Eimac: Difference between revisions

| Line 11: | Line 11: | ||

[[Image:Eitel Mccullough.jpg|thumb|right]] | [[Image:Eitel Mccullough.jpg|thumb|right]] | ||

[[Image:Eitel Lunch room.jpg|thumb|right]] | [[Image:Eitel Lunch room.jpg|thumb|right]] | ||

[[Image:Eitel-McCullough1.jpg|thumb|right]] | [[Image:Eitel-McCullough1.jpg|thumb|right]] | ||

[[Image:Eitel-McCullough2.jpg|thumb|right]] | [[Image:Eitel-McCullough2.jpg|thumb|right]] | ||

[[Image:Eitel badge.jpg|thumb|right]] | [[Image:Eitel badge.jpg|thumb|right]] | ||

[[Image:Eimac visitor.jpg|thumb|right]] | [[Image:Eimac visitor.jpg|thumb|right]] | ||

| Line 29: | Line 29: | ||

In late 1935 some tubes were sold to the U.S. Naval Research Laboratory for use in an experimental [[Radar|radar]] set that worked on 200 MHz. The 50T was the only tube that provided sufficient pulse power and that was able to stand up to the high plate voltage. More tubes were ordered by the military and in 1939 the first Navy sea radar tests used EIMAC tubes. | In late 1935 some tubes were sold to the U.S. Naval Research Laboratory for use in an experimental [[Radar|radar]] set that worked on 200 MHz. The 50T was the only tube that provided sufficient pulse power and that was able to stand up to the high plate voltage. More tubes were ordered by the military and in 1939 the first Navy sea radar tests used EIMAC tubes. | ||

During 1938, the U.S. airways were developing [[Radio|radio]] beacons and high frequency radio links all over the United States. A new EIMAC tube type (450TH) was chosen for this service, and a number of other types were used for broadcast radio, including the newly-developed Armstrong [[FM Radio|FM broadcast]] service, and experimental television service. Radio amateurs worldwide also used EIMAC tubes as their popularity grew and dependability became known. | During 1938, the U.S. airways were developing [[Radio|radio]] beacons and high frequency radio links all over the United States. A new EIMAC tube type (450TH) was chosen for this service, and a number of other types were used for broadcast radio, including the newly-developed Armstrong [[FM Radio|FM broadcast]] service, and experimental television service. Radio amateurs worldwide also used EIMAC tubes as their popularity grew and dependability became known. Eitel and Armstrong were close and regularly met to discuss problems and fixes. Here is an extract of one such collaboration. | ||

In 1940 the company received its first big war order from Western Electric for the delivery of 10,000 tubes! Up to now, an order for fifty tubes would be a cause for celebration. Converting the plant from using hand methods to mass production kept everyone working night and day for months, sent the hiring rate skyrocketing and tossed out all standard construction methods and routines. By July, 1941, the original staff was some ten times as large as it was a year earlier and the plant was doubled in size to accommodate the growing work. Expansion of the company was so fast that a second plant was opened in Salt Lake City, Utah. By 1945, EIMAC had grown to employing over 1800 people and nearly 3,500 vacuum tubes per day of all types were being manufactured. | In 1940 the company received its first big war order from Western Electric for the delivery of 10,000 tubes! Up to now, an order for fifty tubes would be a cause for celebration. Converting the plant from using hand methods to mass production kept everyone working night and day for months, sent the hiring rate skyrocketing and tossed out all standard construction methods and routines. By July, 1941, the original staff was some ten times as large as it was a year earlier and the plant was doubled in size to accommodate the growing work. Expansion of the company was so fast that a second plant was opened in Salt Lake City, Utah. By 1945, EIMAC had grown to employing over 1800 people and nearly 3,500 vacuum tubes per day of all types were being manufactured. | ||

| Line 57: | Line 57: | ||

In 1997, the Salt Lake plant was moved to San Carlos and much of the expertise in the construction of planar triodes was lost. Eimac continued to make tubes like the Y-739F and the smaller planar tubes, but it was a struggle. In 2007, the plant in San Carlos was moved to Palo Alto and incorporated into the CPII facilities. The San Carlos plant was bull-dozed a year later and today is a recycling yard. | In 1997, the Salt Lake plant was moved to San Carlos and much of the expertise in the construction of planar triodes was lost. Eimac continued to make tubes like the Y-739F and the smaller planar tubes, but it was a struggle. In 2007, the plant in San Carlos was moved to Palo Alto and incorporated into the CPII facilities. The San Carlos plant was bull-dozed a year later and today is a recycling yard. | ||

Also see ;http://www.cpii.com/history.cfm; The name Eimac is retained as a Trademark of CPII. | Also see ;http://www.cpii.com/history.cfm; The name Eimac is retained as a Trademark of CPII. | ||

== Eimac People == | == Eimac People == | ||

Revision as of 22:34, 28 November 2011

Eimac - Vacuum Tube Manufacturing

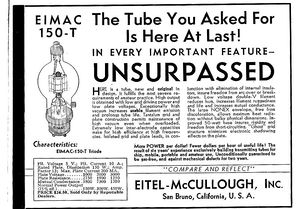

A very small advertisement in the November, 1934, issue of QST magazine announced that a new tube, "unsurpassed in every important feature" was available from an obscure company in California. The company was Eitel-McCullough, Inc., and the tube was the 150T.

