|

|

| (25 intermediate revisions by 2 users not shown) |

| Line 3: |

Line 3: |

| Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock | | Transformers at Pittsfield: A History of the General Electric Large Power Transformer Plant at Pittsfield, Massachusetts, by Thomas J. Blalock |

|

| |

|

| In 1886, William Stanley first successfully demonstrated the use of the transformer in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts.

| | [[Image:Blalock - book cover.jpg|thumb|center|400px]] |

|

| |

|

| In 1986, the General Electric Company announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before. | | In 1886, [[William Stanley|William Stanley]] first successfully demonstrated the use of the [[Transformers|transformer]] in an alternating current system to provide electric lights for the Town of Great Barrington, Massachusetts. |

| | |

| | In 1986, the [[General Electric (GE)|General Electric Company]] announced that it would be closing its Large Power Transformer Operation in nearby Pittsfield. The existence of this plant was a direct result of Stanley's work one hundred years before. |

|

| |

|

| The technology associated with the design and manufacture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a foreign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands. | | The technology associated with the design and manufacture of transformers in Pittsfield was sold to the Westinghouse Corporation, which built large transformers at a plant in Muncie, Indiana. However, about a year later, Westinghouse sold its Muncie operation to a foreign conglomerate known as "ABB" (ASEA - Brown-Boveri). Thus, one hundred years of transformer technology which had developed in the Berkshires of Western Massachusetts fell, unceremoniously, into foreign hands. |

| Line 23: |

Line 25: |

| The men who headed the Pittsfield Transformer Operation during its eighty years of existence as a part of General Electric were (their actual titles changed from time to time as the corporate organization changed): | | The men who headed the Pittsfield Transformer Operation during its eighty years of existence as a part of General Electric were (their actual titles changed from time to time as the corporate organization changed): |

|

| |

|

| *Cummings C. Chesney | | *[[Cummings C. Chesney|Cummings C. Chesney]] |

| *Edward Wagner | | *Edward Wagner |

| *Louis Underwood | | *Louis Underwood |

| Line 52: |

Line 54: |

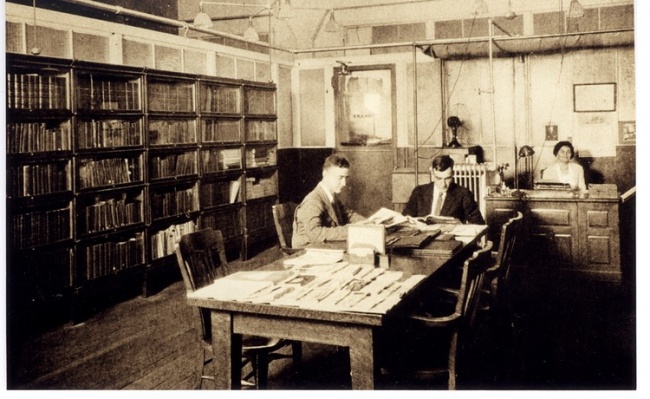

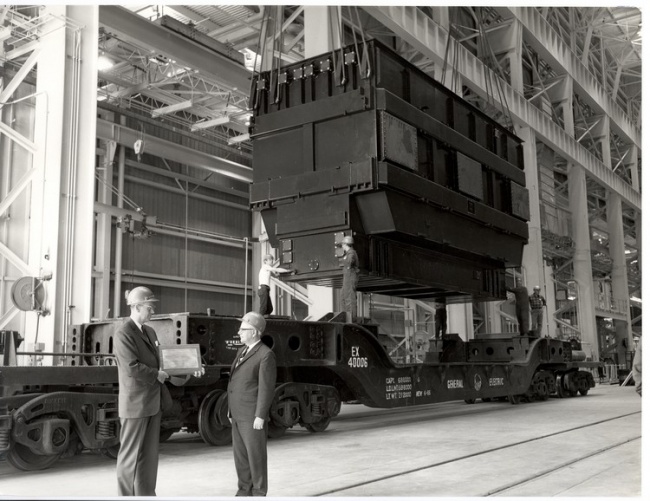

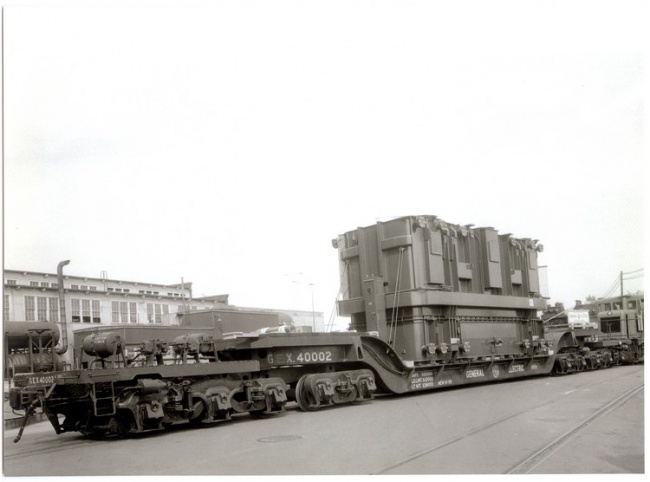

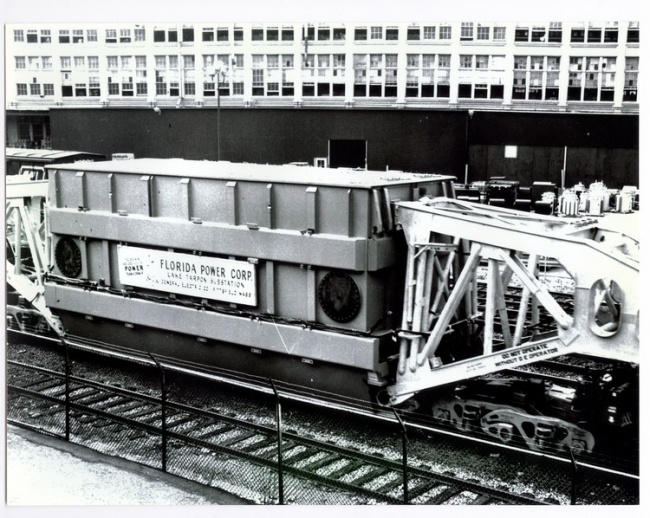

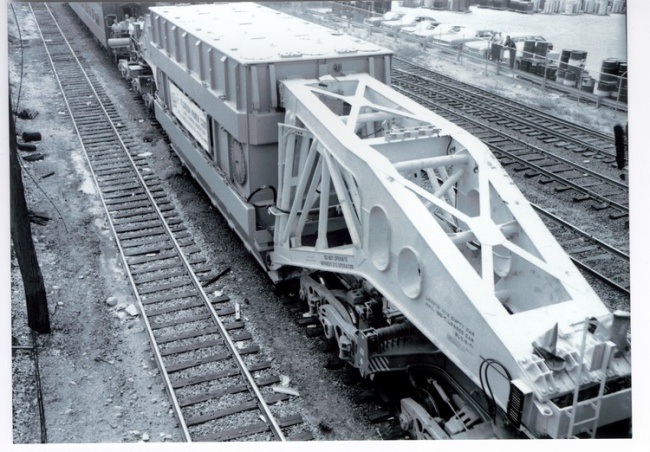

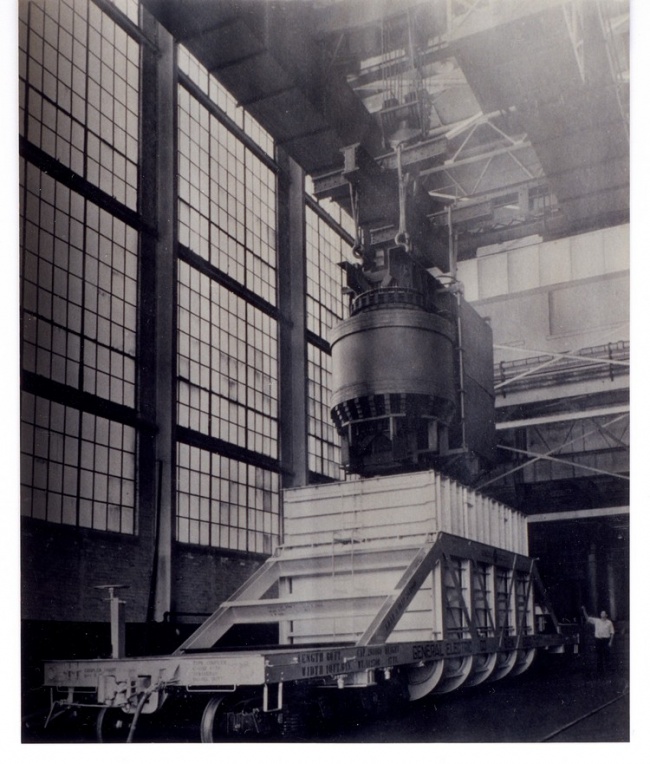

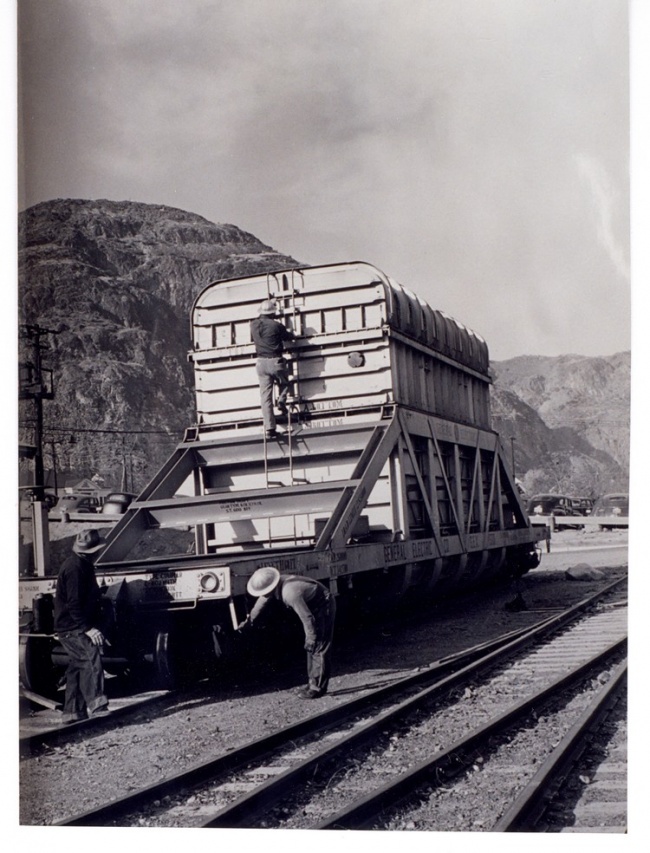

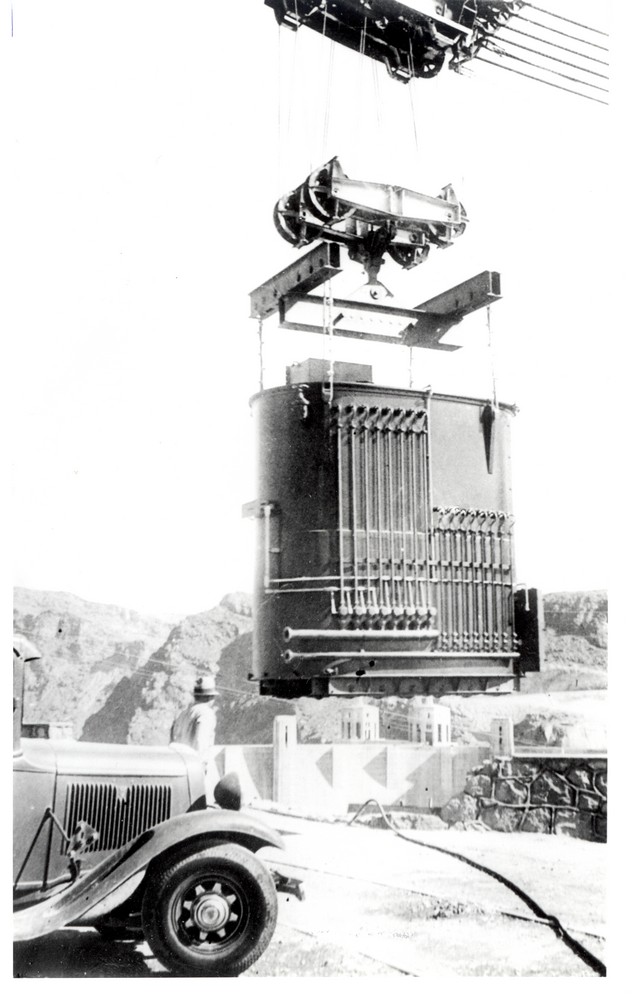

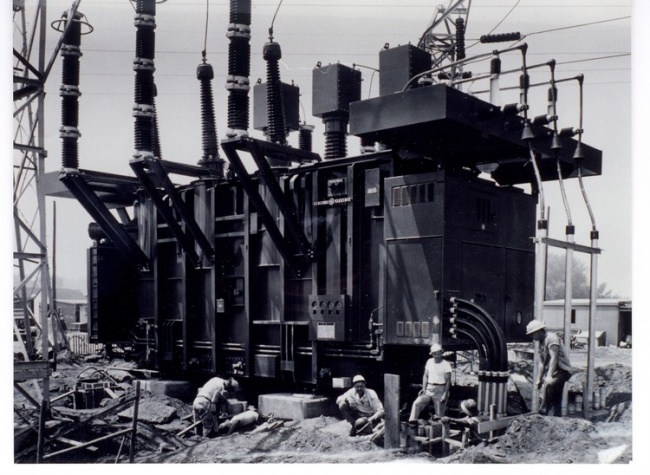

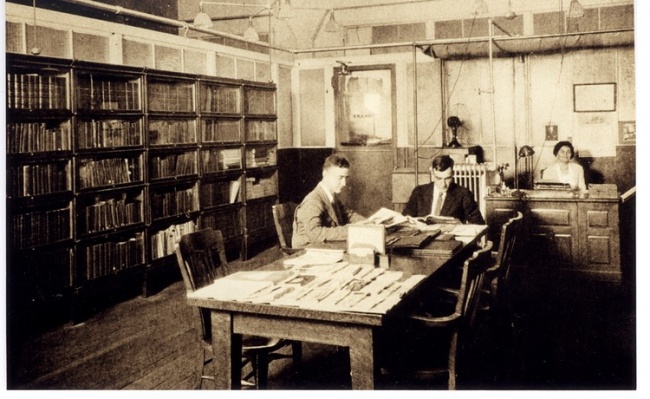

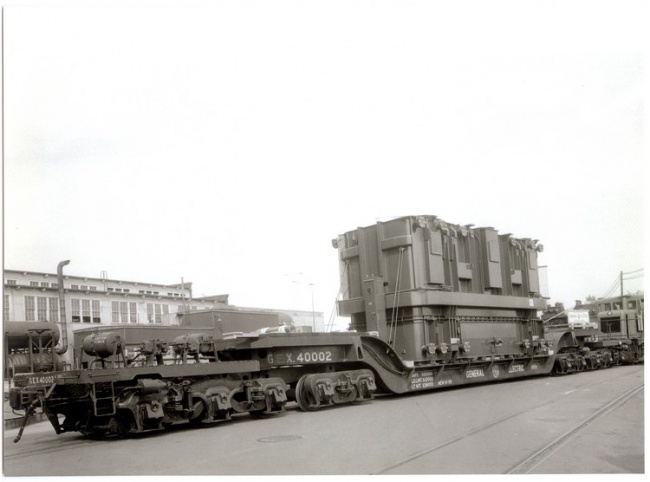

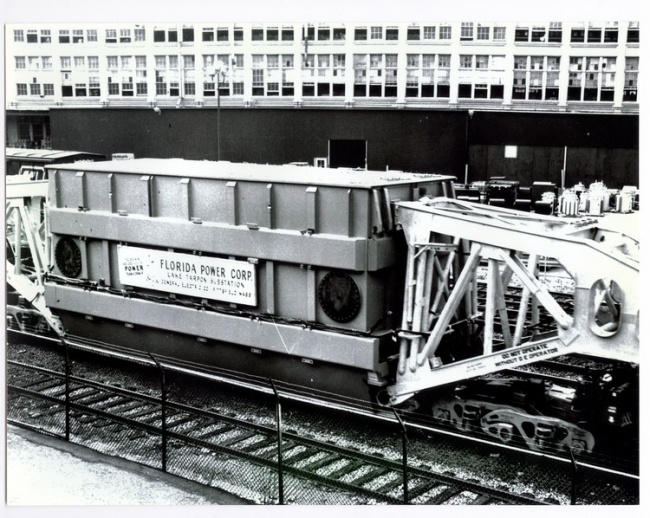

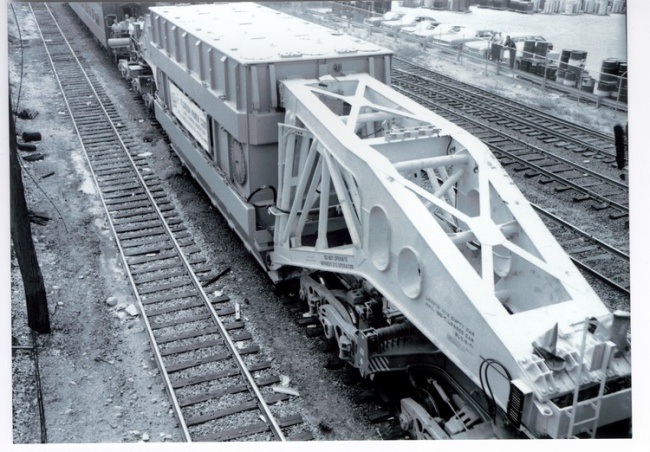

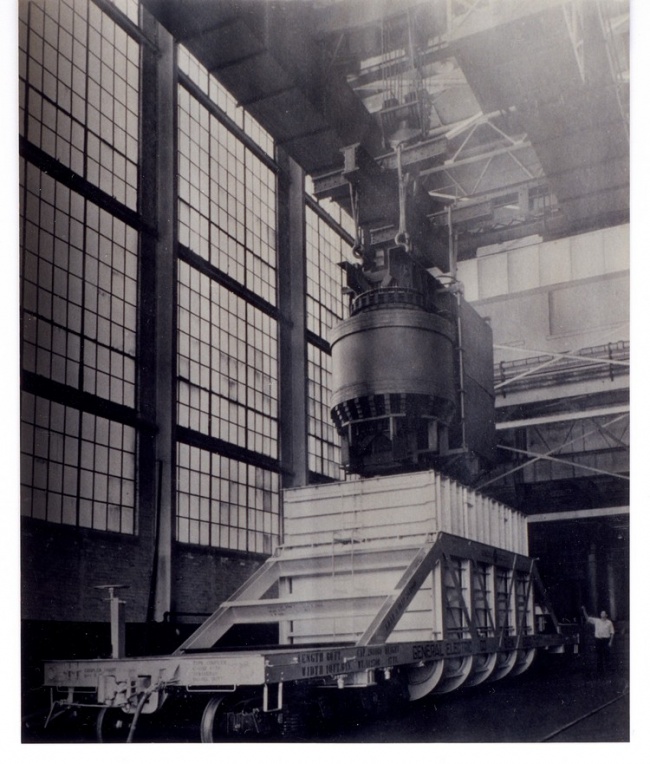

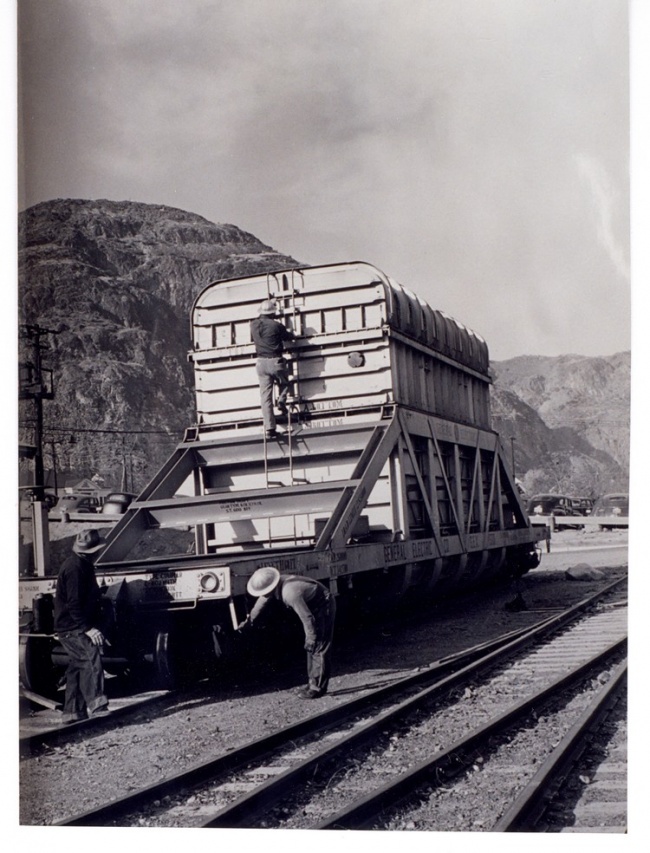

| Janice Calderwood provided information and material related to the Distribution Transformer Operation. Ed Kopf contributed valuable information on the early years of the Apprentice Program, as well as on many other aspects of life in the Pittsfield plant. William Coles provided details of Power House modifications over the years. Sam Sass contributed historical details related to the Stanley Library and other matters. R. Kelly Niederjohn and Stan Wilk provided information on the aspects of shipping huge transformers. | | Janice Calderwood provided information and material related to the Distribution Transformer Operation. Ed Kopf contributed valuable information on the early years of the Apprentice Program, as well as on many other aspects of life in the Pittsfield plant. William Coles provided details of Power House modifications over the years. Sam Sass contributed historical details related to the Stanley Library and other matters. R. Kelly Niederjohn and Stan Wilk provided information on the aspects of shipping huge transformers. |

