave downward decay, but no one achieved it. The only materials that we had that were appropriate to excite first one with a cathode ray beam and have the light from that excite a second one were hyperbolic decay materials, but their persistence characteristics were inadequate to produce the kind of thing that theoretically could be envisioned. Nonetheless, those cascade screens using the sulfide phosphors were viewed in darkened rooms and were vital for the radars of Britain, Canada, and this country.

Princeton

Leverenz:

We moved to Princeton after the Lancaster operation was well along. Elton Wood and Ross Shrader came along with me, and I was back again reporting to Dr. Zworykin in Princeton. At that point, after we finished the Princeton laboratory, I looked back over the number of laboratories that I had moved and designed in Camden, Harrison, and Princeton, and I figured that I had spent at least three years designing and moving into laboratories out of something like nine years total with RCA at that point. Some time after the war Dr. Zworykin wanted me to transfer to Lancaster and was thinking of replacing me with a Dr. Roland Ward, who was a professor at Brooklyn Polytechnic Institute. I went to Lancaster and Dr. Dayton Ulery, who was in charge of a number of operations at Lancaster, took me on a tour of the phosphor plant, apparently unaware that I had designed it and worked closely with Ben Artau and John Markoski during its start up. Needless to say, I refused to go to Lancaster. Later on, I think it was 1956, the Lancaster phosphor plant was reproduced on a larger scale at Marion. As of early 1973, when I visited the Marion plant, they had produced since start up in 1956 over 1,000 tons of zinc sulfide and zinc cadmium sulfide phosphors. When I think of that, I would like to have had the opportunity to get, instead of my present pension, just a very small percentage of the net profit and savings that RCA had made, and still makes, from the Lancaster and Marion phosphor plants and the ferrite plant that was first in Camden, then in Findlay, Ohio and now in Indianapolis.

By the way, I will go back to the clean laboratories, which were so hard to come by and now are quite commonplace, in the making of transistors and integrated circuits. At the outset of the war, after we had gotten into making radar-type phosphors in kinescopes, a Dr. L.C. Justi from the General Electric Company Limited in England came to this country and visited the RCA phosphor labs in Princeton. I went over there a few weeks before D-Day. I found that Dr. Justi, who had quite a sense of humor, had come back from his trip to the United States and gone around telling people in England about these fabulous laboratories he had visited at RCA in Princeton. They had hospital-like cleanliness and linoleum walls, ceilings and floors, moistened rugs on the floor, and people changed their clothes and used triple-distilled water. He said, "The blighters wouldn't let me in because I have a dirty mind," and it's true — we kept the door locked.

Infrared Stimulable Phosphors

Leverenz:

Toward the latter part of the war, I was called in to a conference at the University of Rochester and asked to try to contribute to improve infrared stimulable phosphors, which were used in metascopes. The basic materials were, at that time, strontium sulfides with europium and samarium activators, that could be excited by ultraviolet light and then stimulated to glow in the dark by irradiating them with infrared. I made the contribution of partial substitution of selenium for the sulfur, to provide a superior material. This became another patent. The material in the metascopes was used in the Pacific theater of the war, but it was deliberately not used in Europe. When I was in England before D-Day, in addition to the radar mission which I had over there jointly with Dr. Wayne Nottingham of MIT, I gave a talk on these infrared stimulable phosphors at Teddington, which is the equivalent of our National Bureau of Standards. An English captain took notes, had them typed, and gave a complimentary copy to me. When it came time for me to return, all of my papers were put in the embassy pouch. After I had been back a week or so I got a telephone call from Washington. A chap there informed me that they were sending all of the papers that I had to me except for one, which was stamped "British Top Secret." I was not cleared for British Top Secret, so I couldn't have a copy. I still don't have a copy of what I said in Teddington about infrared stimulable phosphors!

Heyer:

Another strike for bureaucracy.

Ferrites

Leverenz:

