First-Hand:Standing on the Shoulders of Giants: An Engineering Career in Consumer Electronics: Difference between revisions

No edit summary |

No edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Standing on the Shoulders of Giants: An Engineering Career in Consumer Electronics == | == Standing on the Shoulders of Giants: An Engineering Career in Consumer Electronics == | ||

Submitted by Lee H. Hoke, Jr., IEEE Life Fellow | |||

[[Image:50 year members.jpg|thumb|right]] | |||

[[Image:Stereo Receiver.jpg|thumb|right|Fig.1. Lab prototype of Philco’s first solid state AM-FM stereo receiver]] | [[Image:Stereo Receiver.jpg|thumb|right|Fig.1. Lab prototype of Philco’s first solid state AM-FM stereo receiver]] | ||

| Line 32: | Line 36: | ||

Finally, has electrical engineering in the consumer products sector been a good career? You bet. It’s all that I ever wanted to do! | Finally, has electrical engineering in the consumer products sector been a good career? You bet. It’s all that I ever wanted to do! | ||

== Related Documents == | |||

[[Media:News Scope.pdf|"Integrated Circuit Flip-Chips in Small Desk-top AM Radio"]], ''Electronic Design'', August 30, 1966. | |||

== References == | == References == | ||

<references /> | <references /> | ||

[[Category:Consumer_electronics|{{PAGENAME}}]] | |||

Revision as of 13:17, 22 October 2012

Standing on the Shoulders of Giants: An Engineering Career in Consumer Electronics

Submitted by Lee H. Hoke, Jr., IEEE Life Fellow

Paraphrasing the famous saying, “I have seen the future by standing on the shoulders of giants,” describes the path of my career in consumer electronics. Those giants were the members and leaders of the Electronics Advanced Development Lab at Philco Corp. in Philadelphia, PA in the early 1960’s. They were at the forefront of NTSC color TV development in the mid 50’s and documented their understanding and work as chapter authors and contributors in Donald Fink’s TV Engineering Handbook, McGraw Hill, 1957. Gentlemen such at Don Fink, himself, Wilson Boothroyd, Edgar Creamer, Abram Hopengarten, Harry Wilson, William Lancaster, Paul Wolfe and others were my early-career mentors.

Prior to college, my electronics background consisted of building and experimenting with radio and TV kits. Numerous one to five-tube radios led to assembling a TV receiver kit with 3” picture in 1948 as a 13-year old. Ben Zarfoss, a local TV store owner and serviceman, gave numerous hours of advice and assistance toward getting the unit to operate properly. This set was the first operating TV set on our street in Red Lion, PA. Improvements made within the next two years included increasing the picture size to 5” by the addition of a war-surplus oscilloscope CRT and addition of an all-channel VHF tuner. Favorite stations were WMAR Baltimore and “if the skip was in” Philadelphia 6. Later when WGAL-8 Lancaster, only 20 miles to the east, began telecasting we were provided a strong dependable signal.

I joined Philco as a Junior Engineer in February 1960 after receiving a BSEE from the University of Pennsylvania in 1956, serving a 7-month engineering internship with Bell Telephone of PA in Harrisburg and 3 years as a KC-97 navigator in the Strategic Air Command of the USAF. Training at Philco consisted of reading numerous documents written by mentors and others on AM-FM radio and television circuitry and broadcast transmission phenomenon which influenced reception performance. My technical skills were developed and sharpened by assisting senior engineers in building, testing and optimizing circuitry for their projects. Later on, major project involvement consisted of developing transistorized versions of vacuum tube circuits. For example, I was responsible for the AM-FM IF amplifier and FM stereo decoder for Philco’s first all-solid state hi-fi 50 watt stereo system which went into production in 1964 as model N1880.[1] The transistorization era for consumer products had begun. Today, that first lab prototype is still in operation as the sound system in my office and has required only replacement of the pilot lights and one paper capacitor over the years. Fig. 1. Transistor circuits have proven to be very reliable.

Early work under guidance of my supervisor, Bill Lancaster, in developing high-frequency transistorized IF amplifiers for radio and TV led to a project of instructing all the engineers in the radio and TV design labs in the technique of utilizing transistor admittance (‘y’) parameters to build stable, repeatable high-frequency multi-stage tuned amplifiers. Subsequently, all-transistorized products replaced the hybrid tube-transistor sets in Philco’s product line.

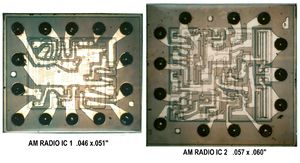

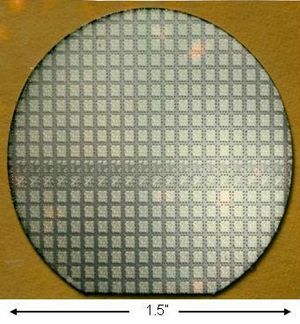

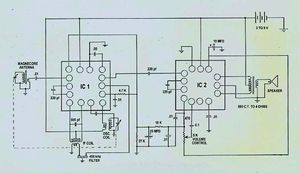

Next came the transition from transistors to integrated circuits. The manager of the Advanced Development Lab, Ed Creamer, long had a desire to build a wrist-watch radio as seen in the Dick Tracy comics. As integrated circuits were coming on the scene, he envisioned these devices as the basis for such a development and in 1964 gave Bill Lancaster and me the task of ‘inventing’ such a novel product. I spent two weeks at Fairchild Semiconductor in Sunnyvale, CA and many weeks with colleagues from Philco Semiconductor Division, Lansdale, PA to learn the design techniques for this new technology. What resulted was a lab prototype utilizing the largest wrist-watch case on the market with the antenna in the wrist strap. Two unique analog ICs containing the majority of circuitry for the AM receiver were developed, Fig. 2 & 3. Although the wrist radio was not a practical consumer commercial product, the ICs were put into production and a Philco desk-top ‘microelectronic’ radio model T1120WA was put on the market in August 1966, an industry first.[2][3][4] An early lab prototype shown in Figs. 4 & 5 is also still operating on the shelf of my office.