|

| |

|

| John Anderson contributed information regarding the Empire State Building lightning study, as well as the operation of the High Voltage Laboratory and Projects EHV and UHV. John Benedict contributed photos and other material related to the Building 9 High Voltage Labora- tory. Details relative to lightning arrester development and the operation of the Dufour cold-cathode oscillograph were provided by Tom Carpenter. Finally, much information about the operation of the transformer testing facility was contributed by G.G. ("Pete") Kemp and by Tom Stanfield. | | John Anderson contributed information regarding the Empire State Building lightning study, as well as the operation of the High Voltage Laboratory and Projects EHV and UHV. John Benedict contributed photos and other material related to the Building 9 High Voltage Laboratory. Details relative to lightning arrester development and the operation of the Dufour cold-cathode oscillograph were provided by Tom Carpenter. Finally, much information about the operation of the transformer testing facility was contributed by G.G. ("Pete") Kemp and by Tom Stanfield. |

|

| |

|

| Access to archival material stored in the Pittsfield G.E. plant was provided by Tom Bednarz, William Carter, Jr., and Art Stringer. | | Access to archival material stored in the Pittsfield G.E. plant was provided by Tom Bednarz, William Carter, Jr., and Art Stringer. |

| Line 70: |

Line 72: |

| == Chapter 1: The Early Years == | | == Chapter 1: The Early Years == |

|

| |

|

| "One day Mr. Whittlesey came to Barrington and I told him of my withdrawal from the Pittsburgh company. He asked me to come to Pittsfield and see some of his friends before I embarked anew. I came up to Pittsfield and met two sterling men, the late W.R. Plunkett and the late W.W. Gamwell. Mr. Plunkett called a meeting of businessmen at his residence on East Street. A dozen or so attended this meeting and we discussed the starting of a company to build transformers. Mr. Whittlesey then got subscriptions for $25,000. Two companies were organized. One, 'The Laboratory Company', with a small capital, in which Messrs. Chesney, Kelly and myself were the principle stockholders, and the other, 'The Manufacturing Company'. Mr. Chesney was chosen as the works manager of the manufacturing company and we started in." | | "One day Mr. Whittlesey came to Barrington and I told him of my withdrawal from the Pittsburgh company. He asked me to come to Pittsfield and see some of his friends before I embarked anew. I came up to Pittsfield and met two sterling men, the late W.R. Plunkett and the late W.W. Gamwell. Mr. Plunkett called a meeting of businessmen at his residence on East Street. A dozen or so attended this meeting and we discussed the starting of a company to build transformers. Mr. Whittlesey then got subscriptions for $25,000. Two companies were organized. One, 'The Laboratory Company', with a small capital, in which Messrs. [[Cummings C. Chesney|Chesney]], Kelly and myself were the principle stockholders, and the other, 'The Manufacturing Company'. Mr. Chesney was chosen as the works manager of the manufacturing company and we started in." |

|

| |

|

| William Stanley | | - [[William Stanley|William Stanley]] |

|

| |

|

| The above quotation describes William Stanley's departure from the Westinghouse Company in Pittsburgh, and the subsequent establishment of a transformer manufacturing plant in Pittsfield. Thus began the ninety-six year history of the manufacture of transformers in Pittsfield which ended with the closing of the Large Transformer Operation of General Electric in 1987. | | The above quotation describes [[William Stanley|William Stanley]]'s departure from the Westinghouse Company in Pittsburgh, and the subsequent establishment of a transformer manufacturing plant in Pittsfield. Thus began the ninety-six year history of the manufacture of transformers in Pittsfield which ended with the closing of the Large Transformer Operation of General Electric in 1987. |

|

| |

|

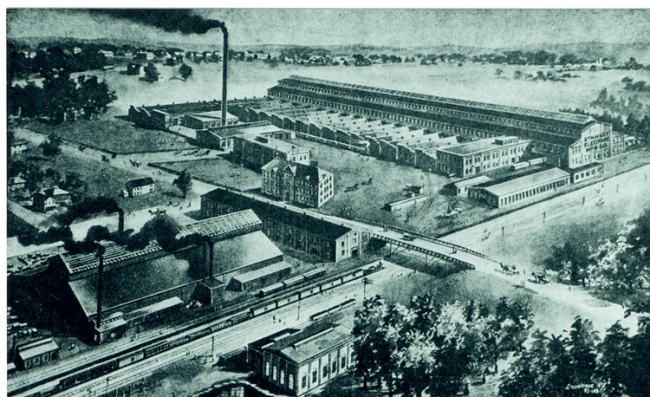

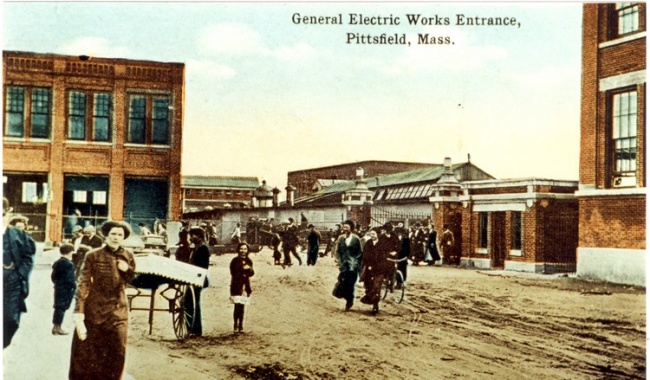

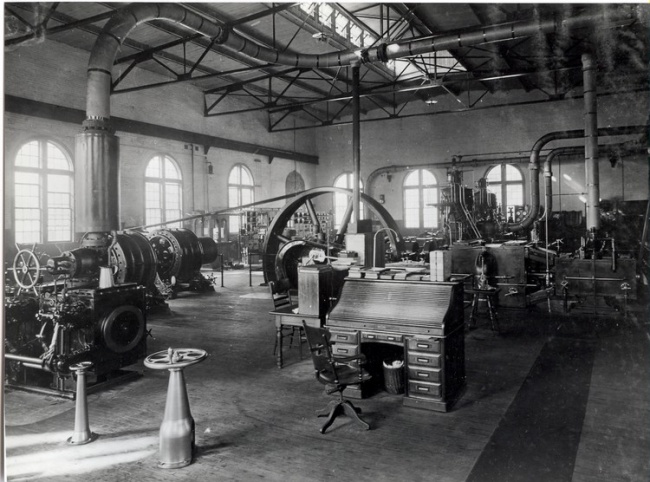

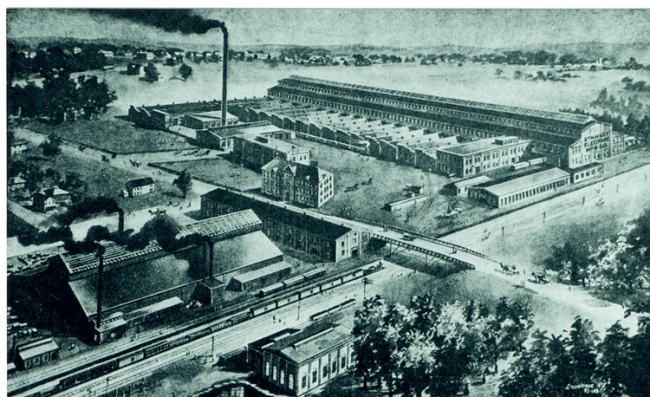

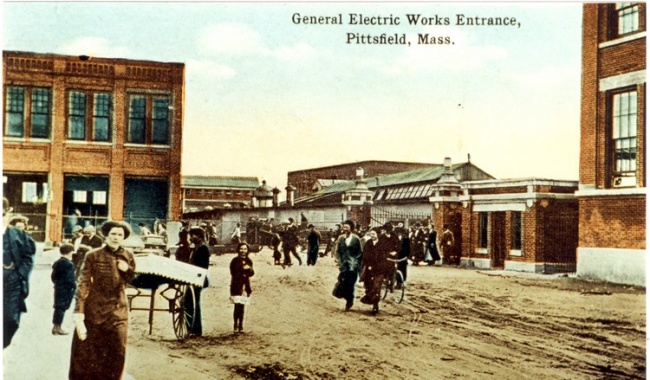

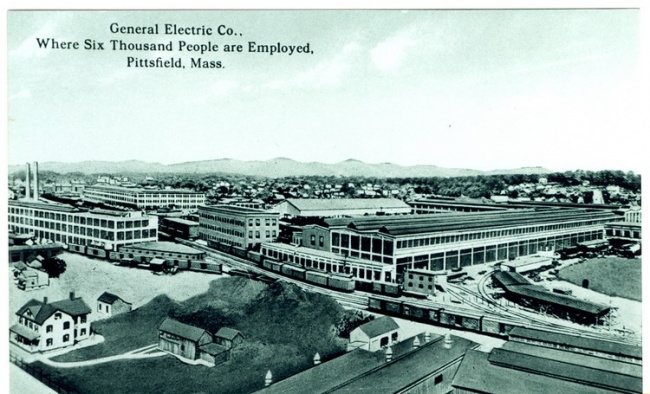

| The Stanley Laboratory Company originated in a building on Cottage Row (now Eagle Street) in Pittsfield, in 1890. The Stanley Electric Manufacturing Company went into operation on Clapp Avenue (now gone) in January of 1891. The Works Engineer was Cummings Chesney and the Shop Superintendent was John Kelman. The first shipment of "S.K.C." (Stanley-Kelly-Chesney) transformers left the shop on April 1, 1891. | | The Stanley Laboratory Company originated in a building on Cottage Row (now Eagle Street) in Pittsfield, in 1890. The Stanley Electric Manufacturing Company went into operation on Clapp Avenue (now gone) in January of 1891. The Works Engineer was Cummings Chesney and the Shop Superintendent was John Kelman. The first shipment of "S.K.C." (Stanley-Kelly-Chesney) transformers left the shop on April 1, 1891. |

| Line 104: |

Line 106: |

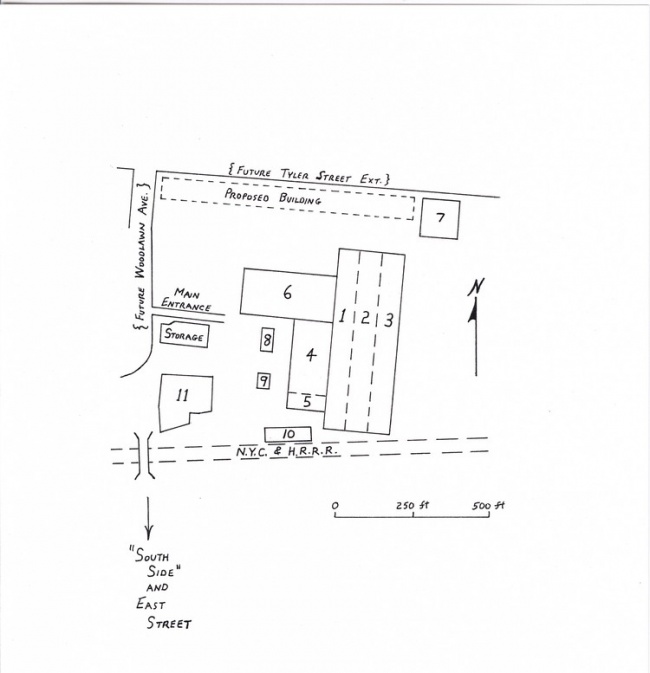

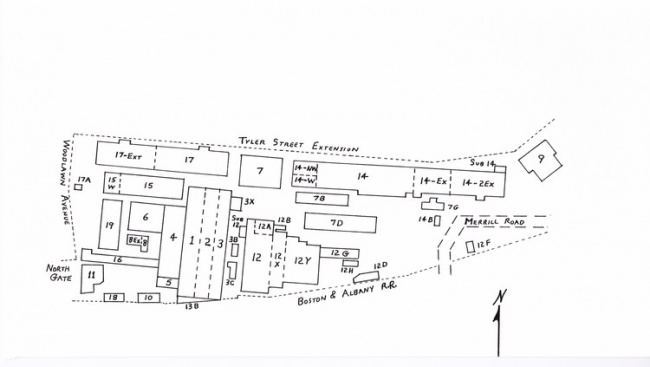

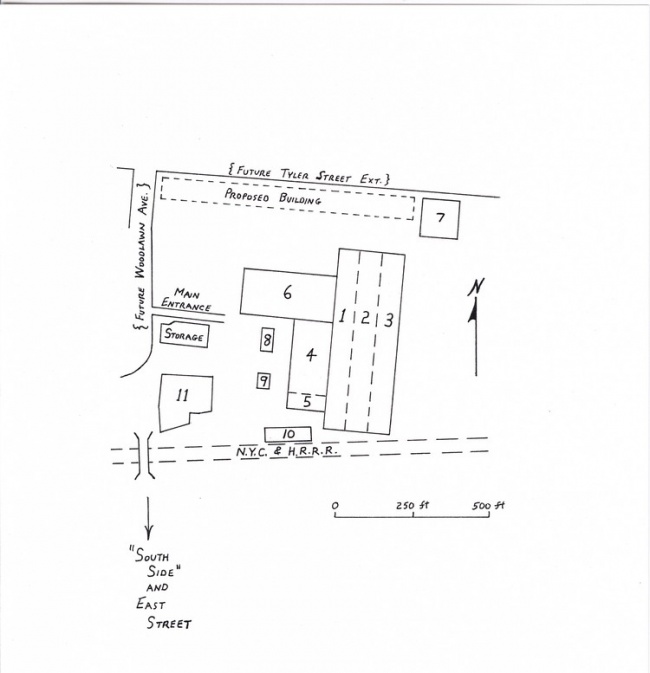

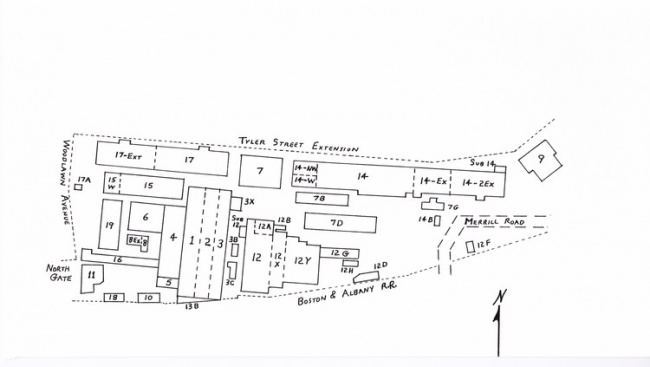

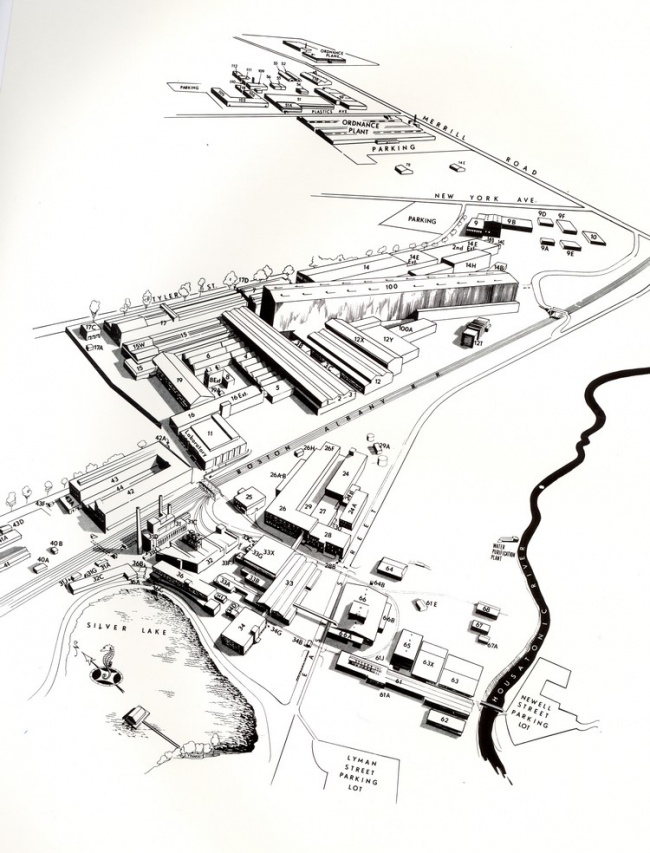

| The identified buildings served the following functions in 1908: | | The identified buildings served the following functions in 1908: |

|

| |

|

| <u>Buildings 1-2-3</u>

| | === Buildings 1-2-3 === |

|

| |

|

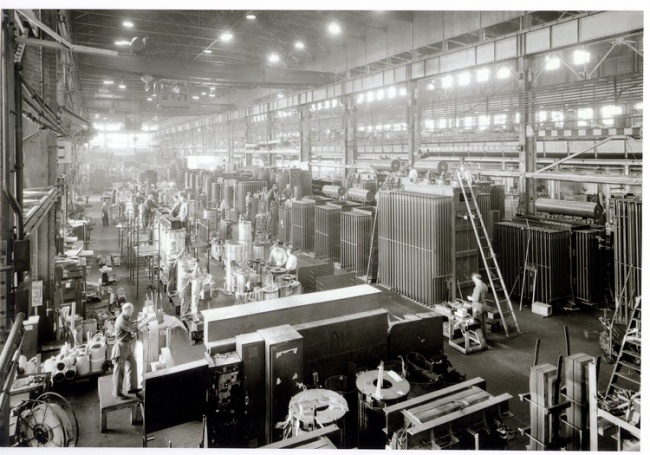

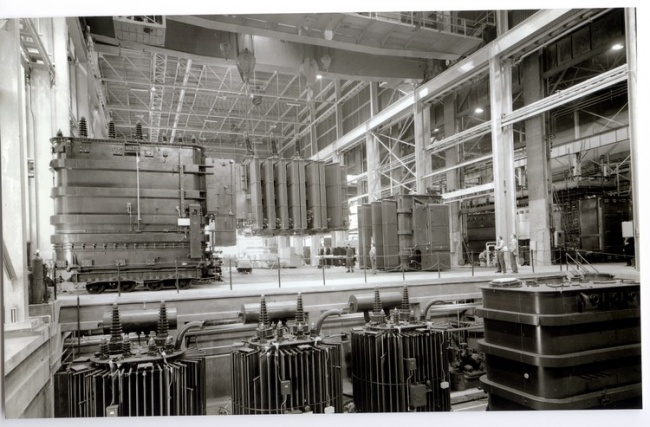

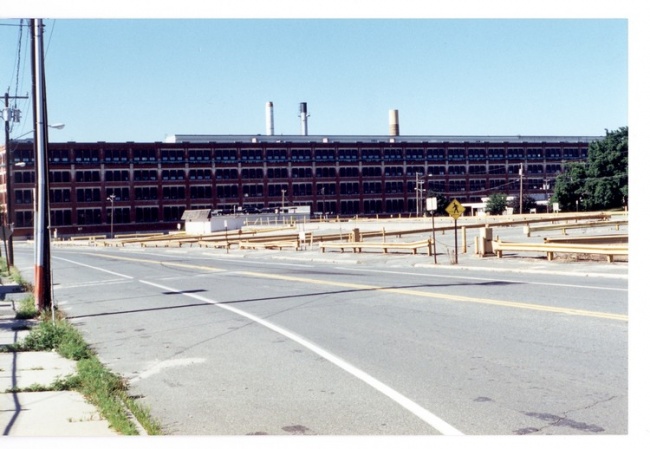

| These were the main transformer assembly and testing bays. Building 1 was constructed in 1900, and Buildings 2 and 3 were added around the time that the plant became a part of G.E. These buildings still exist today. | | These were the main transformer assembly and testing bays. Building 1 was constructed in 1900, and Buildings 2 and 3 were added around the time that the plant became a part of G.E. These buildings still exist today. |

|

| |

|

| <u>Building 4</u>

| | === Building 4 === |

|

| |

|

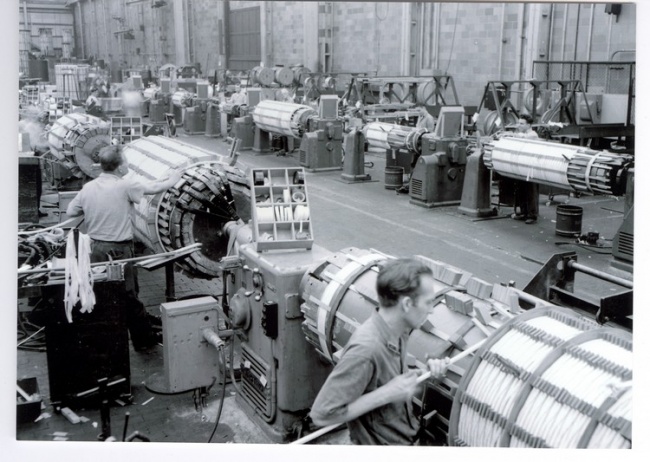

| This was the main winding area for the larger sizes of transformers. It also still exists. This was also the assembly area for small types of transformers. | | This was the main winding area for the larger sizes of transformers. It also still exists. This was also the assembly area for small types of transformers. |