Shortly after the end of the war, some of the information gathered particularly in Germany by Allied intelligence teams was made available to researchers over here. One of the items that attracted my attention was reports of attempts by the Germans to use certain iron and other oxide compositions, which are now called ferrites, as coatings to shield vessels from radar detection. I made a few of these ferrite materials. After that, we were visited by Dr. E. J. W. Verwey of Philips Laboratories in the Netherlands who told us, among other things, about some of their war time work on ferrites. A refinement of work that was accomplished chiefly by their researcher Dr. J. L. Snook in the 1930s. The Philips results triggered us to intensify our ferrite work, and I teamed chiefly with Bob Harvey and Pete Wentworth to produce ferrites that turned out to be mainstays for television deflection yokes, transformer cores, radio antennas, and later for computer memories. That plant is now an important part of our Indianapolis consumer products operation. I heard some time after we had published the results of our work on ferrites that Dr. Mervin J. Kelley, who was then president of Bell Telephone Laboratories, expressed great annoyance that we, without a magnetics research group, had come up with that before they did since they had a very sizable magnetics group headed by internationally known Dr. Bozorth. We did not develop a prime patent position in the ferrite field. Snook's work was dominant, particularly the 1936 work. Dr. Snook came to the United States and went to work for an organization in Ohio called Horizons and, unfortunately, was killed in an automobile accident. At some time during my early years of research on phosphors, when the word "phosphors" and all that was quite new and were just laboratory curiosities, with uncertainty about whether they were going to be used for anything practical, some internal reports and information about what we were doing got around the corporation. One of the RCA executives in New York City telephoned me and said he wanted to know if phosphors could be used to make a new RCA sign on the RCA building. He said they were going to take down the old one, which was made many years before, and then he said, "And there have been a lot of invocations since then." On the sad side, after the war I remember getting an air mail with all sorts of international stamps very well written with an impassioned appeal from a hat and cap merchant in Bombay, India. He wanted a phosphor for his wife, who had leukemia. I soon figured out that what he needed was radioactive phosphorus and I got in touch with the appropriate individual in the Atomic Energy Commission at Oak Ridge to respond to him. In a rather light-hearted article on phosphors, luminescent material, in 1943 in Radio Age, an internal publication of RCA, I mentioned "skintillions" of atoms that were emitting light in little phosphor crystals. Shortly after that a man called the RCA public relations to find out exactly how large is a skintillion.

Camera Tubes

Heyer:

You were involved in the camera tubes, the orthicon?

Leverenz:

I think the chief involvement that we had with the people in the pick-up tube or camera tube band came when they made a conscious effort to go to solid-state pick-up tubes, and particularly photo-conductors. Since we had some background in making crystalline materials — some of which, by the way, were photoconductive, zinc sulfide for example and cadmium sulfide — we had conferences about that. I don't know that we were anything other than just suppliers of materials for them to test. The real thought and invention there was due to Al Rose, Paul Weimer, Harold Law, Stan Forgue, Dan Colton, and that group, who devoted such a big chunk of their lives, their energies, and thoughts to devising the tubes that used solid-state materials instead of the previous orthicons and their predecessors.

Heyer:

I mention that because in talking to a number of these other people, they all say, "Thank God for Lefty Leverenz, he was the only one who knew anything about phosphors."

Leverenz:

We were glad that we could be helpful here and there. Some of our people became rather proficient in making and testing photoconductive materials. People such as Dr. S. M. Thomsen from the preparation side and Richard H. Bube, who is now a professor at Stanford University, from the standpoint of experiments — not in the pick-up tubes but simply on photoconductors as photoconductors.

Heyer:

In the area of kinescopes, particularly in the development of the shadow mask tubes, were red, green and blue phosphors well known? I believe that there was trouble in developing the red phosphors?

Leverenz:

There were great problems there. It's rather similar to the early days when we were trying to make single-color-emitting kinescopes, where we gravitated to the oxygen-dominated, like the zinc silicate manganese material, because it was so resistant to abuse during all the preparative steps of grinding it up, settling and baking it in the final tube. The same kind of problem, but with much greater complications, came in making the shadow mask tube, where there was a much more material inside the tube. There was the additional mask itself that could give off copper that could ruin sulfur-dominated materials. Early attempts were made with materials that were all oxygen-dominated. The efficiencies were rather low, and it was only after a long period of learning how to keep the processing of the entire interior of the tube, and the handling of the materials, free of the contaminants that would ruin the sulfide-type phosphors that it was possible to introduce the much more efficient all-sulfide type screens. Two of the constituents, the blue and the green, are still sulfide, and the other one is an oxy-sulfide.

Devising processes for introducing luminescent materials without having them contaminated by all the hardware in the color kinescope, the shadow mask, and so on made it a rough job. The people at our Lancaster plant in particular deserve a great deal of credit for the final stages of that, and one of the names that stands out is a man who is now in our semiconductor division, Dr. Joseph Donohue. He was notable for solving a lot of those practical problems. This was after Dr. Harold Law in our laboratories had made the original invention of the process for putting down the screen, following Al Schroeder's basic invention of the shadow mask kinescope itself. One of the fine features of working in RCA through all those years was the spirit of cooperation that was brought into practice without taking away the competitive spirit from people who were still trying to be creative in their own right. I have always wished that there could be some way in universities of encouraging students to help each other and still be creative in their own rights, instead of doing things all by themselves without that mutual reinforcement that can come from group effort.