How did it all start?

In 1932 two radio amateurs, Jack McCullough (W6CHE) and Bill Eitel (W6UF), decided to build high power transmitters to work some of the 20 meter overseas stations being heard in California. They found to their dismay that the expensive transmitting tube they purchased refused to work at 1,000 volts and that was all the high voltage their power supply would provide for them.

They decided they could build a better tube themselves that would work at low voltage. They borrowed a modest sum and in 1934 started a company with only three people. The product was the 150T triode. From this humble beginning, the company expanded steadily. Other tubes were added to the line and the number of personnel increased slowly.

In late 1935 some tubes were sold to the U.S. Naval Research Laboratory for use in an experimental radar set that worked on 200 MHz. The 50T was the only tube that provided sufficient pulse power and that was able to stand up to the high plate voltage. More tubes were ordered by the military and in 1939 the first Navy sea radar tests used EIMAC tubes.

During 1938, the U.S. airways were developing radio beacons and high frequency radio links all over the United States. A new EIMAC tube type (450TH) was chosen for this service, and a number of other types were used for broadcast radio, including the newly-developed Armstrong FM broadcast service, and experimental television service. Radio amateurs worldwide also used EIMAC tubes as their popularity grew and dependability became known. Eitel and Armstrong were close and regularly met to discuss problems and fixes. Here is an extract of one such collaboration.

In 1940 the company received its first big war order from Western Electric for the delivery of 10,000 tubes! Up to now, an order for fifty tubes would be a cause for celebration. Converting the plant from using hand methods to mass production kept everyone working night and day for months, sent the hiring rate skyrocketing and tossed out all standard construction methods and routines. By July, 1941, the original staff was some ten times as large as it was a year earlier and the plant was doubled in size to accommodate the growing work. Expansion of the company was so fast that a second plant was opened in Salt Lake City, Utah. By 1945, EIMAC had grown to employing over 1800 people and nearly 3,500 vacuum tubes per day of all types were being manufactured.

With the end of hostilities in 1945 and the subsequent cancellation of government contracts brought about a crisis at Eitel McCullough, Inc. Tube production levels fell to near-zero as government stocks of surplus tubes were dumped on the market for as little as fifteen cents each. The Salt Lake City plant was sadly closed.

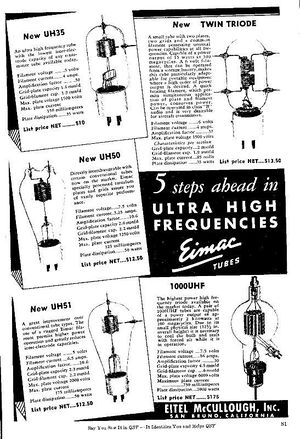

Foreseeing the end of the war, however, EIMAC engineers had evolved new tube types, including production of the new beam tetrode (4X150A) which performed well in the VHF region. At the same time, a new Salt Lake City plant was opened to make television picture tubes (CRT's). The future of the company now no longer depended upon the older tubes that were so plentiful on the surplus market. One feature of the Salt Lake City plant was that it manufactured every component of the tube under the one roof.

In 1958 a new Eitel-McCullough plant was built in San Carlos, California, for production of new tetrode tubes, plus larger tubes for broadcast and TV service. At the same time, TV klystrons and other microwave devices were developed for troposcatter communications.

In 1965, Eitel-McCullough merged with Varian Associates of Palo Alto, California. The Varian EIMAC divisions continue to produce all types of transmitting tubes, and are known worldwide as a leader in advanced tube design. Super-power tubes were developed and built for broadcast service, with up to 1.5 megawatt anode dissipation, and special tube types are constantly being developed for research studies and experimentation.

Varian EIMAC has pioneered the use of Pyrolytic grids in power tubes for the broadcast industry, making use of a 'novel laser-milling operation to achieve increased tube performance, stability and higher power output.

Modern Varian EIMAC manufacturing techniques have led to improved VHF performance in large power grid tubes, such as the 4CW300,000G. Other modern Varian EIMAC products are used in the Department of Energy's fusion research program.

The latest development, the Klystrode, combines the better features of the klystron and the tetrode and is in production along with many other new tubes.

In 1984, Bill Eitel and Jack McCullough both retired, and maintained a strong interest in the company and, of course, in their amateur radio activities. The EIMAC divisions of Varian owe a great deal to amateur radio for it was in this field that many of the early transmitting tubes proved their worth and-even today-many of the company's customers are radio amateurs.

As Bill and Jack said, "If it were not for amateur radio, EIMAC could never have existed."

In 1989, as a result of the energy efficient performance of the Klystrode® inductive output tube (IOT), the Eimac Division of Varian Associates was awarded an Emmy® Award for technological achievement by the Academy of Television Arts and Sciences. The Klystrode IOT used in television transmitters at WCES in Augusta, Ga. was the first of the high-power output devices to be on-air for UHF television broadcasting.