|

| |

|

| <u>Building 5.</u>

| | === Building 5 === |

|

| |

|

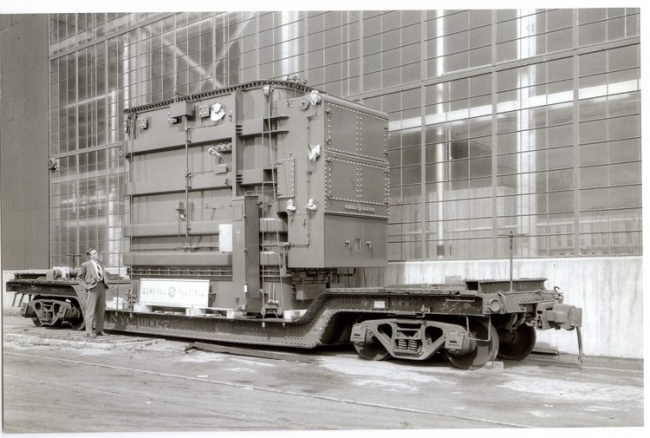

| This was the main shipping area. It was served by a railroad siding running along its south side; this siding also ran through the south end of the Building 1-2-3 complex. This building eventually housed offices and the "copper shop", and still exists. | | This was the main shipping area. It was served by a railroad siding running along its south side; this siding also ran through the south end of the Building 1-2-3 complex. This building eventually housed offices and the "copper shop", and still exists. |

|

| |

|

| <u>Building 6</u>

| | === Building 6 === |

|

| |

|

| This was the area in which the various types of insulation (such as pressboard, etc.) needed in the transformers was prepared. It still exists. | | This was the area in which the various types of insulation (such as pressboard, etc.) needed in the transformers was prepared. It still exists. |

|

| |

|

| <u>Building 7</u>

| | === Building 7 === |

|

| |

|

| This was where the thin laminations of steel needed to build up the magnetic cores of the transformers were fabricated. This building served several other functions in later years. It still stands, but is somewhat derelict. | | This was where the thin laminations of steel needed to build up the magnetic cores of the transformers were fabricated. This building served several other functions in later years. It still stands, but is somewhat derelict. |

|

| |

|

| <u>Building 8</u>

| | === Building 8 === |

|

| |

|

| This was the Laboratory building where the development of transformer insulation materials, and the high voltage testing of same, was carried on. It still stands, but is also somewhat derelict. | | This was the Laboratory building where the development of transformer insulation materials, and the high voltage testing of same, was carried on. It still stands, but is also somewhat derelict. |

|

| |

|

| <u>Building 9</u>

| | === Building 9 === |

|

| |

|

| This no longer exists; it was a storage facility for the oils used in transformers for insulation and cooling. | | This no longer exists; it was a storage facility for the oils used in transformers for insulation and cooling. |

|

| |

|

| <u>Building 10</u>

| | === Building 10 === |

|

| |

|

| This was identified as a Carpenter and Pattern Shop, and no Longer exists. | | This was identified as a Carpenter and Pattern Shop, and no Longer exists. |

|

| |

|

| <u>Building 11</u>

| | === Building 11 === |

|

| |

|

| This was the Brass Foundry and Tank Shop, for the production of brass electrical fittings and the fabrication of the iron tanks which held the working parts of the transformers. The site is presently occupied by a new Building 11 dating from the 1960's. | | This was the Brass Foundry and Tank Shop, for the production of brass electrical fittings and the fabrication of the iron tanks which held the working parts of the transformers. The site is presently occupied by a new Building 11 dating from the 1960's. |

| Line 178: |

Line 180: |

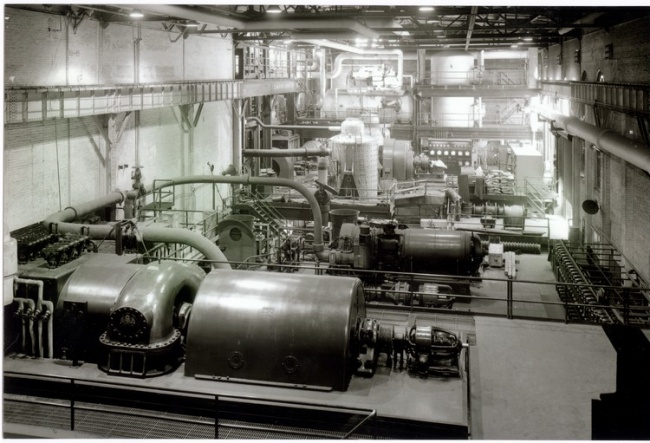

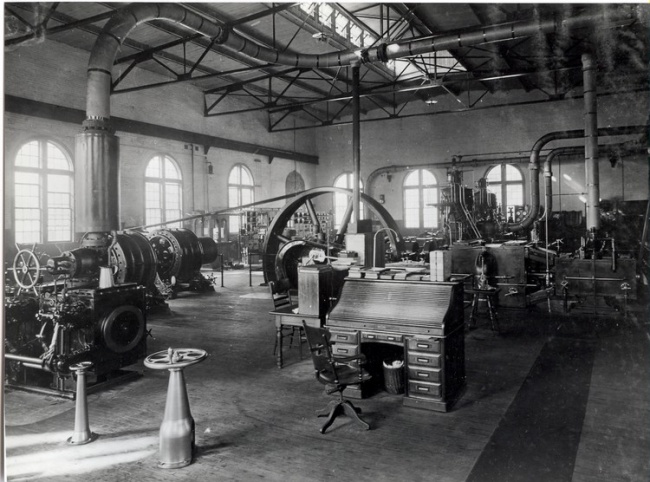

| An interesting aspect of the electric power system in the Morningside plant is that it was not the standard three-phase type of power which is universally used now. The generation and distribution was via a system known as "two-phase". | | An interesting aspect of the electric power system in the Morningside plant is that it was not the standard three-phase type of power which is universally used now. The generation and distribution was via a system known as "two-phase". |

|

| |

|

| William Stanley designed and built a great deal of two-phase equipment during the 1890's, partly because of a belief in its superiority over three-phase, but also to avoid patent infringement problems with General Electric and Westinghouse who both used the three-phase system. | | [[William Stanley|William Stanley]] designed and built a great deal of two-phase equipment during the 1890's, partly because of a belief in its superiority over three-phase, but also to avoid patent infringement problems with [[General Electric (GE)|General Electric]] and Westinghouse who both used the three-phase system. |

|

| |

|

| In fact, three-phase is decidedly superior for power distribution purposes. Thus, the old two-phase systems have gradually faded out of existence. However, two-phase power was so firmly entrenched in the Pittsfield plant that remnants of it still exist today! This has to do with the existence of old two-phase motors which have never been replaced. | | In fact, three-phase is decidedly superior for power distribution purposes. Thus, the old two-phase systems have gradually faded out of existence. However, two-phase power was so firmly entrenched in the Pittsfield plant that remnants of it still exist today! This has to do with the existence of old two-phase motors which have never been replaced. |

| Line 279: |

Line 281: |

| *An addition (known as "17Ext") was made to <u>Building 17</u>, located near the corner of Tyler Street and Woodlawn Avenue. Originally built in 1910, Building 17 had become the Tank Shop where steel transformer tanks were fabricated. The original Tank Shop had been on the site of the present Building 11. | | *An addition (known as "17Ext") was made to <u>Building 17</u>, located near the corner of Tyler Street and Woodlawn Avenue. Originally built in 1910, Building 17 had become the Tank Shop where steel transformer tanks were fabricated. The original Tank Shop had been on the site of the present Building 11. |

|

| |

|

| *<u>William Stanley</u> died in Great Barrington. | | *[[William Stanley|William Stanley]] died in Great Barrington. |

|

| |

|

| *G.E. sponsored an elaborate production of Gilbert and Sullivan's "The Mikado", at the <u>Colonial Theatre</u> on South Street in Pittsfield. | | *G.E. sponsored an elaborate production of Gilbert and Sullivan's "The Mikado", at the <u>Colonial Theatre</u> on South Street in Pittsfield. |

| Line 389: |

Line 391: |

| 1927: | | 1927: |

|

| |

|

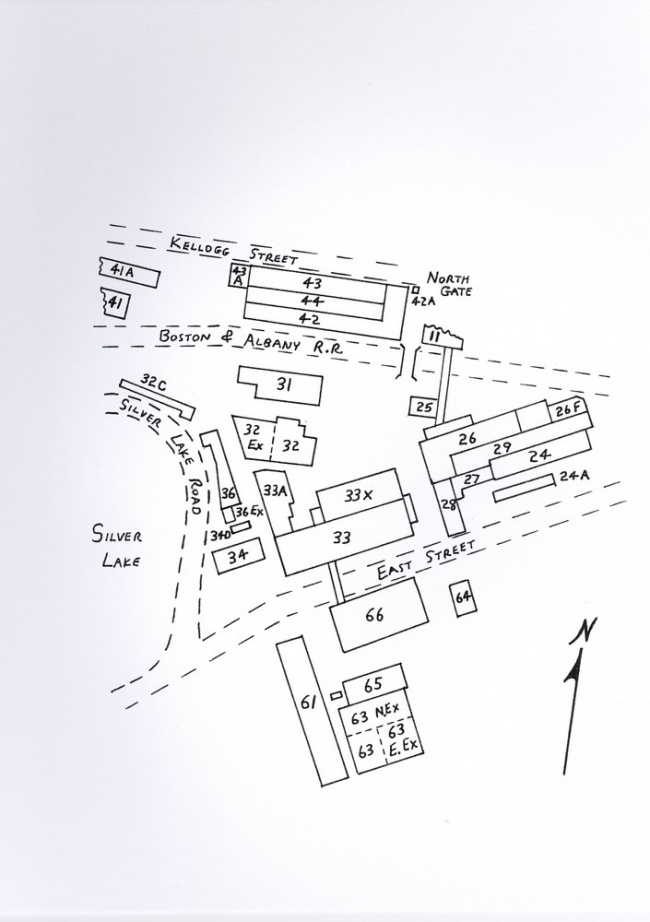

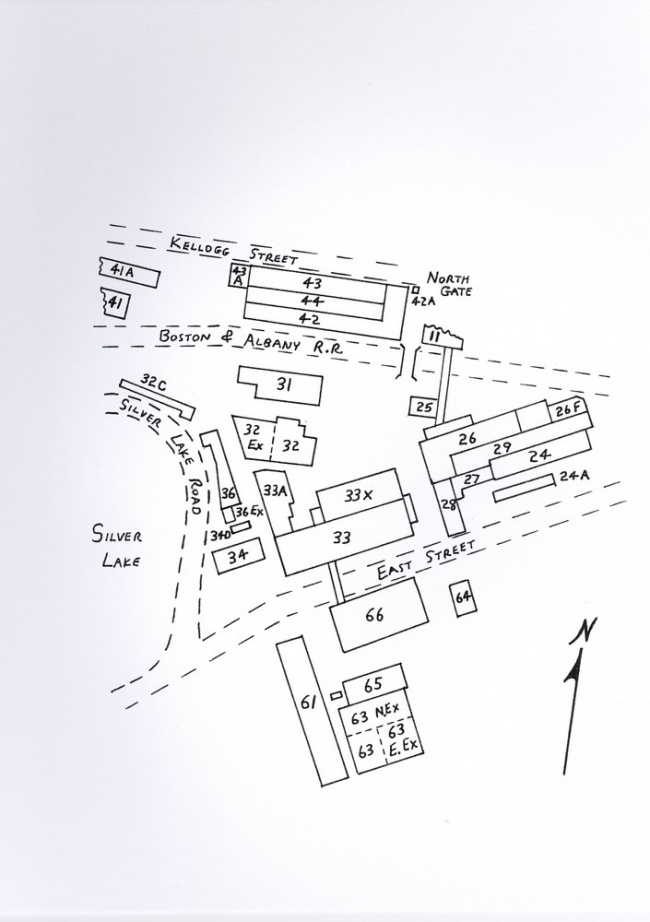

| *<u>Capacitors</u> were being manufactured in a part of Building 42. | | *[[Capacitors|Capacitors]] were being manufactured in a part of Building 42. |

|

| |

|

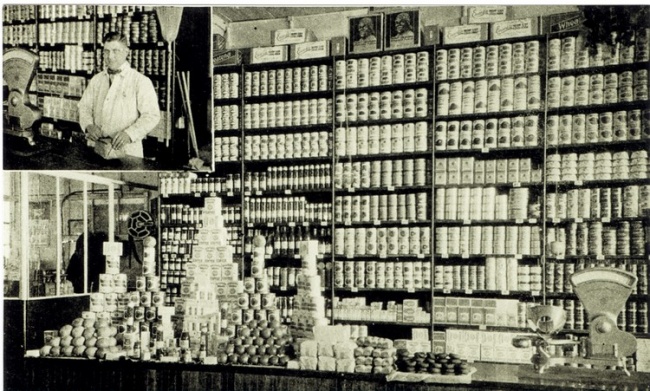

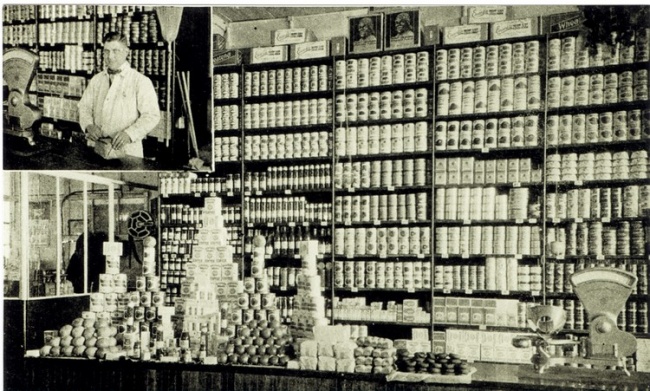

| *The <u>Works Restaurant</u> was now operating in a section of Building 43, known as "43B". A cafeteria for the "South Side" was operating in Building 27. | | *The <u>Works Restaurant</u> was now operating in a section of Building 43, known as "43B". A cafeteria for the "South Side" was operating in Building 27. |

| Line 403: |

Line 405: |

| Apprentices attended one two-hour class each working day. During the first year of the program, they learned how to operate every one of the machines in the shop. Then, they were sent to areas related to their particular line of interest: drafting, tool-making, pattern-making, maintenance, or engineering. There were both three and four year courses, and an entrance exam was mandatory. | | Apprentices attended one two-hour class each working day. During the first year of the program, they learned how to operate every one of the machines in the shop. Then, they were sent to areas related to their particular line of interest: drafting, tool-making, pattern-making, maintenance, or engineering. There were both three and four year courses, and an entrance exam was mandatory. |

|

| |

|

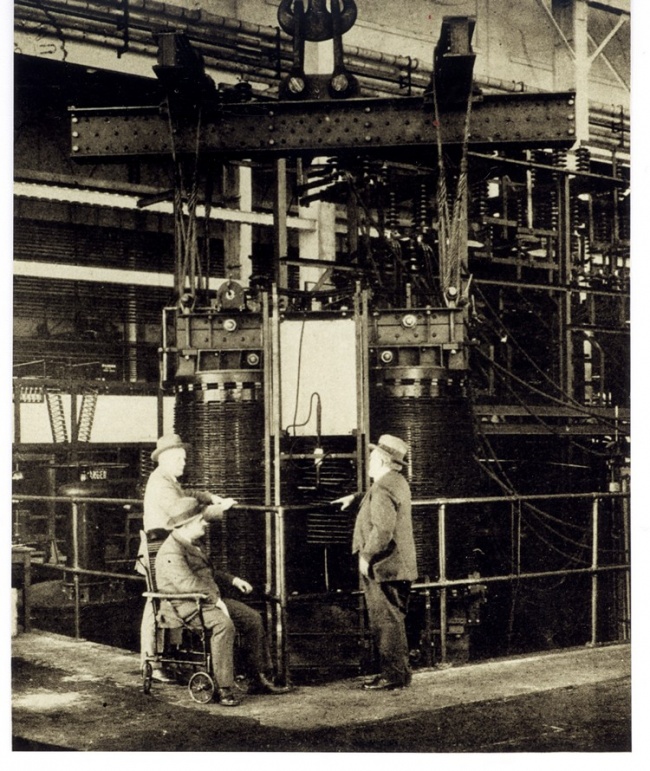

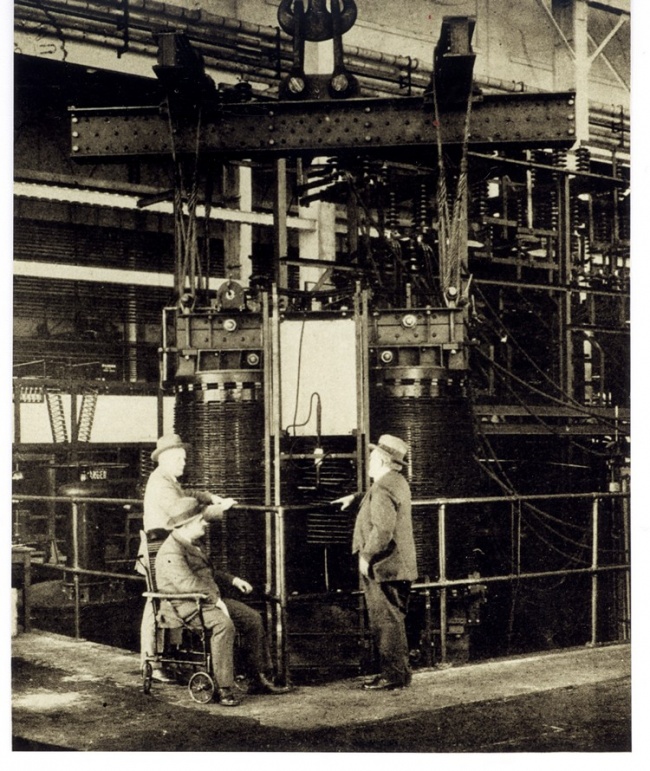

| [[Image:Blalock - page 23 (bot).jpg|thumb|center|650px|Works Manager Cummings C. Chesney, along with Guiseppe Faccioli (in wheelchair) and W.S. Moody, inspect the largest single-phase transformer built as of 1926 (water-cooled, 60-cycles, 28,886-Kva, 100 tons for the Wallenpaupack Substation of the Pennsylvania Power and Light system; the three-phase bank of which it was to be a part was rated for 220-Kv to 66-Kv with an 11-Kv tertiary winding), G.E. Current News, January, 1926]] | | [[Image:Blalock - page 28.jpg|thumb|center|650px|Works Manager Cummings C. Chesney, along with Guiseppe Faccioli (in wheelchair) and W.S. Moody, inspect the largest single-phase transformer built as of 1926 (water-cooled, 60-cycles, 28,886-Kva, 100 tons for the Wallenpaupack Substation of the Pennsylvania Power and Light system; the three-phase bank of which it was to be a part was rated for 220-Kv to 66-Kv with an 11-Kv tertiary winding), G.E. Current News, January, 1926]] |

|

| |

|

| Apprentices were able to obtain experience working in any of the different departments in the plant: principally Power Transformer, Distribution Transformer, Regulators, Load Ratio Control, Foundry, Tool Room, Lightning Arresters, and Bushings. | | Apprentices were able to obtain experience working in any of the different departments in the plant: principally Power Transformer, Distribution Transformer, Regulators, Load Ratio Control, Foundry, Tool Room, Lightning Arresters, and Bushings. |

| Line 415: |

Line 417: |

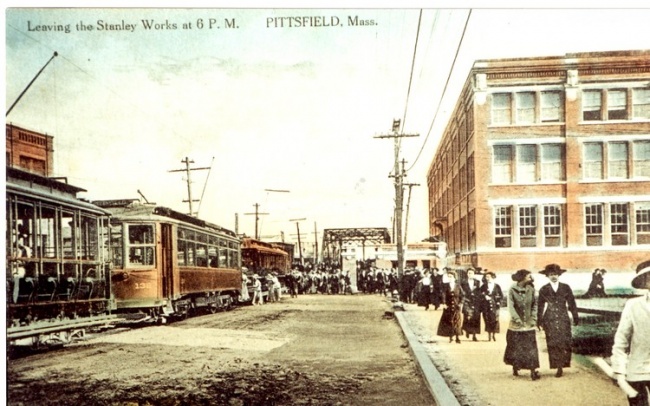

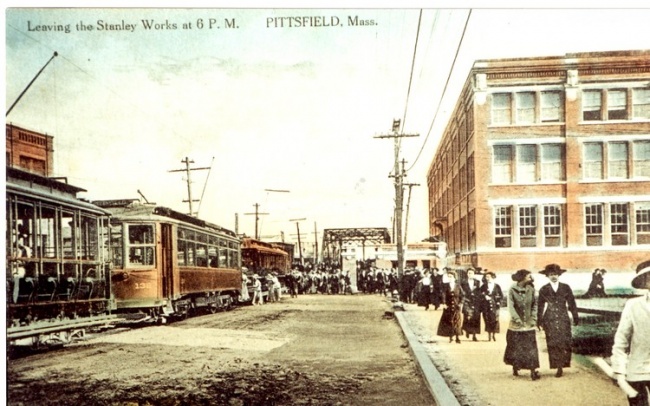

| Other recollections of Mr. Kopf's include the fact that two small steam locomotives were used to haul materials around the plant in those days. Tracks ran up the hill from South Gate (at East Street), over the railroad, and out North Gate onto Woodlawn Avenue; then back into the plant at Building 17 and on to the Tank Shop (Building 14). In the winter, when ice and snow were on the tracks coming up from South Gate, men had to run ahead of the locomotive with buckets of sand to throw on the tracks for traction! Sometimes, with big loads, both locomotives had to be used running in tandem. | | Other recollections of Mr. Kopf's include the fact that two small steam locomotives were used to haul materials around the plant in those days. Tracks ran up the hill from South Gate (at East Street), over the railroad, and out North Gate onto Woodlawn Avenue; then back into the plant at Building 17 and on to the Tank Shop (Building 14). In the winter, when ice and snow were on the tracks coming up from South Gate, men had to run ahead of the locomotive with buckets of sand to throw on the tracks for traction! Sometimes, with big loads, both locomotives had to be used running in tandem. |

