Eimac

Eimac - Vacuum Tubes

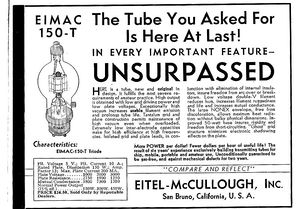

A very small advertisement in the November, 1934, issue of QST magazine announced that a new tube, "unsurpassed in every important feature" was available from an obscure company in California. The company was Eitel-McCullough, Inc., and the tube was the 150T.

How did it all start?

In 1932 two radio amateurs, Jack McCullough (W6CHE) and Bill Eitel (W6UF), decided to build high power transmitters to work some of the 20 meter overseas stations being heard in California. They found to their dismay that the expensive transmitting tube they purchased refused to work at 1,000 volts-and that was all the high voltage their supply would provide for them.

They decided they could build a better tube themselves that would work at low voltage. They borrowed a modest sum and in 1934 started a company with only three people. The product was the 150T triode. From this humble beginning, the company expanded steadily. Other tubes were added to the line and the number of personnel increased slowly.

In late 1935 some tubes were sold to the U.S. Naval Research Laboratory for use in an experimental radar set that worked on 200 MHz. The 50T was the only tube that provided sufficient pulse power and that was able to stand up to the high plate voltage. More tubes were ordered by the military and in 1939 the first Navy sea radar tests used EIMAC tubes.

During 1938, the U.S. airways were developing radio beacons and high frequency radio links all over the United States. A new EIMAC tube type (450TH) was chosen for this service, and a number of other types were used for broadcast radio, including the newly-developed Armstrong FM broadcast service, and experimental television service. Radio amateurs worldwide also used EIMAC tubes as their popularity grew and dependability became known.

In 1940 the company received its first big war order from Western Electric for the delivery of 10,000 tubes! Up to now, an order for fifty tubes would be a cause for celebration. Converti ng from hand methods to mass production kept everyone working night and day for months, sent the hiring rate skyrocketing and tossed out all standard methods and routines. By July, 1941, the original staff was ten times as large as it was a year earlier and the plant was doubled in size to accommodate the work. Expansion of the company was so fast that a second plant was opened in Salt Lake City, Utah. By 1945, EIMAC had grown to over 1800 people and nearly 3,500 tubes per day of all types were being manufactured.

With the end of hostilities in 1945 and the cancellation of government contracts brought about a crisis at Eitel McCullough, Inc. Production levels fell to near-zero as government stocks of surplus tubes were dumped on the market for as little as fifteen cents each. The Salt Lake City plant was closed.

Foreseeing the end of the war, however, EIMAC engineers had evolved new tube types, including production of the new beam tetrode (4X150A) which performed well in the VHF region. At the same time, a new Salt Lake City plant was opened to make television picture tubes(CRT). The future of the company no longer depended upon the older tubes so plentiful on the surplus market. One feature of the Salt Lake City plant was that it manufactured every component of the tube under the one roof.

In 1958 a new Eitel-McCullough plant was built in San Carlos, California, for production of new tetrode tubes, plus larger tubes for broadcast and TV service. At the same time, TV klystrons and other microwave devices were developed for troposcatter communications.

In 1965, Eitel-McCullough merged with Varian Associates of Palo Alto, California. The Varian EIMAC divisions continue to produce all types of transmitting tubes, and are known worldwide as a leader in advanced tube design. Super-power tubes were developed and built for broadcast service, with up to 1.5 megawatt anode dissipation, and special tube types are constantly being developed for research studies and experimentation.

Varian EIMAC has pioneered the use of Pyrolytic grids in power tubes for the broadcast industry, making use of a 'novel laser-milling operation to achieve increased tube performance, stability and higher power output.

Modern Varian EIMAC manufacturing techniques have led to improved VHF performance in large power grid tubes, such as the 4CW300,000G. Other modern Varian EIMAC products are used in the Department of Energy's fusion research program.

The latest development, the Klystrode, combines the better features of the klystron and the tetrode and is in production along with many other new tubes.

Bill Eitel and Jack McCullough, although both were retired in 1984, are still interested in the company and, of course, are still very active radio amateurs. The EIMAC divisions of Varian owe a great deal to amateur radio for it was in this field that many of the early transmitting tubes proved their worth and-even today-many of the company's customers are radio amateurs.

As Bill and Jack say, "If it were not for amateur radio, EIMAC could never have existed."

Eimac People

Many of the people working at Eimac were amateur radio operators:

Robert I. "Bob" Sutherland, (1926-2004) W6PO (ex-W6UOV) was on the West Coast end of the first Amateur Radio moonbounce (EME) contact in 1960 when the Eimac Radio Club's W6HB and W1BU worked each other on 1296 MHz EME. An employee of tube manufacturer Eimac for nearly 50 years, Sutherland, who directed the Advanced Products Lab, developed some of the more famous Eimac tube-based amps. His Eimac 8877 VHF amplifier design still is referred to as "the W6PO amp."

http://www.arrl.org/news/stories/2004/03/11/2/?nc=1

http://sutherland.blogs.com/w6po/