World War II and Creative Cooperation

Heyer:

That spirit of helping each other might not have existed if people were in competition for patents for their own personal gain. Do you think that's true?

Leverenz:

I think it would still exist. If people were to get a substantial input as part of their actual productivity based upon what its real net profit contribution is, I should think that they would be likely to try even harder to come up with more ideas. I'm sure that the patent department would rejoice. Companies could be more selective about the projects that they insist on working on and patenting because they would want those that they are really going to pay off, instead of having a lot of chaff come through the system.

Heyer:

That's an interesting observation. However, if you have two people working in a similar area, one guy might not tell the other guy about his possible invention because of some fear that the other guy might do it first and grab the patent on it.

Leverenz:

During peacetime, commercial concerns were ultra-guarded in releasing information to competitors — usually this happened only after the patent had appeared. Along came the war and for patriotic and practical reasons, we resolved to let our hair down. We told each other about our processes, but as we went along I noticed that when representatives of General Electric, Sylvania, Westinghouse, and Marcels came together, as we did periodically, to talk about how we could do a better job on radar and other types of phosphors we would tell each other mostly about results that we had achieved. We were still permitted to patent in our own right. We took pride in our achievements, but we did not talk about what we expected to do. Part of that was because you could do a lot of speculating and we knew jolly well that in the phosphor field if you had one successful experiment out of 1,000 or 10,000, that was a high batting average. You would just be wasting people's time with all the speculations. The other reason was that if you did hit the jackpot on something like that, you didn't want some other people trying it before you did when it was your bright idea in the first place.

Heyer:

I wonder if that "letting your hair down" during the war was really significant? A lot of people have pointed to World War II as a real turning point for American industry. After the war, during the forties, there were things to buy but there was no money, then during the fifties people had money and there was plenty to buy and it really took off.

Leverenz:

You are speaking of creativity. I have read one book on the topic. It's a book called Creativity and Intelligence, in which an attempt was made with unusually gifted students to see if there was a correlation between creativity and intelligence. They failed to get any substantial correlation between those two. I think the only thing they did find a substantial correlation with was creativity and a sense of humor. [Laughter]

Industrial Production

Heyer:

A lot of your work was involved in setting up the plant. Do you want to elaborate on the sort of experiences that you had in that process? Those kinds of plants had never been built before.

Leverenz:

I remember drawing and having blueprints made of the scale-up of the Pyrex bottle process to using glass lined kettles, and being very apprehensive about whether the glass linings would contain impurities. I remember insisting on titanium silica compositions to keep cobalt out. Cobalt-type glass was the common lining for the pfaudler tanks. I just kept my fingers crossed that no impurities would come out of it and foul up these ultra-sensitive sulfide materials. The Pyrex piping I wasn't too afraid of, but I was afraid of the packing and the joints that would be in there. Those things had to withstand acid and they had to have a certain amount of suppleness, and I was uncertain about those constituents. I think what happened was that after we had run the thing on a mock basis and then flushed it with acid enough times, it leeched down. I finally came to the realization that I didn't need to have pure silica containers in order to keep alkali out — that Pyrex, after it had been used enough time, would have the alkali leeched out, and then essentially you were dealing with a Pyrex container that faced the solution as though it were pure silica, which was great. Another big thing that was working for us was the realization that, as you increase the volume of the batch, the surface that's exposed increases as the square of the radius considering it was a spherical batch, while the volume increases to the cube. So the bigger you make it, the lesser the proportion of exposure to areas where there could be contamination coming in. This worked and the first batch came out fine.

Heyer:

It must be one of the frustrating paradoxes of experimentation when you are working with very small batches.

Leverenz:

Right. There's a case where one thinks that it's in the laboratory that you will have the purest conditions, but in the large-scale manufacture you have a better chance of getting a purer product in actual practice. Of course, to cut costs and save time, there comes a realization that when you have a margin of safety in the large-scale process, people will relax their standards somewhat and coast along clear. I remember one of the tanks cracked. Bill Painter was with us in our Camden operation, one of the leading lights in the work on kinescopes overall. Bill is a very skinny guy. We had to have somebody who would go down the narrow opening of one of these 150-gallon kettles, and Bill was the only man who could squeeze his way down there and do some patching on a bit of the glass surface that had gotten disrupted, I think somebody dropped a wrench on it. Bill did it. Hurray!

Heyer:

How did he patch the glass?