|

| |

|

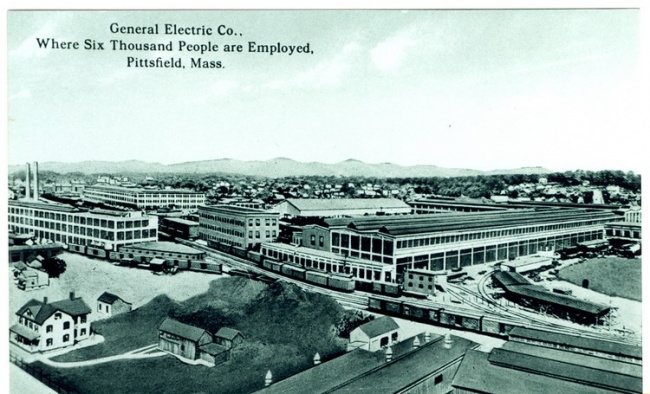

| Also, during that era, the twelve to fifteen thousand employees in the Pittsfield plant received their pay in cash (no checks). Money was picked up at the First Agricultural Bank in Pittsfield and brought to the plant in a large safe mounted on a flatbed truck. This was a battery-operated truck, and only enough charge was put into the batteries to make the trip to the bank and back again! Armed guards | | Also, during that era, the twelve to fifteen thousand employees in the Pittsfield plant received their pay in cash (no checks). Money was picked up at the First Agricultural Bank in Pittsfield and brought to the plant in a large safe mounted on a flatbed truck. This was a battery-operated truck, and only enough charge was put into the batteries to make the trip to the bank and back again! Armed guards from the plant accompanied the truck, and additional armed guards from the bank were on hand for the loading of the money into the truck. |

| | |

| from the plant accompanied the truck, and additional armed guards from the bank were on hand for the loading of the money into the truck. | |

|

| |

|

| The truck was driven into a freight elevator in Building 42 and taken up to the Payroll Department. Each department in the plant had a fold-up wire cage which was set up at a designated spot on pay day. The money was distributed to these various locations by other trucks. At each stop, the money and a payroll clerk were left in the cage. Pay envelopes were arranged by clock number, and it took only ten or fifteen minutes in each department to distribute all of the pay. | | The truck was driven into a freight elevator in Building 42 and taken up to the Payroll Department. Each department in the plant had a fold-up wire cage which was set up at a designated spot on pay day. The money was distributed to these various locations by other trucks. At each stop, the money and a payroll clerk were left in the cage. Pay envelopes were arranged by clock number, and it took only ten or fifteen minutes in each department to distribute all of the pay. |

| Line 451: |

Line 451: |

| *The first commercial <u>Impulse Test</u> was performed on a transformer. This test simulates the effect of lightning-related surges which the transformer may be subjected to in service and demonstrates that the transformer insulation will withstand such mistreatment. | | *The first commercial <u>Impulse Test</u> was performed on a transformer. This test simulates the effect of lightning-related surges which the transformer may be subjected to in service and demonstrates that the transformer insulation will withstand such mistreatment. |

|

| |

|

| *<u>Giuseppe Faccioli</u> retires due to ill health. | | *[[Archives:Papers of G. Faccioli|Giuseppe Faccioli]] retires due to ill health. |

|

| |

|

| *<u>Cummings C. Chesney</u> retires. | | *[[Cummings C. Chesney|Cummings C. Chesney]] retires. |

|

| |

|

| *<u>Building 62</u> is built south of East Street. This functioned as the Gas Plant, producing various types of bottled gas for use in production processes. | | *<u>Building 62</u> is built south of East Street. This functioned as the Gas Plant, producing various types of bottled gas for use in production processes. |

| Line 485: |

Line 485: |

| Guglielmo Camilli was a native of Rome, Italy; he received his engineering degree from the Royal Polytechnic School of Turin in 1922. In 1926, he began his career with General Electric as a Development Engineer in Pittsfield. | | Guglielmo Camilli was a native of Rome, Italy; he received his engineering degree from the Royal Polytechnic School of Turin in 1922. In 1926, he began his career with General Electric as a Development Engineer in Pittsfield. |

|

| |

|

| In 1956, he was named Supervisor of Power Transformer Advance Product Engineering. By 1958, he had received a total of fifty-five patents, more than anyone else in the General Electric Company at the time. He was twice the recipient of the Coffin Award, the highest employee honor bestowed by General Electric. He was the author of a book on the subject of transformer engineering, and authored many technical papers throughout his career. | | In 1956, he was named Supervisor of Power Transformer Advance Product Engineering. By 1958, he had received a total of fifty-five patents, more than anyone else in the [[General Electric (GE)|General Electric Company]] at the time. He was twice the recipient of the Coffin Award, the highest employee honor bestowed by General Electric. He was the author of a book on the subject of transformer engineering, and authored many technical papers throughout his career. |

|

| |

|

| Camilli was an avid amateur astronomer. He ground his own lenses and built his own telescopes. He was a member of the volunteer Pittsfield G.E. Speakers Bureau; as such, he presented a very popular talk around the country which was called "A Trip through the Universe". He predicted that the United States would reach the moon by 1967 (not far off!). He also used his immense knowledge of transformer insulation structures and cooling methods to design a "transformer for use on the moon" in 1955! He operated his own personal observatory at his home on East New Lenox Road in Pittsfield. | | Camilli was an avid amateur astronomer. He ground his own lenses and built his own telescopes. He was a member of the volunteer Pittsfield G.E. Speakers Bureau; as such, he presented a very popular talk around the country which was called "A Trip through the Universe". He predicted that the United States would reach the moon by 1967 (not far off!). He also used his immense knowledge of transformer insulation structures and cooling methods to design a "transformer for use on the moon" in 1955! He operated his own personal observatory at his home on East New Lenox Road in Pittsfield. |

| Line 493: |

Line 493: |

| === Cummings C. Chesney === | | === Cummings C. Chesney === |

|

| |

|

| C.C. Chesney, a native of Pennsylvania, was born in 1863. Following his graduation from Pennsylvania State College in 1885, he taught mathematics and chemistry until becoming associated with William Stanley in 1888, in Great Barrington, Mass., as a chemist and engineer. | | [[Cummings C. Chesney|C.C. Chesney]], a native of Pennsylvania, was born in 1863. Following his graduation from Pennsylvania State College in 1885, he taught mathematics and chemistry until becoming associated with [[William Stanley|William Stanley]] in 1888, in Great Barrington, Mass., as a chemist and engineer. |

|

| |

|

| He followed Stanley to the United States Electric Lighting Company in Newark, New Jersey (a subsidiary of the Westinghouse Company) in 1889. He then became associated with the Stanley Electrical Manufacturing Company in Pittsfield as an electrical engineer in 1891. He was the "C" in the S.K.C. system marketed by Stanley. | | He followed Stanley to the United States Electric Lighting Company in Newark, New Jersey (a subsidiary of the Westinghouse Company) in 1889. He then became associated with the Stanley Electrical Manufacturing Company in Pittsfield as an electrical engineer in 1891. He was the "C" in the S.K.C. system marketed by Stanley. |

| Line 503: |

Line 503: |

| Chesney was very active in local business activities as well as civic affairs. He was active in the Boys' Club of Pittsfield, and was a member of the Chamber of Commerce there. | | Chesney was very active in local business activities as well as civic affairs. He was active in the Boys' Club of Pittsfield, and was a member of the Chamber of Commerce there. |

|

| |

|

| In 1921, he received the Edison Medal from the American Institute of Electrical Engineers, and he served as President of that organization from 1926 to 1927. The Edison Medal is the highest award given to an electrical engineer, and is for meritorious achievements in electrical science, engineering and art. | | In 1921, he received the [[IEEE Edison Medal|Edison Medal]] from the [[AIEE History 1884-1963|American Institute of Electrical Engineers]], and he served as [[Presidents of the American Institute of Electrical Engineers (AIEE)|President of that organization from 1926 to 1927]]. The Edison Medal is the highest award given to an electrical engineer, and is for meritorious achievements in electrical science, engineering and art. |

|

| |

|

| Cummings Chesney retired in 1930 and died in 1947. He was survived by his widow, Elizabeth, four daughters, a son, and eleven grandchildren. | | Cummings Chesney retired in 1930 and died in 1947. He was survived by his widow, Elizabeth, four daughters, a son, and eleven grandchildren. |

| Line 509: |

Line 509: |

| === Giuseppe Faccioli === | | === Giuseppe Faccioli === |

|

| |

|

| Giuseppe Faccioli was born in Rome, Italy in 1877 and graduated with high honors from the Institute of Technology in Milan in 1899 as a mechanical and electrical engineer. He came to the United States in 1902 and obtained a position with the New York Edison Company (the ancestor of Consolidated Edison in New York City). One year later, however, he transferred to the employ of the Interborough Rapid Transit Company, the builders of the first subway system (the IRT) in New York City. | | [[Archives:Papers of G. Faccioli|Giuseppe Faccioli]] was born in Rome, Italy in 1877 and graduated with high honors from the Institute of Technology in Milan in 1899 as a mechanical and electrical engineer. He came to the United States in 1902 and obtained a position with the New York Edison Company (the ancestor of Consolidated Edison in New York City). One year later, however, he transferred to the employ of the Interborough Rapid Transit Company, the builders of the first subway system (the IRT) in New York City. |

|

| |

|

| Then, in 1904, he went to work for the Crocker-Wheeler Company in Ampere, New Jersey (near East Orange). Crocker-Wheeler had been building rotating electrical machines for the Stanley Company and, as a result, he came into contact with William Stanley. This led to his joining Stanley in Great Barrington (by this time, the Stanley Company in Pittsfield was a subsidiary of General Electric, and Stanley himself had gone back to Great Barrington to engage in other ventures). | | Then, in 1904, he went to work for the Crocker-Wheeler Company in Ampere, New Jersey (near East Orange). Crocker-Wheeler had been building rotating electrical machines for the Stanley Company and, as a result, he came into contact with William Stanley. This led to his joining Stanley in Great Barrington (by this time, the Stanley Company in Pittsfield was a subsidiary of General Electric, and Stanley himself had gone back to Great Barrington to engage in other ventures). |

| Line 529: |

Line 529: |

| In 1922, he devised the 1,000,000 volt three-phase arc which remained a mainstay of public demonstrations for the next fifty years or so. | | In 1922, he devised the 1,000,000 volt three-phase arc which remained a mainstay of public demonstrations for the next fifty years or so. |

|

| |

|

| He was also involved in the development of equipment such as high current testing transformers, cable testing apparatus, x-ray transformers, high frequency transformers, power and filament transformers for vacuum tube rectifiers, and air-blast type power transformers for use by the Interborough Rapid Transit Company of New York City (builders of the first subway system there). | | He was also involved in the development of equipment such as high current testing transformers, cable testing apparatus, x-ray transformers, high frequency transformers, power and filament transformers for [[Electron (or Vacuum) Tubes|vacuum tube]] rectifiers, and air-blast type power transformers for use by the Interborough Rapid Transit Company of New York City (builders of the first subway system there). |

|

| |

|

| In later years, he was also intimately involved with the design of impulse generators for laboratory testing with simulated lightning surges. | | In later years, he was also intimately involved with the design of impulse generators for laboratory testing with simulated lightning surges. |

| Line 541: |

Line 541: |

| He received the appointment of Manager, Laboratory-Engineering Department in 1952, and, in 1953, was named as the Consultant of Professional Employee Relations for all technical employees in the Engineering Services Division of the General Electric Company. | | He received the appointment of Manager, Laboratory-Engineering Department in 1952, and, in 1953, was named as the Consultant of Professional Employee Relations for all technical employees in the Engineering Services Division of the General Electric Company. |

|

| |

|

| He originated and supervised the lightning investigation at the Empire State Building which yielded .a vast amount of valuable data on natural lightning. Also, under his direction, 10,000,000 volt discharges were produced by impulse generators at the 1939 New York World's Fair, and the new High Voltage Laboratory building (Building 9) was opened in Pittsfield in 1949. | | He originated and supervised the lightning investigation at the Empire State Building which yielded a vast amount of valuable data on natural lightning. Also, under his direction, 10,000,000 volt discharges were produced by impulse generators at the 1939 New York World's Fair, and the new High Voltage Laboratory building (Building 9) was opened in Pittsfield in 1949. |

|

| |

|

| Dr. McEachron was a recognized authority on lightning, world-wide. He was often called upon to testify in cases of lightning-caused injuries and damage. In 1940, he coauthored the book "Playing with Lightning", and, in 1948, he wrote the article "Lightning and Lightning Protection" for inclusion in the Encyclopedia Britannica. He was also the author of many technical papers on the subject of lightning and related topics. | | Dr. McEachron was a recognized authority on lightning, world-wide. He was often called upon to testify in cases of lightning-caused injuries and damage. In 1940, he coauthored the book "Playing with Lightning", and, in 1948, he wrote the article "Lightning and Lightning Protection" for inclusion in the Encyclopedia Britannica. He was also the author of many technical papers on the subject of lightning and related topics. |

| Line 629: |

Line 629: |

| *An unfortunate record was set by the occurrence of seventy-five <u>lost-time accidents</u> for the year. | | *An unfortunate record was set by the occurrence of seventy-five <u>lost-time accidents</u> for the year. |

|

| |

|

| <u>Pyranol</u>

| | === Pyranol === |

|

| |

|

| Also, in 1936, thirty Pyranol network transformers were built for the New York and Queens Electric Light and Power Company in New York City. | | Also, in 1936, thirty Pyranol network transformers were built for the New York and Queens Electric Light and Power Company in New York City. |

| Line 689: |

Line 689: |

| *The Capitol Theatre in Pittsfield was pre- viewing the new film <u>"Edison, The Man"</u>. | | *The Capitol Theatre in Pittsfield was pre- viewing the new film <u>"Edison, The Man"</u>. |

|

| |

|

| <u>World War II</u>

| | === World War II === |

|

| |

|

| In the interest of national security, nothing was published in the Pittsfield G.E. News regarding any involvement in technical activities related to the war effort, on the part of the Pittsfield G.E. plant. | | In the interest of national security, nothing was published in the Pittsfield G.E. News regarding any involvement in technical activities related to the war effort, on the part of the Pittsfield G.E. plant. |

|

| |

|

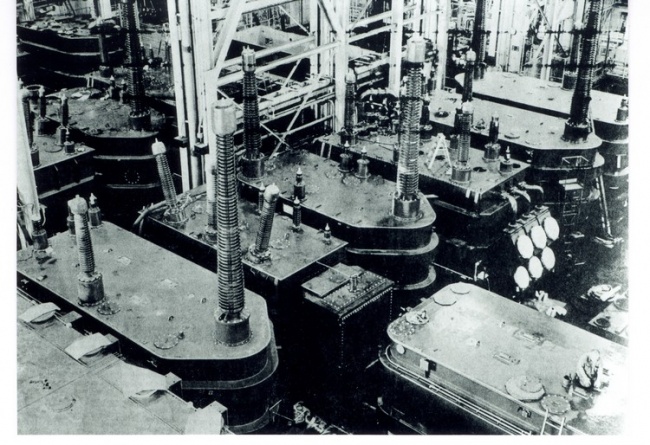

| However, Harry Mason, a former Design Engineer in the Pittsfield transformer operation, has some interesting recollections of this era. Most notably, he was involved in a special project which included the design and manufacture of a large quantity of special transformers for use in the Manhattan Project, which led to the development of the atomic bomb. | | However, Harry Mason, a former Design Engineer in the Pittsfield transformer operation, has some interesting recollections of this era. Most notably, he was involved in a special project which included the design and manufacture of a large quantity of special transformers for use in the [[Manhattan Project|Manhattan Project]], which led to the development of the atomic bomb. |

|

| |

|

| These were rectifier transformers which were shipped to Oak Ridge, Tennessee. They were used in conjunction with rectifiers to produce direct current needed to accelerate uranium ions through a strong magnetic field. This would then separate fissionable U235 from U238. | | These were rectifier transformers which were shipped to Oak Ridge, Tennessee. They were used in conjunction with rectifiers to produce direct current needed to accelerate uranium ions through a strong magnetic field. This would then separate fissionable U235 from U238. |

| Line 727: |

Line 727: |

| *The Pittsfield plant <u>guards were armed</u>! | | *The Pittsfield plant <u>guards were armed</u>! |

|

| |

|

| <u>The Story of the Silver Transformers</u>

| | === The Story of the Silver Transformers === |

|

| |

|

| In 1942, due to a critical shortage of copper, twelve transformers were built at the Pittsfield plant which had silver windings! | | In 1942, due to a critical shortage of copper, twelve transformers were built at the Pittsfield plant which had silver windings! |

| Line 781: |

Line 781: |

| *The <u>High Voltage Laboratory</u> (Building 9) is under construction. | | *The <u>High Voltage Laboratory</u> (Building 9) is under construction. |

|

| |

|

| *<u>Cummings C. Chesney</u> died. | | *[[Cummings C. Chesney|Cummings C. Chesney]] died. |

|

| |

|

| *The old <u>Power House</u> smokestack was torn down. | | *The old <u>Power House</u> smokestack was torn down. |