The next two years were spent full-time with the Philco-Ford Semiconductor Division in the development of several new ICs for use in radio and TV circuitry. In 1970, I transitioned back to the Philco-Ford Consumer Products Division as group leader for solid-state TV receiver development. In 1972, I left Philco-Ford and went to the Magnavox Co. in Fort Wayne, IN as chief engineer of console color TV sets. Our task was to change their TV product line from tubes to solid-state. The remainder of my career was spent with Magnavox in TV engineering management for all size sets, including large-screen projection units. In the late 1970’s Magnavox was purchased by Philips of the Netherlands and several name changes occurred, e.g., NAP Consumer Electronics and Philips Electronics of North America, but the product line names of Magnavox and Philips remained.

I served on the EIA R-4 TV Engineering Committee as member (1976-1988) and as Chairman (1982-1985) and was leader of the industry committee for TV Multichannel Sound Development and Broadcast/Cable Channel Standardization. IEEE activities consisted of being a member of the Technical Program Committee of the International Conference on Consumer Electronics, committee chair and later conference chair. I also served on the Administrative Committee (AdCom) of the CE Society for several terms from 1989 to 2010 and as CE Society treasurer from year 2000 to 2010. In retirement, I have kept touch with the industry by being an active member of the paper review committee for the IEEE Transactions on Consumer Electronics.

In 1983 I was contacted by K. Blair Benson who was preparing to update the original Fink ‘Television Engineering Handbook’. I considered it an honor and responsibility to younger TV engineers to share my knowledge of TV systems. The new handbook was published in 1985. Chapter 13 which describes up-to-date TV receiver circuitry and concepts written by colleagues at NAP Consumer Electronics (Philips) is the update to the 1957 original. I have also contributed chapters on radio and TV receiver circuit design in Fink & Christiansen, Electronics Engineers’ Handbook, 3rd edition’, McGraw Hill 1989; and Christiansen, Alexander & Jurgen, Standard Handbook of Electronic Engineering, 5th Edition, McGraw Hill, 2005. During my career I received 4 U.S. patents on radio and TV circuit innovations and published over 20 papers in technical magazines and IEEE Transactions. In 1994 the IEEE honored me by elevating my membership status to Fellow. So now, I guess that tags me as one of the giants.

Not only have I experienced the transition from vacuum tubes to transistors and later, integrated circuits, I have also witnessed the transition of consumer electronic manufacturing. In the 50’s and 60’s, Philco-Ford’s manufacturing facility was located across the street from the design labs in Philadelphia, PA. A major project undertaken in the TV design lab was to develop a robotic machine to do the alignment of all pots and coils on a TV chassis, thus reducing labor cost and increasing output. As the first prototype unit was being put into operation ‘across the street’, Ford, the company owners, decided that TV chassis assembly could be done more cheaply in Brazil at the site of one of their automotive engine plants. That transition proved to be problematic and the Philco TV business was closed a couple years later.

In the 60’s through 80’s Magnavox TV production was located at plants in East Tennessee – Jefferson City, Morristown and Greeneville. In 1980, engineering was relocated from Fort Wayne, IN to Knoxville, TN, 60 miles from the plants, in order to have closer coupling between engineering and manufacturing. This operated successfully. In 1990, however, Philips, now owner of the company, opened a manufacturing facility in Juarez, Mexico and moved all table-model TV production there. Consoles – the large floor-model cabinet sets - remained in Greeneville. As the consumer’s choice for floor-model TV’s decreased throughout the late 90’s the loading of the Tennessee plants decreased with their eventual closing as TV plants. Production for RCA, a U.S. TV competitor, gradually shifted from Indianapolis and Bloomington, IN to their plants in Taiwan. By the mid 2000’s, Zenith, now owned by Lucky Goldstar, was the only American name still in the TV business, however much of their manufacturing had been transitioned to Mexico. So TV manufacturing has totally moved out of the U.S. and currently is centered in China. Several Japanese-name companies have also moved manufacturing to China. Is the next stop to be India where wages are still low, or perhaps Africa?

Finally, has electrical engineering in the consumer products sector been a good career? You bet. It’s all that I ever wanted to do!

Related Documents

"Integrated Circuit Flip-Chips in Small Desk-top AM Radio", Electronic Design, August 30, 1966.

References

- ↑ H.E. Dow, et al. “Economical solid state stereo radio-phonograph designs”, IEEE Trans. on Broadcast and Television Receivers, vol. BTR-11, no. 1, pp. 13-18, May 1965.

- ↑ News Scope, “Integrated-circuit flip-chips in small desk-top AM radio”, Electronic Design Magazine, pg.18, August 30, 1966

- ↑ L.H. Hoke, Jr., Design of a monolithic integrated AM receiver for the consumer market, MSEE Thesis, Univ. of Pennsylvania, 1956

- ↑ L.H. Hoke, Jr., et al, “Monolithic circuits for radio receivers”, IEEE Trans. on Broadcast and Television Receivers (Chicago Spring Conference), BTR-13, no. 2, pp. 64-71, July 1967; also recipient of the Best Paper Award at that conference.