At 301 Industrial Road in San Carlos was a plant built specifically as a dedicated tube manufacturing operation, not some building that has been adapted or re-purposed into that kind of function. In 1995, Leonard Green & Partners purchased the entire Electron Devices Business from Varian and formed Communications & Power Industries, Inc. (CPII)

In 1997, the Salt Lake plant was moved to San Carlos and much of the expertise in the construction of planar triodes was lost. Eimac continued to make tubes like the Y-739F and the smaller planar tubes, but it was a struggle. In 2007, the plant in San Carlos was moved to Palo Alto and incorporated into the CPII facilities. The San Carlos plant was bull-dozed a year later and today is a recycling yard.

Also see ;http://www.cpii.com/history.cfm; The name Eimac is retained as a Trademark of CPII.

Eimac People

Many of the people working at Eimac were amateur radio operators, and indeed made significant contributions outside their Eimac interests:

- Jack A. McCullough (1907-2001), ex-W6CHE, of Cupertino, California, died April 28, 2001. He was 93 and an ARRL Life Member. McCullough also was a QST author in the 1930s and 1940s, writing mostly about what he knew best--high-power amplifier tubes. He was born in 1907 in San Francisco, California, received the amateur callsign 6CHE, ca. 1924, and attended college for two years. He joined the tube-and equipment-maker Heintz & Kaufman in January 1930, shortly after H & K hired his future partner Bill Eitel, W6UF. He and Eitel left H & K in 1934 to form Eimac after the firm's decision not to sell tubes into the amateur radio market. The US Navy gave him its Distinguished Public Service Award in 1950. He was elected as a Fellow of the Institute of Radio Engineers in 1953 for "pioneering contributions to power tube design." He became a Fellow of the Radio Club of America, receiving its Ralph Batcher Award in 1979 and its Sarnoff Citation in 1994. He was an active contributor to Stanford University, where the new McCullough Engineering Building now honors him.

- W (Bill) W. Eitel (1908-1989), ex-W6UF, received the grade of Fellow in The Institute of Radio Engineers on January 1, 1953, and was a licensed Professional Engineer in the State of California. Mr. Eitel was a member of the board of trustees of the Foundation for Nutrition and Stress Research; Chairman of the Board of OSCAR Inc., a satellite company, and was the owner and operator of the Sutro Ranch and Laboratory in Dayton, Nevada. Bill Eitel was a remarkable character, he never actually completed high school because his parents moved too often. However, some notes in the files show him to have been a fine manufacturing engineer. Simultaneously with installing the first (wartime) Salt Lake City plant, he found that supplies of tungsten for their tube parts were too tight and difficult to obtain. So he and his people built their own plant to reduce CaWO4 and sinter it into rod form for their vacuum tubes.Billpassed away February 26 1989 in Palm Springs.

- George Badger was another standout engineer. He was one of the earlier graduate engineers to be hired, ca. 1951, and worked on all manner of projects, like running the laboratory facility that attempted to adapt the Lawrence color-TV picture tube for production. Eimac was making Black and White picture tubes for RCA Victor at their Salt Lake City plant at the time). He headed up an important competitive “save” from RCA in the late ‘50s. He also got one of the media-industry awards, an Oscar I think, for development of the klystrode. After George’s retirement, he ran the marketing operation for Svetlana America, and when that folded, he moved to Econco. He was employed in the tube business until his death around 2009.

- Bill Orr...

- Jack Kendall...

- Bill Sain.... tube engineer and others who built the product line in the 60's and 70's.

- Robert I. "Bob" Sutherland, (1926-2004) W6PO (ex-W6UOV) was on the West Coast end of the first Amateur Radio moonbounce (EME) contact in 1960 when the Eimac Radio Club's W6HB and W1BU worked each other on 1296 MHz EME. An employee of tube manufacturer Eimac for nearly 50 years, Sutherland, who directed the Advanced Products Lab, developed some of the more famous Eimac tube-based amps. His Eimac 8877 VHF amplifier design still is referred to as "the W6PO amp."

- Reid Brandon...

- Joseph (Buzz) Miklos...

- Willis B. Foote, Chief Specifications Engineer, Power Grid Division

See; also:

http://www.arrl.org/news/stories/2004/03/11/2/?nc=1

http://sutherland.blogs.com/w6po/

Archives & Manufacturing data

The Tube Collectors Association is the current caretaker of the Perham-Eimac Archive. The Perham-Eimac Archive consists of 48 shelf-feet of Eimac tube manufacturing information from 1942 to 1960 plus several cabinets of legal and miscellaneous information. this archive is available by arrangement to anyone wanting to do tube research. Please contact Ludwell Sibley, Oregon, if interested in using these archives. ** interesting follow up...

Acknowledgements and request for comments, photos, memorabilia etc.

Much of the information collected here is a result of gracious and sharing individuals. If you can assist in expanding any information, please ask any member of IEEE to help you upload information here, or contact the IEEE History Committee - who will be ecstatic to assist. (or; e-mail David at k3hz@ieee.org )

Photo Archive.

Please refer to the individual photo metadata for contributor acknowledgements and related information.