| Line 1,217: |

Line 1,217: |

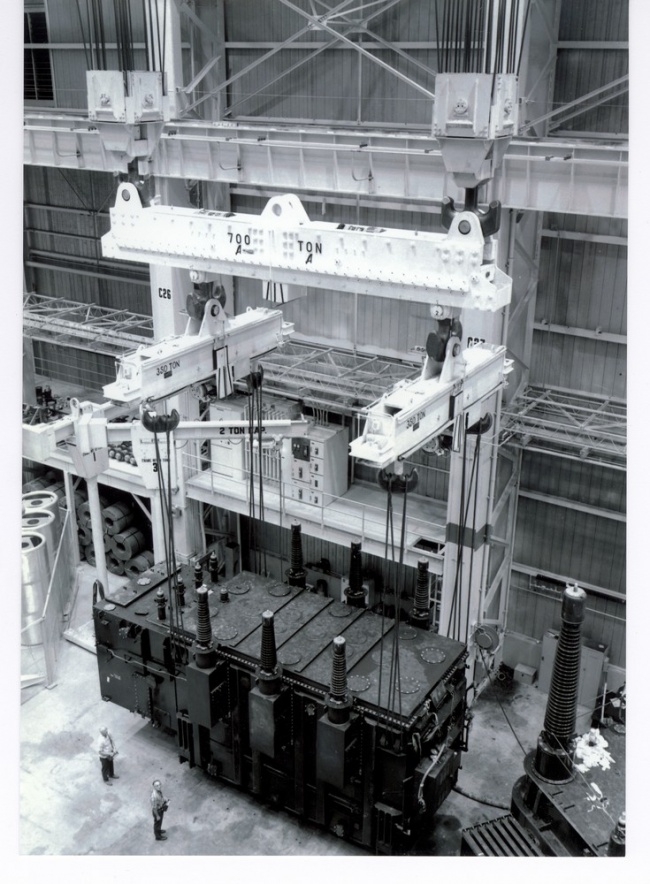

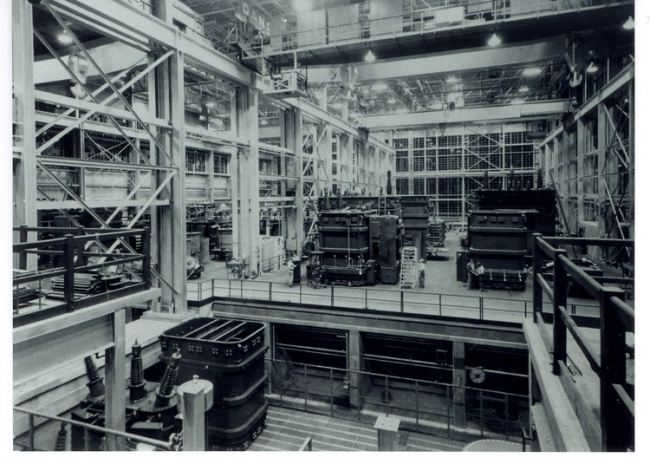

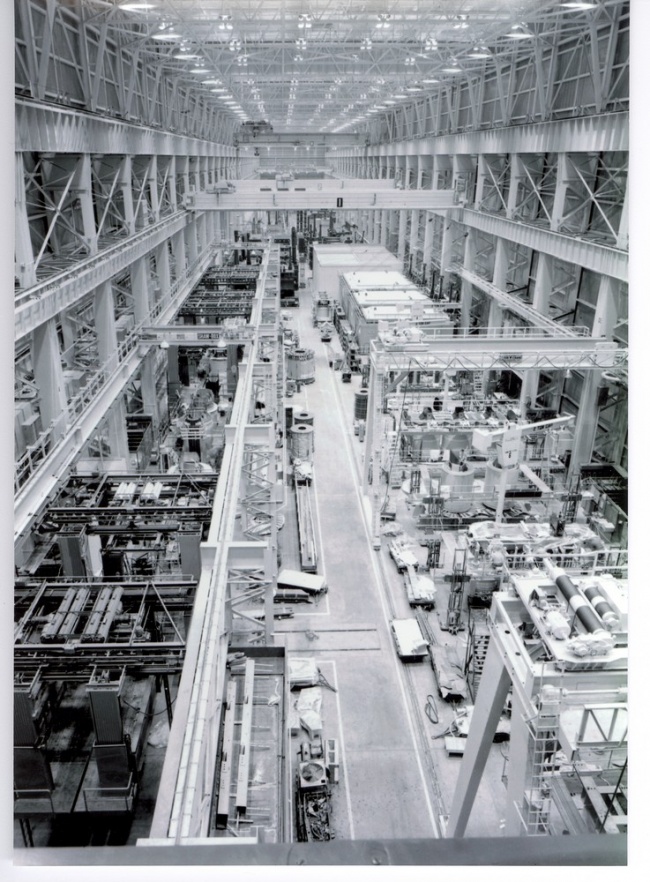

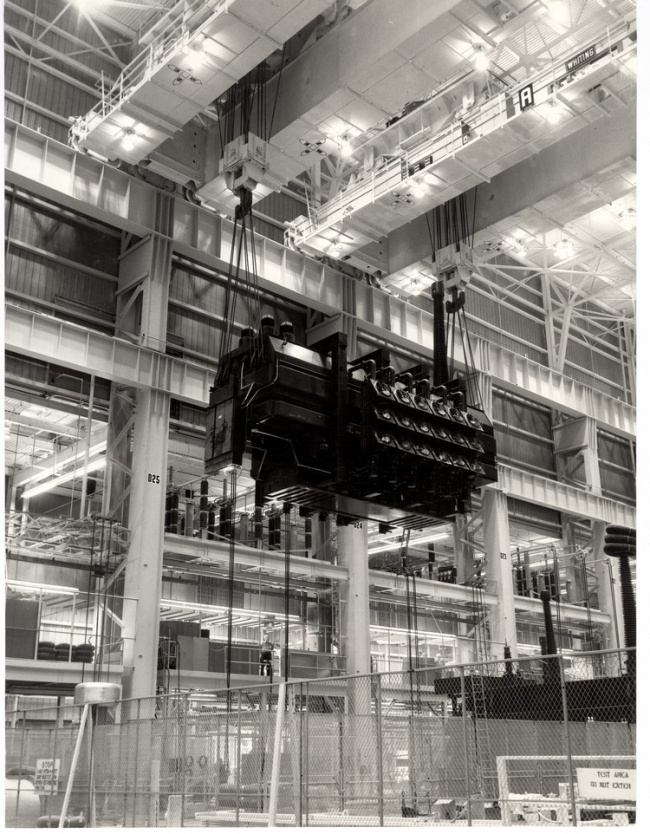

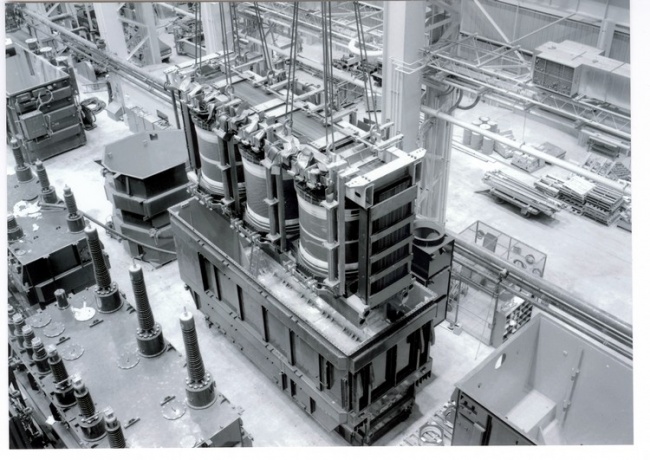

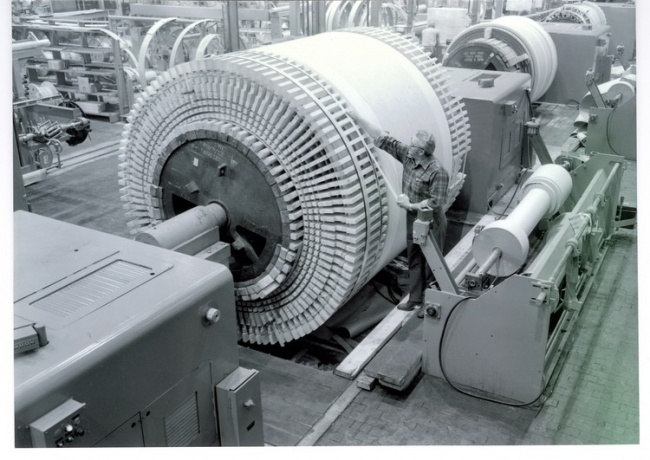

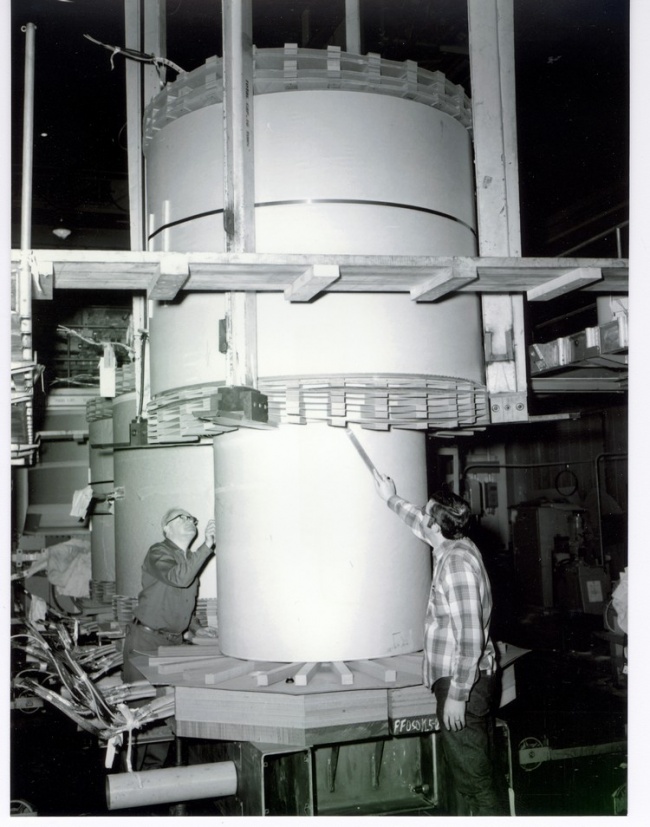

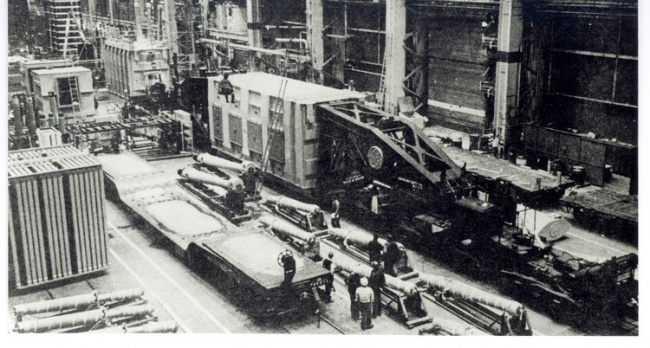

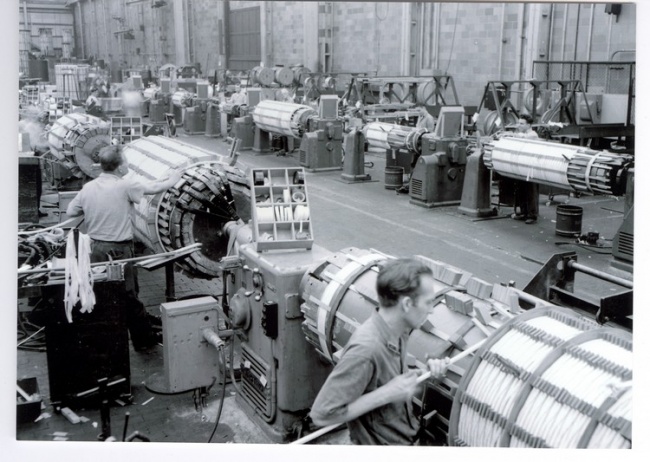

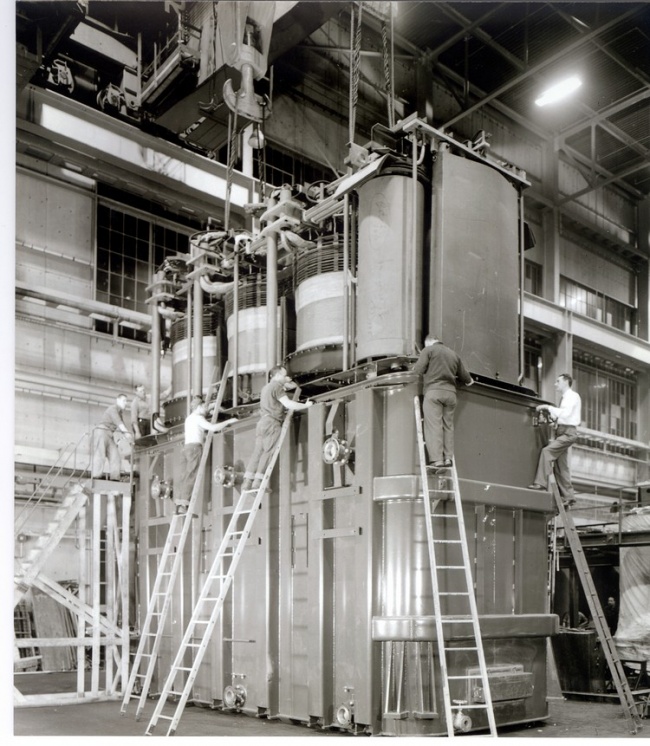

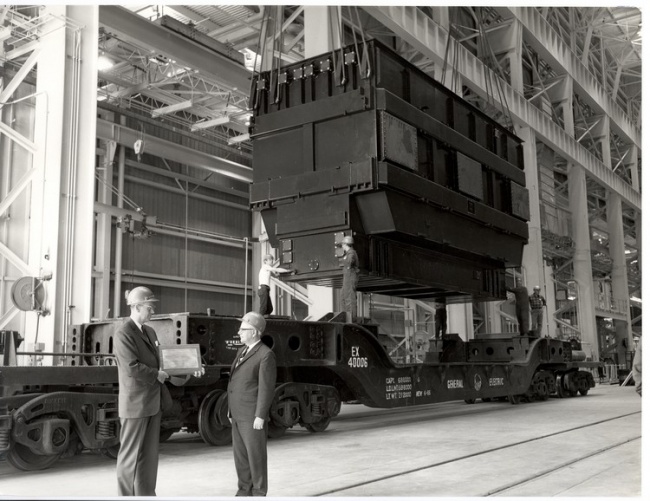

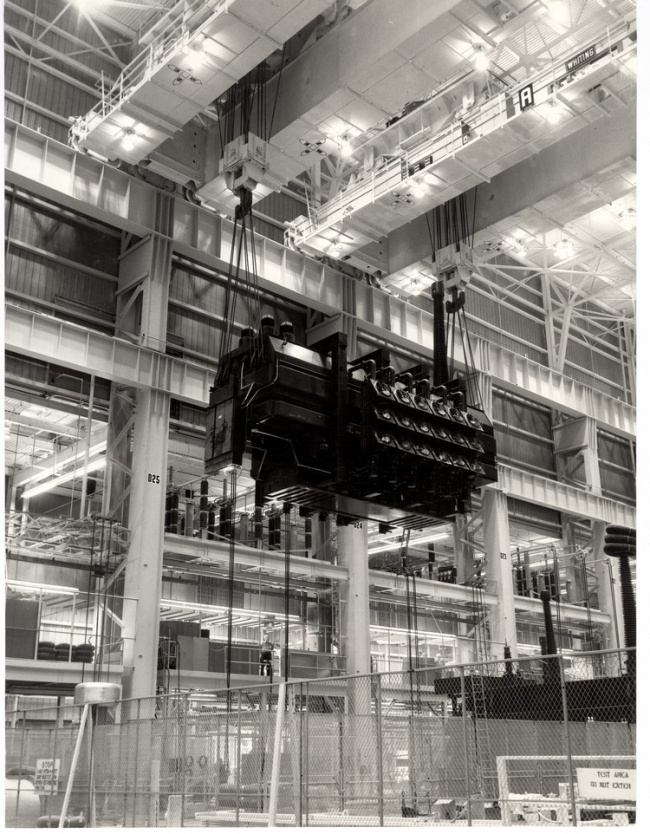

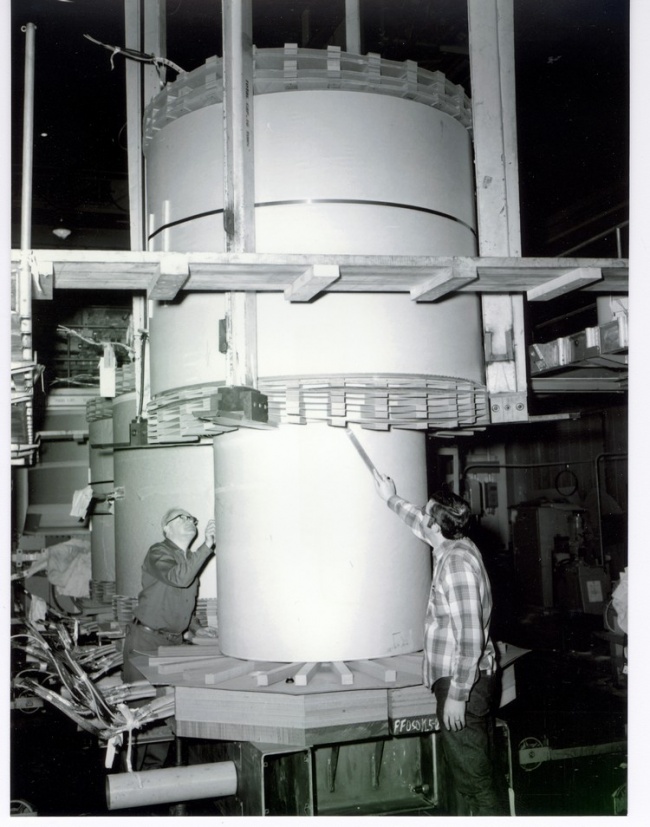

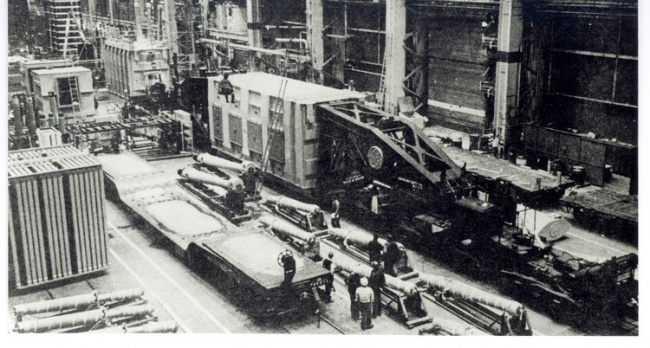

| [[Image:Blalock - page 90 (bot).jpg|thumb|center|650px|A core and coils being tanked in Building 100 courtesy of General Electric Company]] | | [[Image:Blalock - page 90 (bot).jpg|thumb|center|650px|A core and coils being tanked in Building 100 courtesy of General Electric Company]] |

|

| |

|

| <u>Vacuum Treat</u>

| | === Vacuum Treat === |

|

| |

|

| Elaborate precautions were taken to insure that the paper insulation used in the transformer windings was as free of moisture as possible, so as to retain its maximum insulating capability. This was the function of the vacuum treat cycle. | | Elaborate precautions were taken to insure that the paper insulation used in the transformer windings was as free of moisture as possible, so as to retain its maximum insulating capability. This was the function of the vacuum treat cycle. |

| Line 1,425: |

Line 1,425: |

| 1973: | | 1973: |

|

| |

|

| *Les Jump, an engineer who re-located to Pittsfield from the AEI Company of Manchester. in England, warned of the very real possibility of a <u>plant closing</u> here because he had seen | | *Les Jump, an engineer who re-located to Pittsfield from the AEI Company of Manchester. in England, warned of the very real possibility of a <u>plant closing</u> here because he had seen it happen there! |

| | |

| it happen there! | |

|

| |

|

| *A <u>Family Day</u> was held in the plant in April. | | *A <u>Family Day</u> was held in the plant in April. |

| Line 1,437: |

Line 1,435: |

| *Competitor <u>Central Moloney</u> of St. Louis, Missouri went out of the power transformer business. | | *Competitor <u>Central Moloney</u> of St. Louis, Missouri went out of the power transformer business. |

|

| |

|

| *<u>ASEA</u> of Sweden won a large order from the Commonwealth Edison Company, of Chicago, beating out General Electric, Westinghouse, | | *<u>ASEA</u> of Sweden won a large order from the Commonwealth Edison Company, of Chicago, beating out General Electric, Westinghouse, and the McGraw-Edison Company. This was for seven single-phase generator step-up transformers. |

| | |

| and the McGraw-Edison Company. This was for seven single-phase generator step-up transformers. | |

|

| |

|

| *The New England Power Company's <u>Bear Swamp</u> pumped storage hydroelectric, generating facility on the Deerfield River (in the towns of Florida and Rowe, Mass.) was soon to go "on-line". This plant used two generator step-up transformers from Pittsfield with their two 300-Megawatt generators. | | *The New England Power Company's <u>Bear Swamp</u> pumped storage hydroelectric, generating facility on the Deerfield River (in the towns of Florida and Rowe, Mass.) was soon to go "on-line". This plant used two generator step-up transformers from Pittsfield with their two 300-Megawatt generators. |

| Line 1,465: |

Line 1,461: |

| 1975: | | 1975: |

|

| |

|

| *Three new <u>winding lathes</u>(vertical type) were installed in Building 1, plus two of | | *Three new <u>winding lathes</u>(vertical type) were installed in Building 1, plus two of the more conventional horizontal type. |

| | |

| the more conventional horizontal type. | |

|

| |

|

| *The G.E. Transformer Division's computers were all centralized in <u>Building 34</u> on East Street. | | *The G.E. Transformer Division's computers were all centralized in <u>Building 34</u> on East Street. |

| Line 1,539: |

Line 1,533: |

| 1981: | | 1981: |

|

| |

|

| *<u>Building 73,</u> a regulator life-test facility, | | *<u>Building 73,</u> a regulator life-test facility, was constructed off of New York Avenue. |

| | |

| was constructed off of New York Avenue. | |

|

| |

|

| *The <u>Silver Lake Barge</u> was dismantled. This had been a facility on Silver Lake, operated by G.E. Ordnance, for the purpose of torpedo sonic testing. | | *The <u>Silver Lake Barge</u> was dismantled. This had been a facility on Silver Lake, operated by G.E. Ordnance, for the purpose of torpedo sonic testing. |

| Line 1,603: |

Line 1,595: |

| 1986: | | 1986: |

|

| |

|

| *A <u>rumor</u> circulated that foreign competitor ASEA planned to take over the Pittsfield | | *A <u>rumor</u> circulated that foreign competitor ASEA planned to take over the Pittsfield operation. This proved to be untrue. |

| | |

| operation. This proved to be untrue. | |

|

| |

|

| *The announcement of the end of the transformer business in Pittsfield was made in the Berkshire Eagle on November 22. <u>One thousand jobs would be lost.</u> | | *The announcement of the end of the transformer business in Pittsfield was made in the Berkshire Eagle on November 22. <u>One thousand jobs would be lost.</u> |