Leverenz:

I have forgotten now. I suppose they had some kind of cement. In connection with that at the early part of the war — I wasn't present when this happened — we had a fellow by the name of Larry Thees, who was the head of the sales department of the Electronic Tube Division. A bunch of admirals and generals came in for a description of what RCA was capable of doing in its tube division. A number of the engineers and other people got up and presented flip-chart expositions on that. When that was all over Bill Painter happened to be sitting in the audience. He wasn't part of the team that was supposed to present. Larry Thees said, "Bill, get up there on the stage." Bill was mystified but he walked up there, shaking his head and just stood there like a fishing pole — no matter which angle you look he's just straight up and down. Larry said, "Bill, turn around." Bill slowly turned around, looked back. Larry said to the assemble generals and admiral and said, "Gentlemen, now there's a man whose really worked his fanny off for RCA." I have cleaned that up, too! [Laughter]

Flatscreen and 3-D TV

Heyer:

This morning when I was talking to Dr. Law, he was prognosticating about the future and we were talking about flatscreen television. Do you have anything in particular regarding that the difficulties thereof?

Leverenz:

Have you talked with Dr. Nicoll yet? I think Ted had an interesting approach to that. He said, "Supposing you took the present kinescope-type set and you were successful in making it thinner and thinner until you got to the point where it was so narrow that it would topple over.” I think that even if you could hang it on the wall, you are still going to get the same kind of picture. The program material is not going to be changed and that's the main thing. In fact, going way back to the early days in Harrison, I remember a man in the sales department giving a talk to the engineers. He said, "What is it that makes such and such an item in the current radio line of RCA sell so well?" He paused and then said, "I know what you are thinking — it's that new automatic gain control or that new this that and the other." He said, "That's hogwash." He said, "What makes radio sell is the programs that come over the air, that's the basic thing." So it's not going to change the nature of the program, which is the main thing that comes over the air to us. It could be a convenience in home decor, getting the box off the floor. On the other hand, some of us like these boxes. We have something that we can put ornaments on and lamps on. To put them on the wall where we are accustomed to seeing pictures, particularly when it's not in use, I think might be a hindrance rather than a help. Taking a jump ahead, they have been thinking all along about three-dimensional television. My own thesis on that is quite simple: the jump from black-and-white to color was a real positive input. There is no way of looking at a black-and-white picture and telling which is green, which is yellow, which is orange. All of those aesthetics and the riches that go with it are lost in a black-and-white picture. So you have a real gain in going to color. But if you look at a picture, whether it is black-and-white or color, you do have some idea whether something is behind something else because you have a feeling of scale size. The things farther back you see as smaller. You already know that there is a three-dimensional aspect to it. I don't see that we would gain all that much by trying to go to three dimensions.

Heyer:

You haven't mentioned the technical difficulties.

Leverenz:

This brings us to what I believe is most difficult in the kind of research companies such as RCA have to do. The most difficult job is trying to decide what it is that is really needed by people. Over the years I have been at social gatherings and I ask people, "What is it that you don't have in your household, or your automobile, or wherever it is that you are spending an appreciable amount of your life and that you would like to have?" The answer usually comes back, "Well, what have you got?" Once you know, as in the case of television, that there is a reasonable chance that the public would really go for it, then the technical problems are still tough, but I think the toughest problem is what would people really use, benefit from, and enjoy?

Heyer:

The video disk is a good upcoming test of that situation.

Leverenz:

That's right. We all hope, again going back to the program material that will be available in this format, that it will be very well received. But the test will be actually letting the consumer decide.

Heyer:

It's a big gamble at this point.

Leverenz:

It sure is. I would like to have all the Gilbert and Sullivan operettas, right on tap, any time I want to put them on. I would like to have the Masterpiece Theater performances available. There are a number of things of that type that I would like to see over and over again.

Heyer:

This is the breakthrough of the video age. It has never been possible before for people to have records such as these at their fingertips.

Leverenz:

We're seeing Masterpiece theater items for the second and even the third time because you miss new certain nuances the first time and enjoy them all over again.

Heyer:

I think, personally, this is going to open up a whole new area of in terms of film making. Films that always have suffered from the problem of having to be commercial because of the way they have been shown through theaters, where you have people come in and see them once and they have got to make a tremendous impact the first time. This is a whole different situation. Obviously a big battle is shaping up in the syndication front.

- People and organizations

- Engineers

- Inventors

- Communications

- TV

- Lasers, lighting & electrooptics

- Light sources

- Fluorescent lighting

- Engineered materials & dielectrics

- Elements

- Components, circuits, devices & systems

- Electron devices

- Cathode ray tubes

- Fields, waves & electromagnetics

- Magnetic devices

- Ferrite devices

- Signals

- Imaging

- Cameras & photography

- Culture and society

- Defense & security

- World War II

- Business, management & industry

- Industries

- Manufacturing industries

- News