| Line 1,647: |

Line 1,637: |

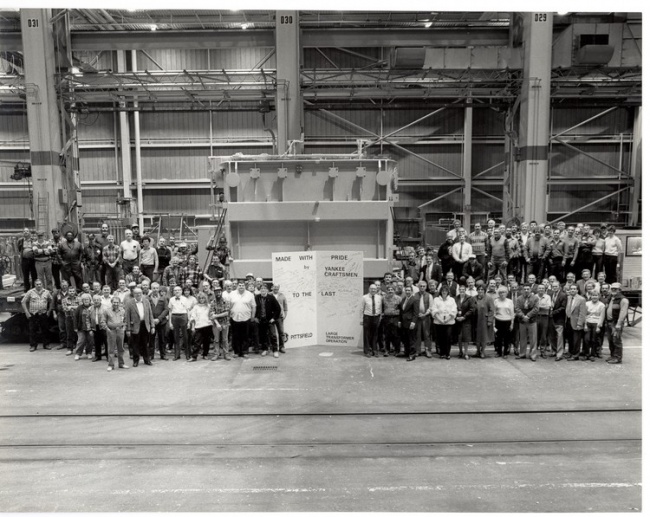

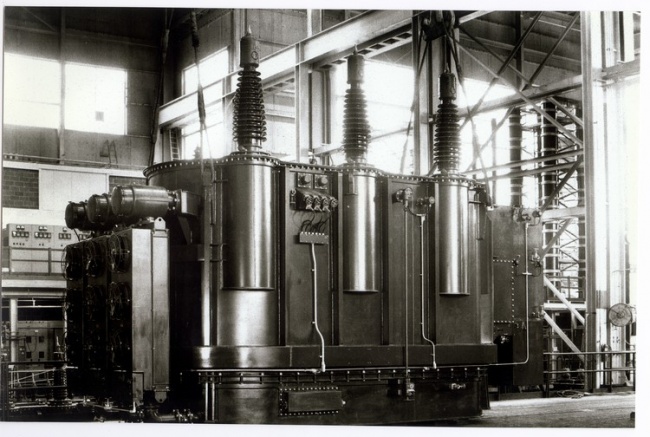

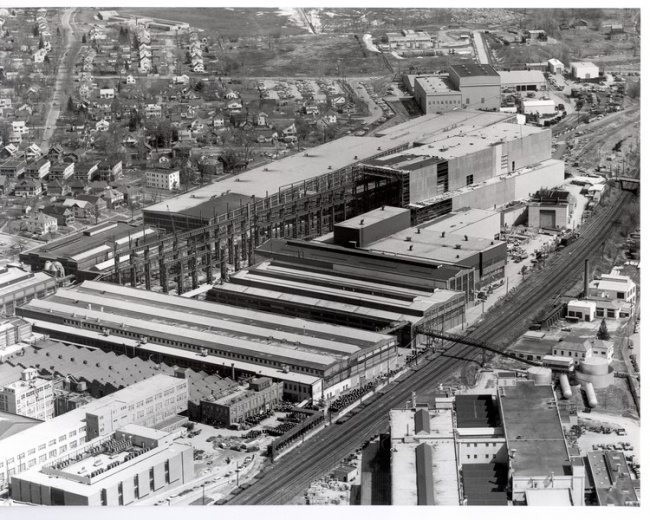

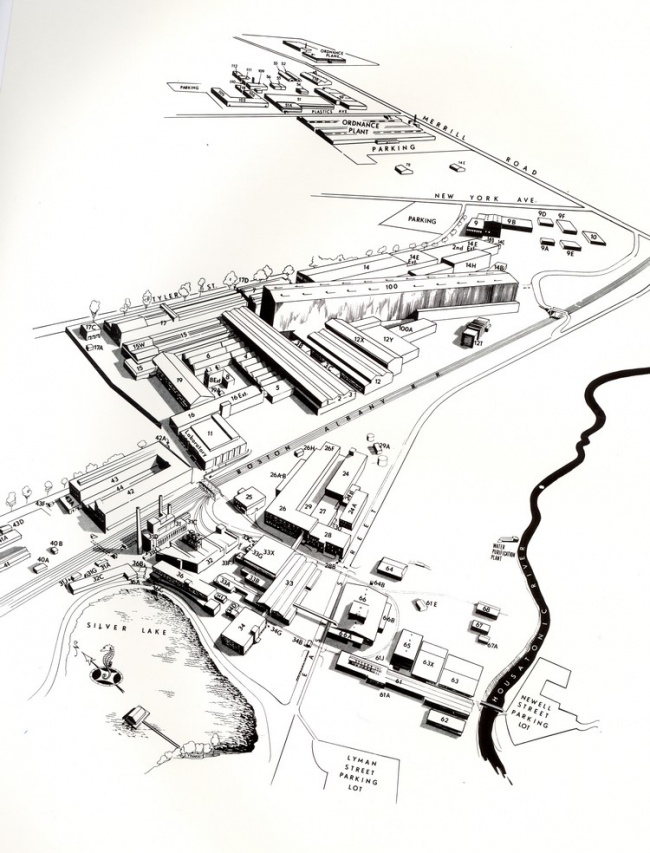

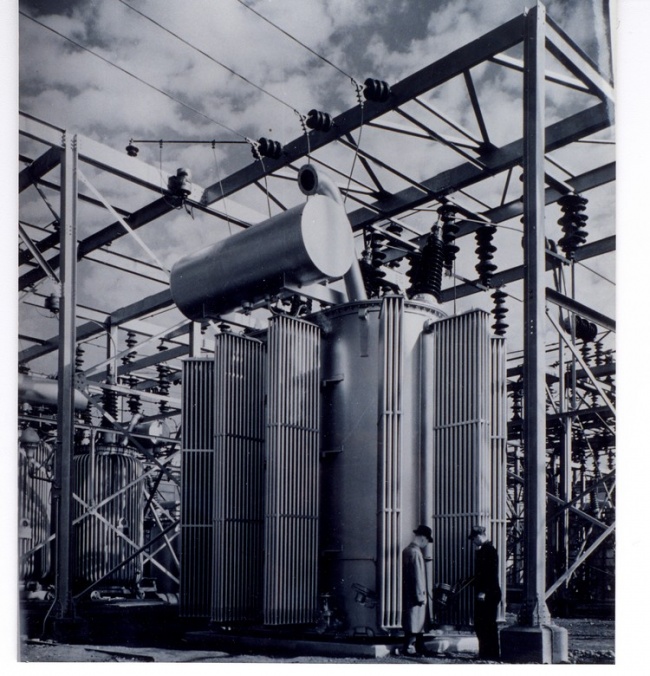

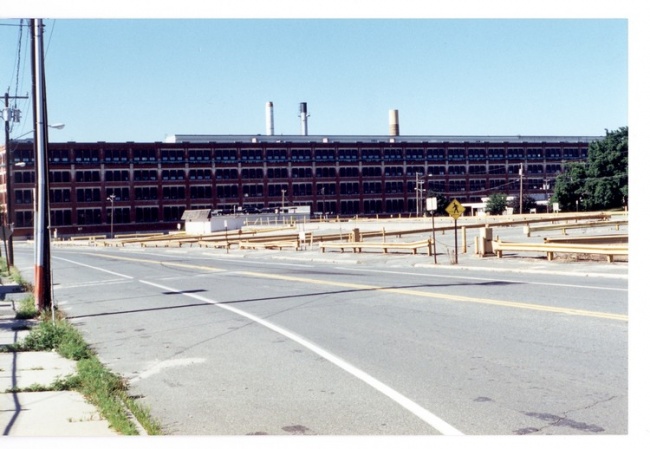

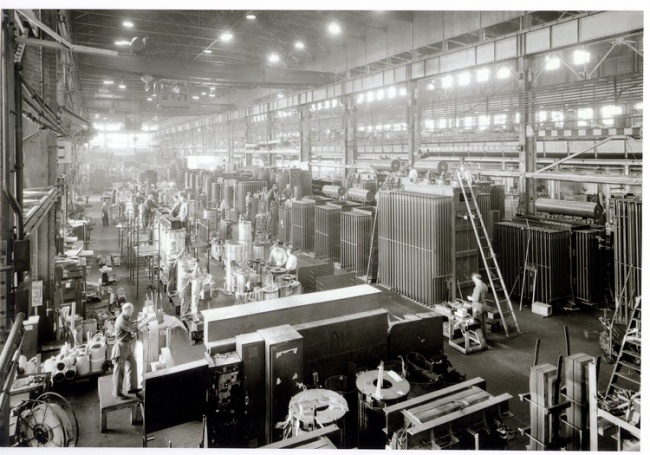

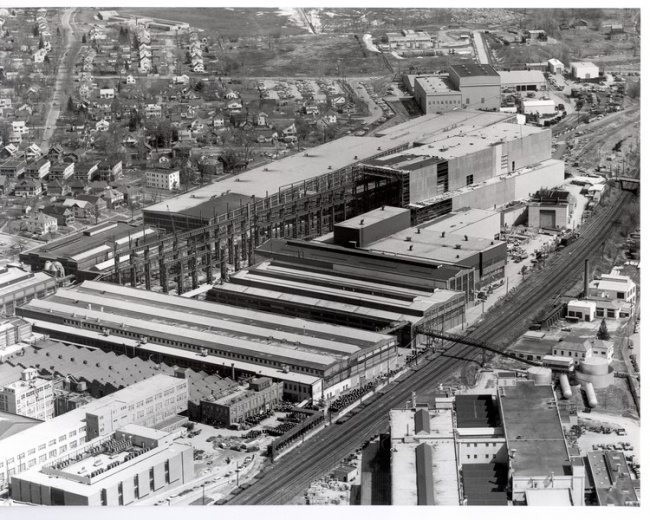

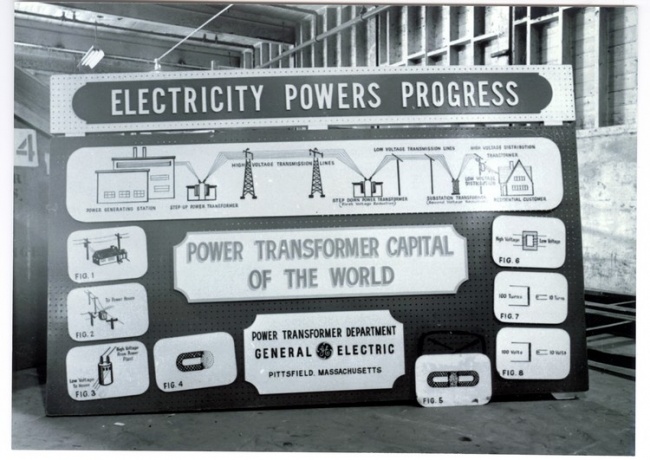

| [[Image:Blalock - page 126.jpg|thumb|center|650px|"Power Transformer Capital of the World" (Pittsfield, Mass.); courtesy of General Electric Company (1975)]] | | [[Image:Blalock - page 126.jpg|thumb|center|650px|"Power Transformer Capital of the World" (Pittsfield, Mass.); courtesy of General Electric Company (1975)]] |

|

| |

|

| == Chapter 9: The High Voltage Laboratory ==

| | To read more, continue to [[Archives:Transformers at Pittsfield, part 2|Transformers at Pittsfield, part 2]]. |

| | |

| "The most powerful lightning bolts ever created by man ripped through the air this week as the new High Voltage Engineering Laboratory of the General Electric Company was opened officially."

| |

| | |

| "Julius H. Hagenguth, engineer in charge of the laboratory, supervised the firing of artificial lightning more than fifty feet through the air in the huge demonstration hall of the laboratory, described as 'the world's largest man-made lightning center'."

| |

| | |

| ('Transformer and Allied Products News', June 24, 1949)

| |

| | |

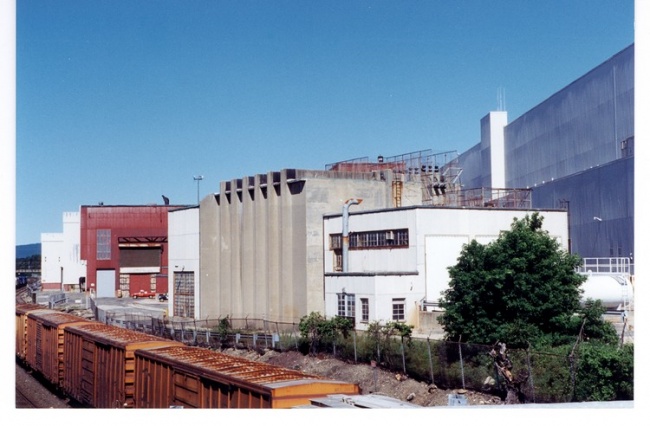

| The "demonstration hall" referred to above was the "High Bay" area of the new Building 9, located on Tyler Street Extension, in the Pittsfield G.E. plant. This building still stands today, but is essentially abandoned as a result of the closing of the Pittsfield transformer operation in 1987. The building is distinguished by an aluminum and glass block main entrance facade in the Art Deco style which was still in vogue at the time of its construction in 1948-49.

| |

| | |

| The "lightning bolts" were discharges from devices known as impulse generators. These giant stacks of capacitors allowed for the production of extremely high surge voltages which could be made to _duplicate the surges created in electric power systems by natural lightning. Thus, the effects of these surges on electrical equipment could be studied in a laboratory environment.

| |

| | |

| During its heyday, the G.E. High Volt Lab was known the world over as a center of lightning research. Its abandonment as a consequence of the closing of the G.E. transformer operation in Pittsfield represents a significant loss to the prestige of the community.

| |

| | |

| Following the plant closing, the nearly fifty year old, but still perfectly functional, High Bay impulse generators were destroyed because the capacitors which were the basis of their operation contained Pyranol. This insulating fluid had been outlawed in 1977 because it contained suspected carcinogens ("PCB's").

| |

| | |

| Julius Hagenguth had died in 1969 at the age of 67, just three years after his formal retirement from the High Voltage Laboratory.

| |

| | |

| The history of the High Voltage Laboratory goes back much farther than the opening of Building 9 in 1949. It began when the need for the investigation of the exact nature of lightning-induced surges arose with the development of high voltage transmission of electric power over long distances. Long transmission lines, as well as the electrical equipment connected to them, are susceptible to high voltage surges from lightning strikes either to the line itself, or nearby.

| |

| | |

| The equipment connected to the ends of high voltage transmission lines is susceptible to extensive damage as a result of such surges. Since this equipment is most apt to be in the form of a transformer, it was logical for the investigation of lightning surges to

| |

| | |

| be a part of the development of the transformer industry itself.

| |

| | |

| As early as 1894, William Stanley and his associates experimented with a short transmission line operating

| |

| | |

| at 15,000 volts (15-kv). This was in the southeastern section of the City of Pittsfield, in the vicinity of what is now the intersection of Wendell Avenue and Colt Road. By 1900, commercial transmission lines operating at 40 to 60-kv were in use, and, by 1910, the upper limit of transmission voltages had reached 100-kv.

| |

| | |

| More basic to the development of such high voltage transmission lines than the effects of lightning surges was the design of insulation capable of standing up to these high normal operating voltages. Transformers were designed just for the purpose of developing such

| |

| | |

| high voltages in a laboratory environment so that insulating structures could be tested before being put into commercial use.

| |

| | |

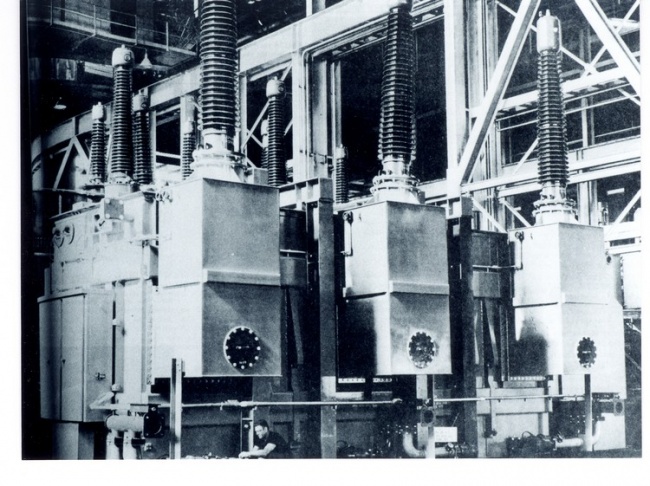

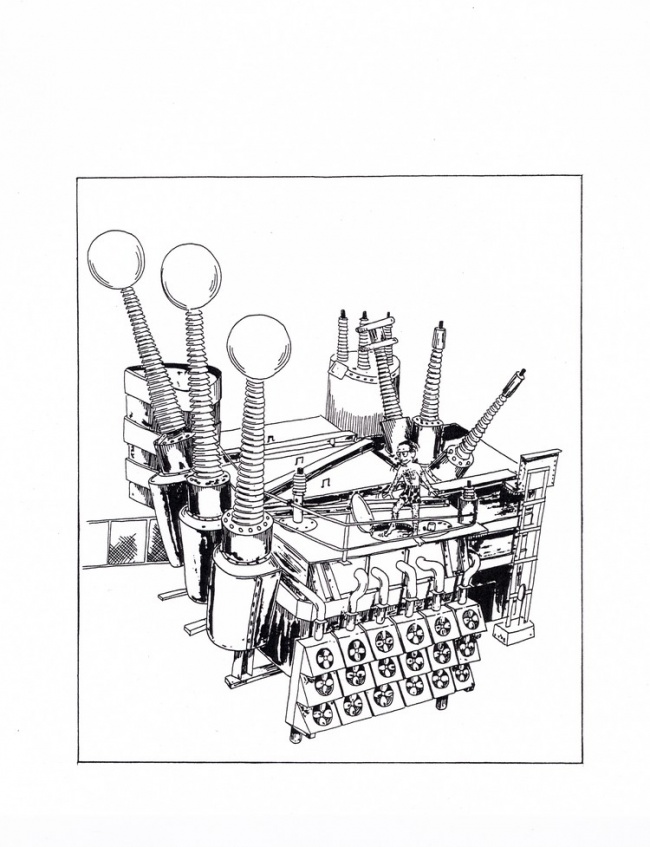

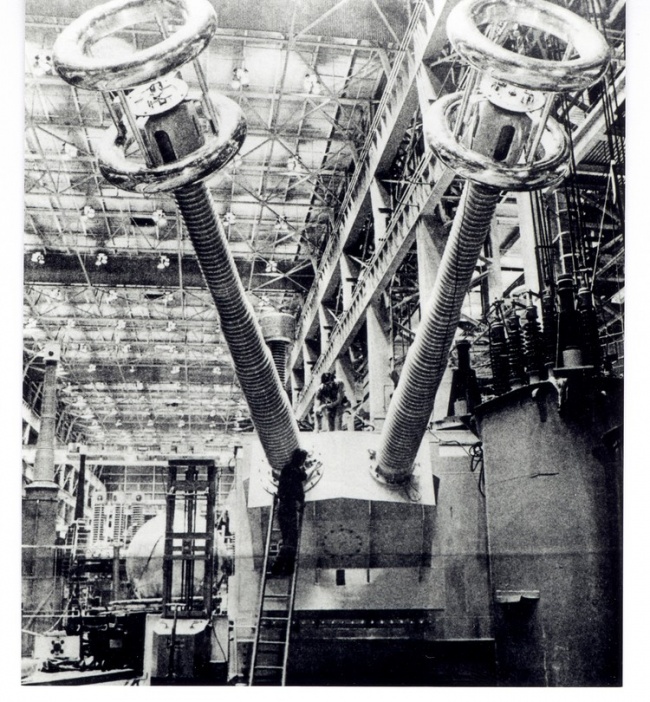

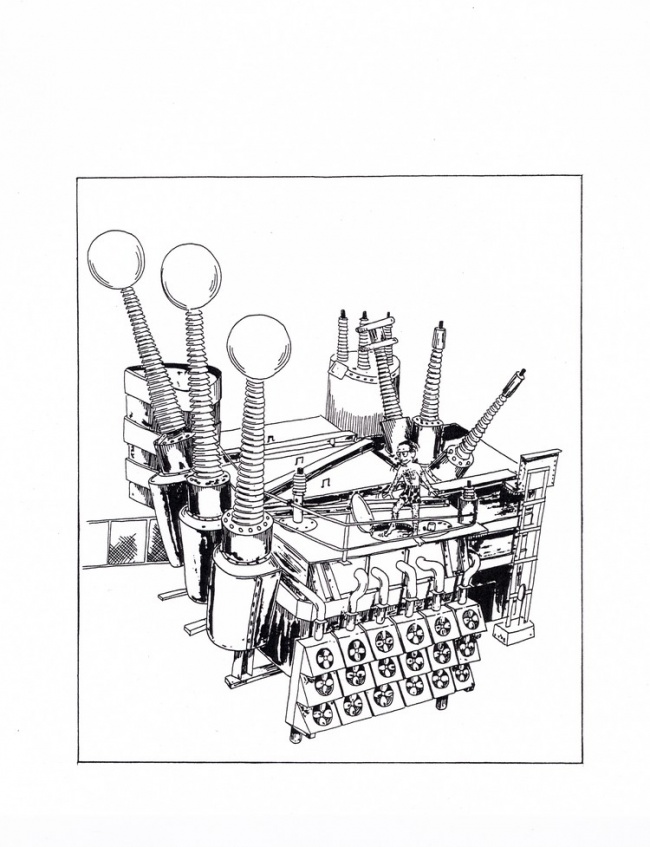

| Ultimately, special testing transformers known as "cascade transformers" were developed in order to obtain extremely high power frequency (usually 60-Hertz) voltages. This technique involved the use of two or more transformers connected in "cascade" so as to add their individual voltages together.

| |

| | |

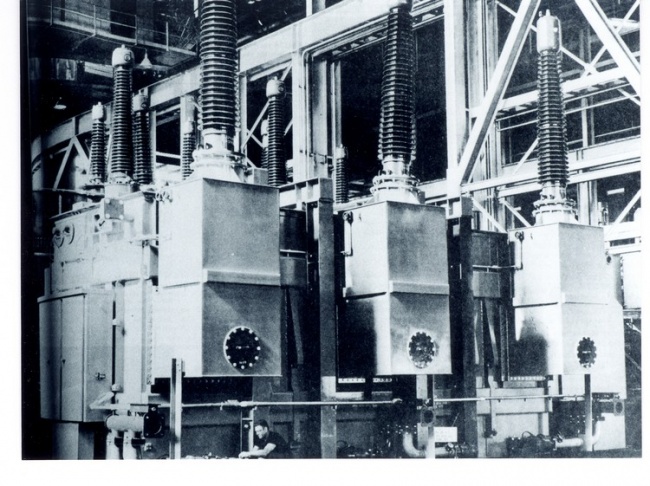

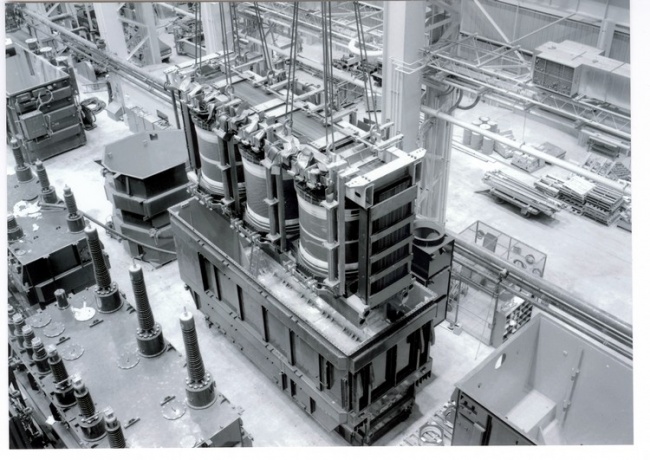

| [[Image:Blalock - page 129.jpg|thumb|center|650px|Three cascade transformers producing 1.05-MV NOTE: The steel tanks of Transformers No. 2 and No. 3 must be physically and electrically insulated from ground.]]

| |

| | |

| [[Image:Blalock - page 130 (top).jpg|thumb|center|650px|Main Entrance of Building 9 in 1996, photo by author]]

| |

| | |

| [[Image:Blalock - page 130 (bot).jpg|thumb|center|650px|Three cascade transformers in Building 9 courtesy of General Electric Company]]

| |

| | |

| Defective high voltage insulation can lead to actual breakdowns called "flashovers" or "arcovers" which cause a short circuit on the transmission line or in the piece of equipment where the breakdown occurs. However, even if this extreme a problem does not occur, less than adequate insulation strength can give rise to a phenomenon known as "corona". This is a partial breakdown of the air in the vicinity of a high voltage conductor. Corona caused by the very high voltage static charges which precede a lightning stroke was called "St. Elmo's Fire" by sailors on old sailing ships. The corona appeared at the tops of the masts and produced a bluish glow in the nighttime. Corona on high voltage power lines can create the same visual effect, and it also causes severe static on AM radios in the vicinity.

| |

| | |

| If corona discharges are left uncorrected, the insulation over which they occur will be damaged as time progresses. Also, even if insulation damage is not a prime consideration (such as with corona on a bare conductor), the energy expended in the corona discharge represents a loss on a power system. This degrades the over-all efficiency of the system. In any case, it is evident that corona should be avoided by proper design of the insulation involved.

| |

| | |

| In 1909, the first serious study of the corona phenomenon was undertaken by Giuseppe Faccioli and W.S. Moody of the Pittsfield transformer operation. In 1910, F.W. Peek developed the first mathematical basis for determining the probability of corona occurring in a high voltage system. To this end, Peek used 250-kv transformers designed by A.B. Hendricks, Jr. to conduct experimental tests of corona phenomena. By 1913, a building designated as "3B" in the Pittsfield plant was called "High Tension and High Frequency Test" and was used for the purpose of conducting testing such as this. Building 3B was adjacent to transformer assembly Building 3.

| |

| | |

| At the same time, the lightning arrester development group in Pittsfield had begun to experiment with lightning-type surges with the aid of a crude form of impulse generator. It was called a "lightning generator" and was capable of producing discharges of up to 200-kv in magnitude.

| |

| | |

| By 1914, these types of investigations had become sophisticated enough that some means of displaying the waveform of the surge which was being produced became a priority. At this time, Alexander Dufour was experimenting with the placement of photographic film inside an evacuated chamber, and the use of a beam of electrons to "write" an image onto the film. Eventually, the evacuated chamber and electron beam became known as a "cathode ray tube" and, as such, formed the basis for the electronic instrument known as an oscilloscope, which is still very much in use today. Also, for the photographic recording of surges, the film eventually was moved to a camera located outside of the cathode ray tube. This greatly expedited the operating procedure; with the old arrangement, a new vacuum had to be pulled in the chamber every time the film was changed!

| |

| | |

| When Building 9 was constructed in 1949, the lightning arrester development group was given space on the third floor. They used a Dufour-type "cold-cathode" oscillograph in their work for many years. Tom Carpenter, an engineer who joined this group in 1937 and retired in 1976, was an expert in the operation of this device.

| |

| | |

| Normally, a constant high voltage (D.C.) would be used to energize the electron beam mechanism of such a device. In this case, however, in order to reduce the degradation of the cathode element, a short duration pulse was supplied for this purpose by a 70-kv impulse generator. The electron beam thus produced was allowed to write a trace on either a fluorescent screen for immediate viewing, or onto a photographic film. An arrangement within the evacuated chamber, operated from the outside, allowed one of six films (or the screen) to be rotated into the path of the beam. Thus, six records could be made without breaking the vacuum. It took about one hour to change films and re-establish the vacuum!

| |

| | |

| The advantages of this device over the more convenient hot cathode type of oscilloscope included the fact that it was capable of producing photographic records of extremely short duration surges which had very high quality. It would be many years before sealed cathode ray tubes could produce comparable images.

| |

| | |

| As transmission voltages rose higher and higher, the need for greater magnitudes of voltage for surge testing followed .accordingly. Thus, in 1916, the arrester group's lightning generator was uprated from 200-kv to 750-kv.

| |

| | |

| The year 1914 marked the establishment of the High Voltage Engineering Laboratory as an entity within the Pittsfield plant. The facility used for this new operation was Building 12A, a section located at the north end of the new Building 12 transformer assembly and testing building then under construction.

| |

| | |

| In 1921, Faccioli and Peek produced the first one million volt 60-Hertz discharge in this new facility. In addition, a one million volt experimental transmission line was erected from Building 12A running through the plant to the east. The steel lattice towers used to support this line remained in place for many years thereafter.

| |

| | |

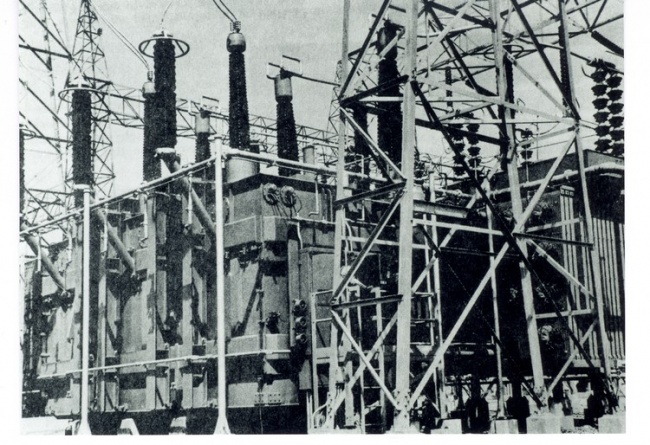

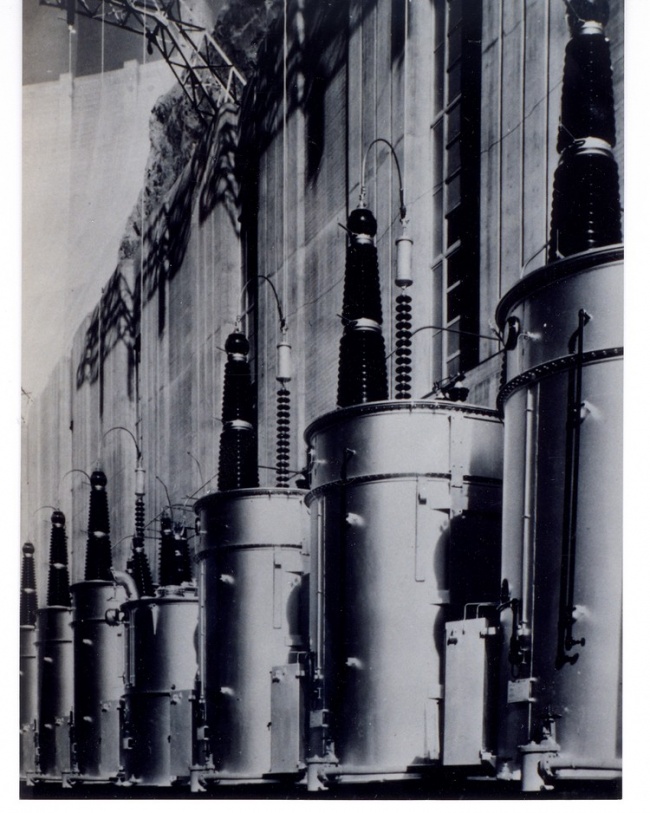

| At this same time, the first 220-kv transmission line for commercial use was put into operation by the Big Creek Power Company in California (later to become a part of the Southern California Edison Company). The transformers used to energize this line were designed in Pittsfield by F.F. Brand and J.J. Frank of the transformer engineering operation.

| |

| | |

| [[Image:Blalock - page 133.jpg|thumb|center|650px|The cold-cathode oscillograph in use courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 134 (top).jpg|thumb|center|650px|The High Voltage Lab in Building 12A; G.E. Current News, July, 1926]]

| |

| | |

| [[Image:Blalock - page 134 (bot).jpg|thumb|center|650px|One million volt arc in Building 12A; G.E. Current News, November, 1921]]

| |

| | |

| === High Current Testing ===

| |

| | |

| In 1920, the summer camp of the legendary General Electric scientist and mathematical genius, Charles Proteus Steinmetz, was struck by lightning. His camp was on the Mohawk River near Schenectady, New York, his base of operations. Accordingly, Steinmetz became very interested in the explosive and incendiary effects of natural lightning.

| |

| | |

| As a result, Steinmetz designed and built a 120-kv lightning generator. The notable feature of this machine, however, was that it could produce discharges of up to 10,000 amperes so as to simulate the destructive effects of natural lightning. This generator used the newly-developed "Kenotron" high vacuum rectifier tube to produce direct current of sufficient voltage to charge the capacitors which formed the circuitry of the generator.

| |

| | |

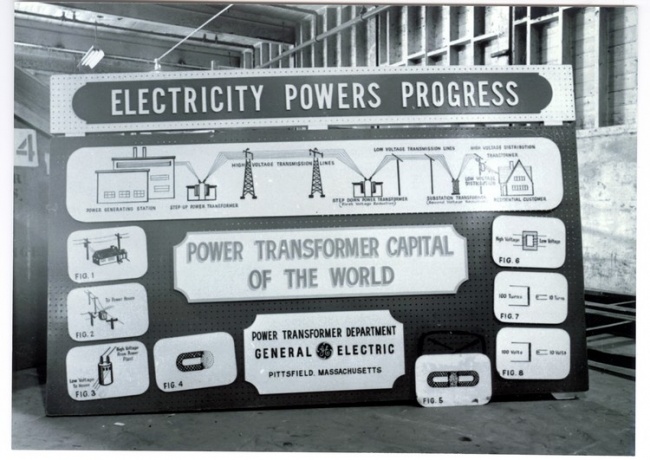

| Steinmetz died shortly thereafter, in 1923. However, his work with high surge currents was continued in Pittsfield. In 1934, a high current generator was constructed which was capable of producing discharges of 265,000 amperes at a voltage of 50-kv. It used a group of capacitors totaling about fifty microfarads arranged in a hollow square configuration. The test piece (the object which was to receive this blast of current) was placed in the center of the arrangement.

| |

| | |

| According to one observer of the time:

| |

| | |

| "One of the first things to be discovered was the extraordinarily loud report resulting from a high current discharge in the air. From the spark there also emanated a pressure wave which would rock bystanders back upon their heels, and could be felt effectively on the chest thirty feet away. These characteristics, in addition to the aforementioned flying debris - bits of wood, metal, and concrete - made it necessary to house the test piece inside a box made of two-inch wooden planks. This procedure increased our comfort and safety considerably."

| |

| | |

| [[Image:Blalock - page 136 (top).jpg|thumb|center|650px|The high current generator; General Electric Review, March, 1935]]

| |

| | |

| [[Image:Blalock - page 136 (bot).jpg|thumb|center|650px|Above generator re-built in Building 9 courtesy of General Electric Company]]

| |

| | |

| === Further Developments ===

| |

| | |

| In 1922, A.B. Hendricks, Jr. first demonstrated a one million volt three-phase arc. He used three testing transformers which stepped 2500 volts up to 578-kv to ground. This gave 1000-kv phase-to-phase.

| |

| | |

| In later years, the three-phase arc became a feature of the High Voltage Laboratory shows during transformer plant Open House events for families and friends of the transformer employees. In the name of showmanship, a technique was developed whereby the three electrodes for the arc were treated with different chemicals. This caused the three branches of the arc to assume different colors (strontium nitrate made red, sodium chloride made yellow, and thallium nitrate made green).

| |

| | |

| In 1923, a new two million volt lightning generator was built for use in Building 12A. It was designed by W.L. Lloyd, Jr. At this time, the High Voltage Engineering Lab operation was under the leadership of Royal Meeker. In addition, there were laboratory operations in Building 7 ("Instrument and General Testing Lab"), and in Building 8 ("Electrical Testing and Development Lab").

| |

| | |

| In 1924, two Dufour oscillographs were purchased-, by the High Voltage Engineering Lab, Also, a one million volt cascade transformer testing set was built for use at the Philadelphia General Electric plant. It was used for the testing of switchgear insulation.

| |

| | |

| In 1927, a portable one million volt impulse generator was built for field-testing transmission line insulator strings. In 1929, this generator was used for tests on the 115-kv transmission line running from Turner's Falls, Mass, to the Silver Lake Substation adjacent to the Pittsfield plant. In 1931, a new 1.5 million volt portable impulse generator was built to continue this work at higher voltage levels.

| |

| | |

| Meanwhile, larger and larger impulse generators were being built for use in the High Voltage Engineering Lab itself. In 1928, Peek designed a 3.6 million volt generator. This was followed by a five million volt generator in 1929, and then a ten million volt version in 1932.

| |

| | |

| Frank W. Peek was named Chief Engineer of the Pittsfield Works in 1931. Very unfortunately, however, he was killed in an automobile accident in 1931. At this time, Karl B. McEachron took over in his place. In 1930, McEachron had developed a material called "Thyrite" which was then patented by G.E. This material was a silicon carbide composition which exhibited the unique property of having a decreasing electrical resistance as the voltage applied to it was increased. Thus, it found great usage in lightning arresters which could, with the aid of Thyrite, limit surge overvoltages on power systems in which they were connected.

| |

| | |

| The High Voltage Engineering Laboratory was also very much involved in investigations of natural lightning during this time. In 1928, the first oscillographic record ("oscillogram") of natural lightning had been obtained. In 1934, a lightning observatory was built on the roof of Building 42 in the Pittsfield plant,

| |

| | |

| Also, in 1934, lightning tests were conducted on underground power cables at what was known as the "old Allen Farm" in Pittsfield. This was in the vicinity of the present Allengate Avenue. Such work was aided by the use of an improved form of impulse generator (the "Marx" circuit) which had been invented in 1925.

| |

| | |

| [[Image:Blalock - page 139 (top).jpg|thumb|center|650px|The one million volt three-phase arc; G.E. Current News, November, 1922]]

| |

| | |

| [[Image:Blalock - page 139 (bot).jpg|thumb|center|650px|The high current generator; General Electric Review, March, 1935]]

| |

| | |

| [[Image:Blalock - page 140 (top).jpg|thumb|center|650px|The two million volt impulse generator. G.E. Current News, July, 1923]]

| |

| | |

| [[Image:Blalock - page 140 (bot).jpg|thumb|center|650px|A ten million volt discharge in Building 12A G.E. 'Monogram', June, 1938]]

| |

| | |

| [[Image:Blalock - page 141 (top).jpg|thumb|center|650px|The lightning observatory on Building 42; Pittsfield G.E. News, August 2, 1935]]

| |

| | |

| [[Image:Blalock - page 141 (bot).jpg|thumb|center|650px|Three cascade transformers in Building 12A G.E. Current News, November, 1925]]

| |

| | |

| [[Image:Blalock - page 142.jpg|thumb|center|650px|"Experimental High Potential Test" (Building 12A, 1915); courtesy of Judy Rupinski, Pittsfield, MA]]

| |

| | |

| === Building 9 ===

| |

| | |

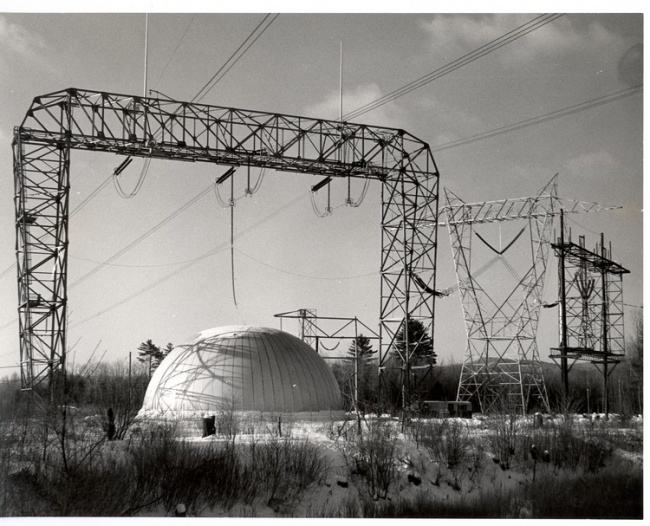

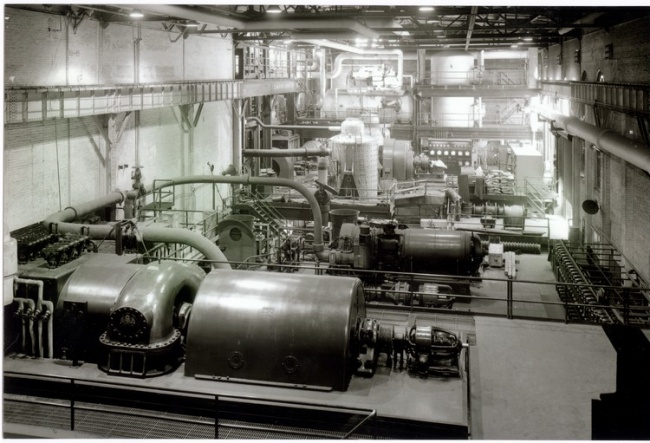

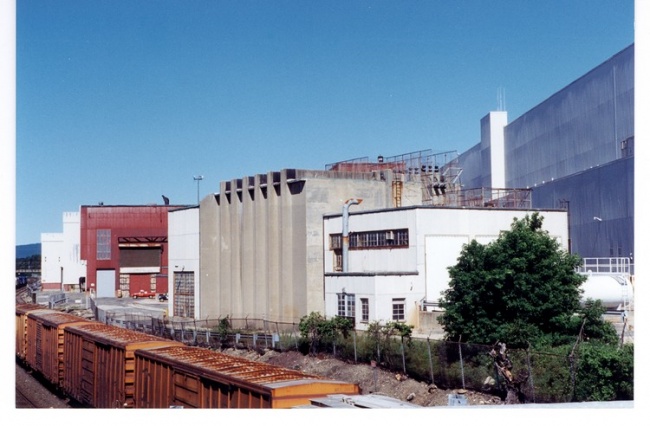

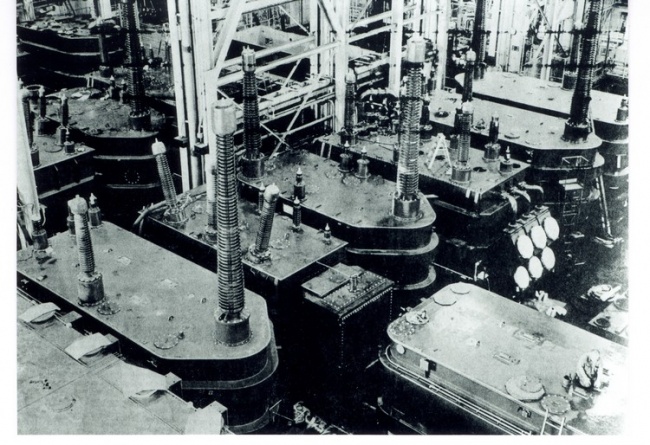

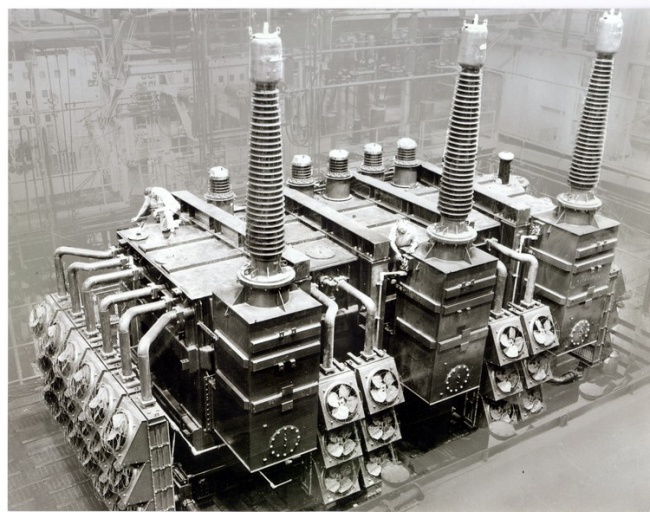

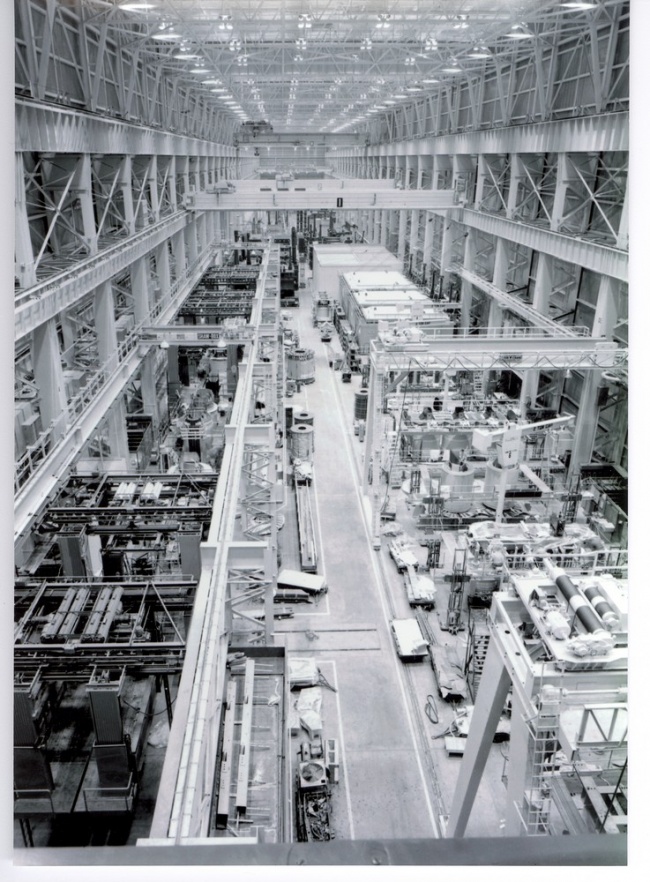

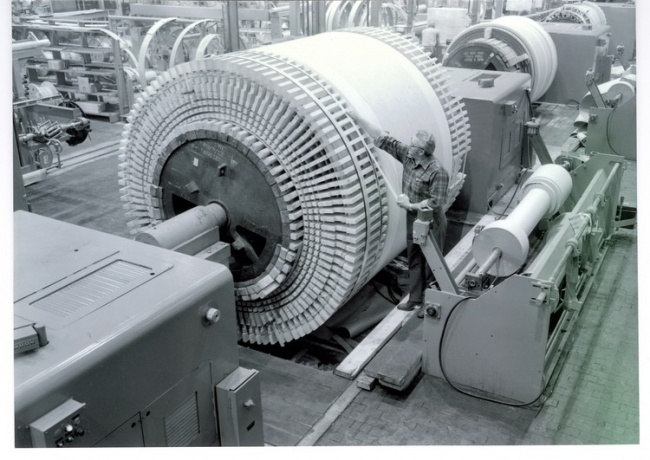

| A new High Voltage Laboratory facility, Building 9 on Tyler Street Extension, officially opened in June of 1949. The building still stands and consists of two main structural parts. These were referred to as the "High Bay" and the "Low Bay" when the Lab was in operation. The High Bay contained two major test areas, each equipped with a 5.1 million volt impulse generator. The Low Bay contained smaller test areas, offices, and an area devoted to lightning arrester development on the third floor.

| |

| | |

| The High Bay section of the building is 165 feet long by 95 feet wide. The height to the roof trusses is 75 feet. A 25-ton bridge crane, which is 65 feet above the floor, was the longest span overhead crane of its capacity in the world when installed. One of the two High Bay impulse generators was mounted on an electrically-driven wagon, and could be moved outdoors for testing which required even greater clearances than were available inside. Tracks carried the wagon and generator through a fifty foot high rolling door which was the largest such overhead door in the world when installed. Power to operate cascade transformers located in the various test areas in the building was obtained from motor-generator sets in a room in the Low Bay section of the building. There was a 1000-Kva test alternator driven by a synchronous motor. This motor operated from the 13,800-volt, three-phase, 60-Hertz plant power system and the alternator it drove could supply only 60-Hertz power to the test areas. A second such synchronous motor drove a 500-volt D.C. generator which, in turn, supplied a D.C. motor driving two 500-Kva test alternators. This variable-speed link allowed these two alternators to supply frequencies other than 60-Hertz if necessary (such as 25-Hertz or 50-Hertz). The Low Bay test areas occupied the three-storey high eastern end of this section of the building. It was served by a 10-ton capacity overhead crane. The first and second floors of the western section housed offices, shops, and darkrooms. The third floor was occupied by offices and test areas for lightning arrester development work. The two-storey high motor-generator room was also in this section, as was the two-storey climate-controlled test area ("Area 5").

| |

| | |

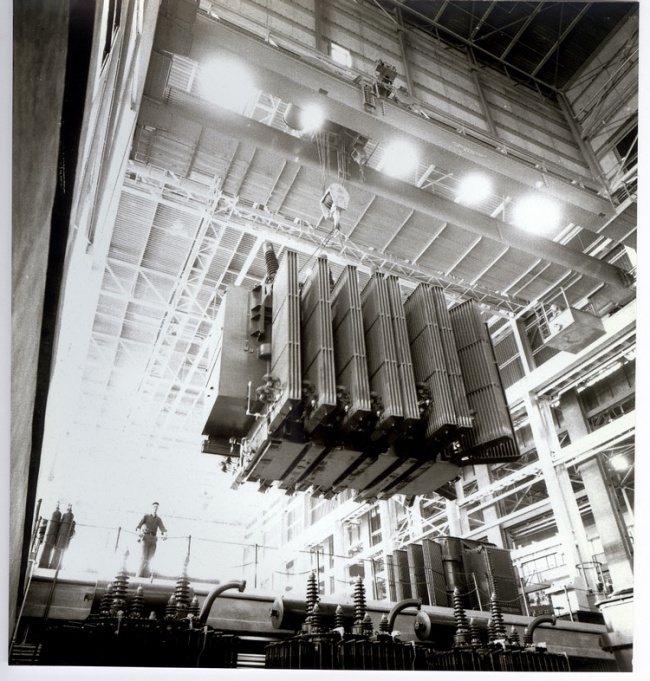

| [[Image:Blalock - page 144.jpg|thumb|center|650px|Building 9 Low Bay (first floor), (1949)]]

| |

| | |

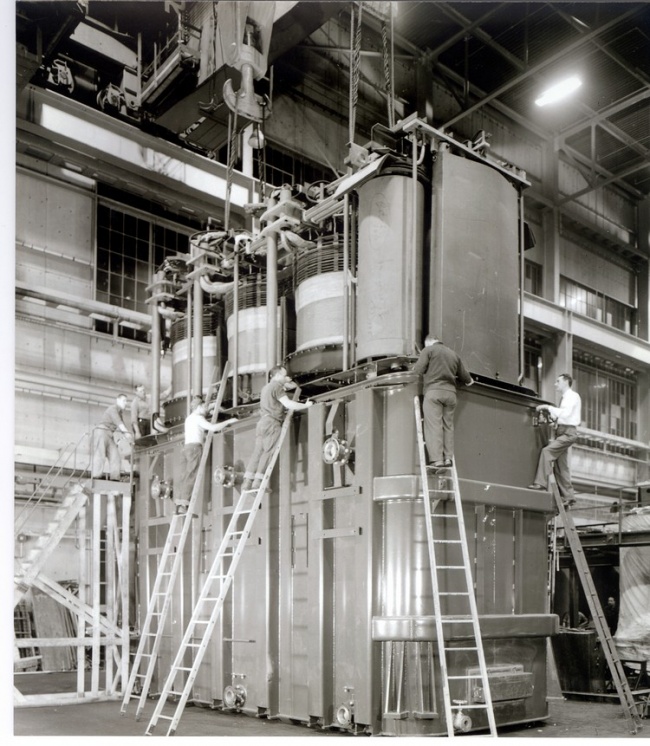

| [[Image:Blalock - page 145.jpg|thumb|center|650px|Building 9 High Bay (1949)]]

| |

| | |

| The impulse and 60-Hertz capabilities of the various test areas (in 1949) were as follows:

| |

| | |

| {| cellspacing="1" cellpadding="1" border="1" width="525"

| |

| |-

| |

| | '''Location'''

| |

| | '''Area'''

| |

| | '''Kv-AC'''

| |

| | '''Kv-impulse'''

| |

| |-

| |

| | High Bay

| |

| | 1

| |

| | 1050

| |

| | 5100

| |

| |-

| |

| | High Bay

| |

| | 2

| |

| | 700

| |

| | 5100

| |

| |-

| |

| | Low Bay

| |

| | 3

| |

| | (high current generator)

| |

| |

| |

| |-

| |

| | Low Bay

| |

| | 4

| |

| | 300

| |

| | 1200

| |

| |-

| |

| | Low Bay

| |

| | 5

| |

| | 300

| |

| | 750

| |

| |-

| |

| | Low Bay

| |

| | 6

| |

| | (lightning arrester test)

| |

| |

| |

| |-

| |

| | Low Bay

| |

| | 7

| |

| | 300

| |

| | 600

| |

| |-

| |

| | Low Bay

| |

| | 8

| |

| | 100

| |

| | 200

| |

| |-

| |

| | Low Bay

| |

| | 9

| |

| | 150

| |

| | ----

| |

| |-

| |

| | Outdoor

| |

| | 10

| |

| | ----

| |

| | 5100

| |

| |-

| |

| |}

| |

| | |

| The high current generator in Area 3 was the original 1934 device. It had been moved and re-worked in its configuration. Later on, it was moved to the High Bay and installed in the southeast corner. This became known as "Area 14".

| |

| | |

| Area 5 was referred to as the "air-conditioned room". The walls, floor, and ceiling were thermally:- insulated, and access was via refrigerator-type doors. There was a large double door of this type for moving large equipment into and out of the room. Personnel access was via a small door of the same type leading to an adjacent control room. Large Thermopane windows allowed for observation of tests from this control room as well. The room was capable of providing temperature ranges of 0°F to 100°F, over a wide range -of controlled humidity levels. This was_to allow for the testing of insulation components and structures which had to perform in a variety of climatic conditions.

| |

| | |

| The Building 9 test facilities were primarily intended for use in high voltage development work on all forms of insulating structures and transformer-related devices. The majority of such work involved the determination of the voltage withstand capability (both impulse and 60-Hertz) of insulator strings and bushings. However, a great deal of development work relating to new designs of lightning arresters was carried out as well over the years.

| |

| | |

| In 1965, the High Voltage Laboratory constructed a fifty foot high "portable" impulse generator. Its main usage was at Leadville, Colorado where an extensive series of tests was carried out to determine the flashover strengths of various types of insulating structures at very high altitudes (atmospheric pressure is a factor in this regard). Walt Duda, Hans Morf, and Granville G. ("Pete") Kemp of the Laboratory were instrumental in the design, construction, and operation of this device.

| |

| | |

| Also very much involved in this project was "Ted" Brownlee. Ted retired from the Laboratory in 1968, after a forty-four year career at Pittsfield G.E. Ted had graduated from Rensselaer Polytechnic Institute in Troy, New York in 1924. He worked with Dr. Karl McEach- ron in Pittsfield and assisted with setting up the first high-speed cathode ray oscillograph in the country for recording lightning-type discharges. Ted worked with Julius Hagenguth in planning the operation and design of Building 9. Eventually, he became a Fellow in the Institute of Electrical and Electronic Engineers (IEEE), having written a total of five technical papers on the subjects of lightning and high voltage testing.

| |

| | |

| A great deal of production-type testing was also performed in Building 9 over the years. This occurred whenever the "factory" test facilities normally used to perform this type of work became overloaded, or when new, higher voltage products were being built which had test requirements that exceeded the production test area capabilities. Much testing of high voltage bushings was carried out in Building 9 over the years for these reasons.

| |

| | |

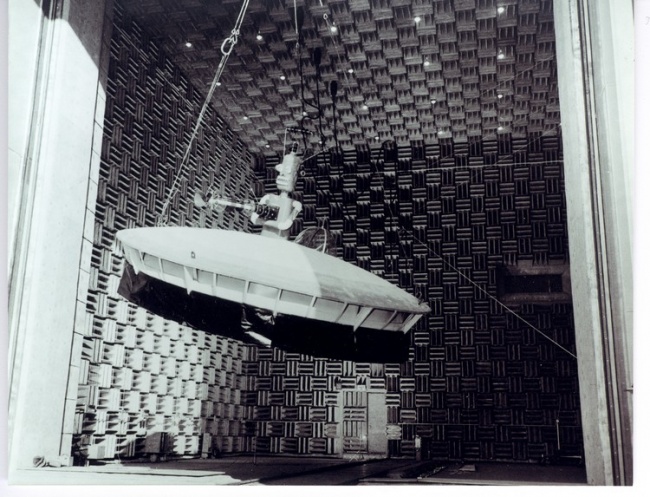

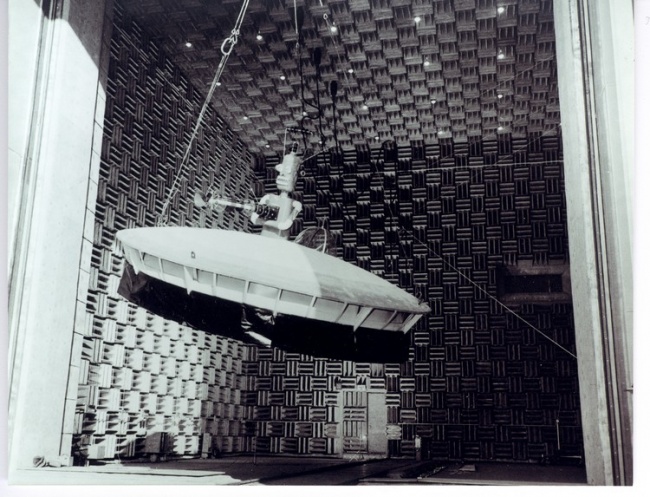

| In addition, over the nearly forty year history of Building 9, a great deal of highly specialized, and often very fascinating, testing was carried out on very unusual types of equipment, both for industry as well as for the United States Government. This included a series of tests for the National Aeronautics and Space Administration (NASA) which involved the protection of rockets on launching pads at Cape Canaveral (now Cape Kennedy) in Florida from lightning strikes. Florida has one of the highest incidence rates for lightning in the country.

| |

| | |

| Also, beginning in the late 1960's, the old (1934) high current generator in the corner of the High Bay was put into service for the investigation of effects related to lightning strikes to aircraft. Primarily, this work was performed for the United States Air Force. The need for it arose because new "composite" type materials had been developed for use in airplane construction which were lighter than conventional aluminum construction. Unfortunately, these materials do not provide the "shielding" effect from lightning surges which metals such as aluminum do. This problem was compounded by the increasing use of delicate computerized electronic equipment on airplanes which is very susceptible to damage from such surges. At one point in time, an actual Air Force fighter plane wing was brought into Area 14 in the High Bay. Impulse currents from the high current generator were discharged through it, and the induced surge voltages on control wiring within the wing were measured. Larry Walko, of the Laboratory engineering staff, conducted this work. Subsequently, he went on to continue such work at the Wright-Patterson Air Force Base in Dayton, Ohio.

| |

| | |

| [[Image:Blalock - page 148.jpg|thumb|center|650px|Air Force wing and High Current Generator courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 149 (top).jpg|thumb|center|650px|Building 9 in 1949, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 149 (bot).jpg|thumb|center|650px|Building 9 in 1996 photo by author]]

| |

| | |

| [[Image:Blalock - page 150 (top).jpg|thumb|center|650px|High Bay area of Building 9, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 150 (bot).jpg|thumb|center|650px|Low Bay area of Building 9, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 151 (top).jpg|thumb|center|650px|Area 5, the "air-conditioned" room, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 151 (bot).jpg|thumb|center|650px|The Building 9 motor—generator room, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 152 (top).jpg|thumb|center|650px|The 3.6-MV portable impulse generator, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 152 (bot).jpg|thumb|center|650px|A 60-Hertz flashover in the High Bay, courtesy of General Electric Company]]

| |

| | |

| === Outdoor Test Area ===

| |

| | |

| As power system voltages rose higher and higher, high voltage testing requirements rose as well. Thus, eventually, even the generous testing space of the Building 9 High Bay was not sufficient for the highest voltage tests which had to be performed. This was true especially for switching surge impulse tests. These discharges had a habit of seeking far off points of termination, such as the walls of the building!

| |

| | |

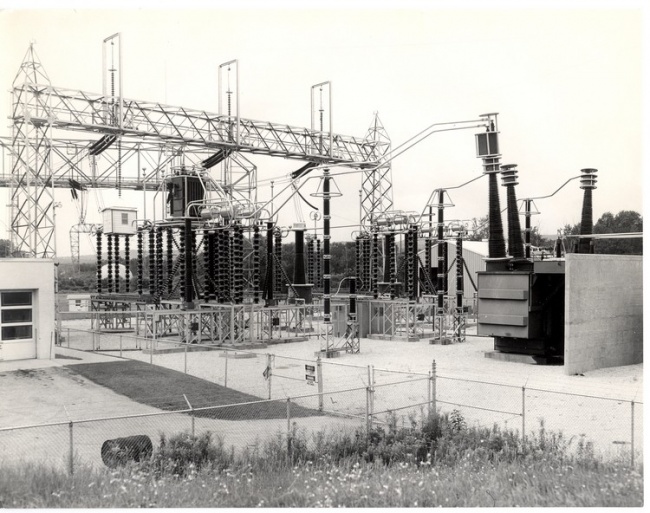

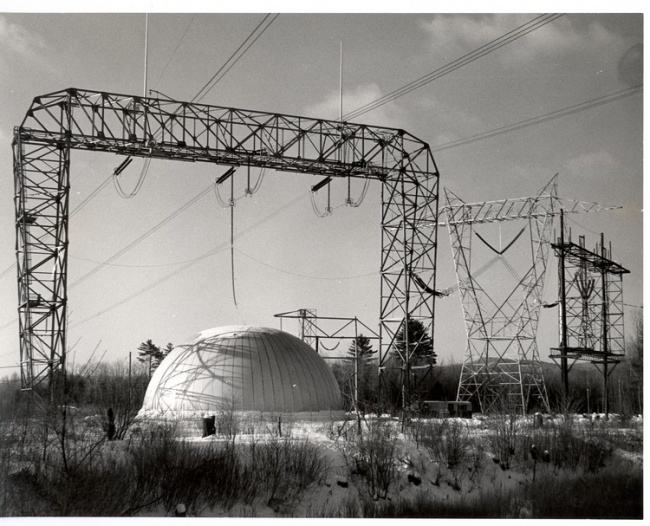

| Accordingly, in 1968, a new outdoor testing facility went into operation near Building 9. This came to be known as "Area 72" since the building which served as control house, office, and work space was designated as Building 72 according to the plant's building numbering scheme. This was located east of New York Avenue and north of Merrill Road, east of the plant. It is the space now occupied by the Pittsfield Generating Company's co-generation plant.

| |

| | |

| An impulse generator was designed for Area 72 which. featured an enclosed inner stack for protection against the weather. Dry, filtered air was blown up through this stack in order to maintain the ability of the generator to withstand the high voltages produced during its operation. Originally, the generator was designed to be able to produce discharges of up to 7200-kv. However, it was never actually built up higher than was necessary to produce an output of 5000-kv. As such, however, it stood eighty feet tall and was braced to withstand a wind load of up to 75 miles per hour.

| |

| | |

| A very notable feature of this generator was that it was equipped with an internal elevator which rose up through the enclosed stack. This was a decided convenience for the operators when changing circuit connections in the generator or performing necessary routine cleaning operations.

| |

| | |

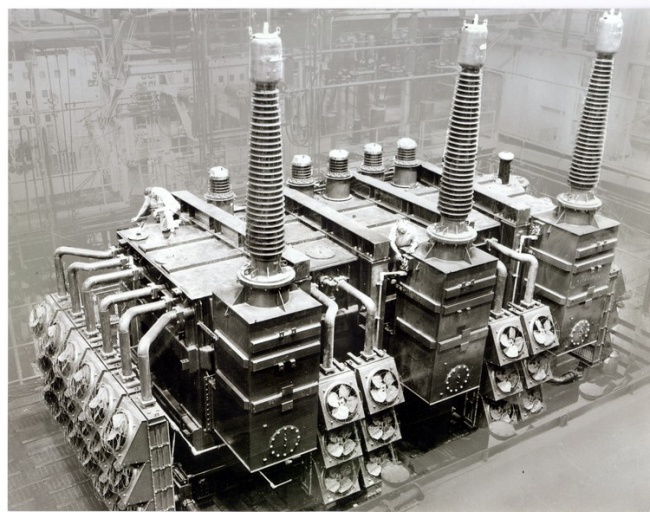

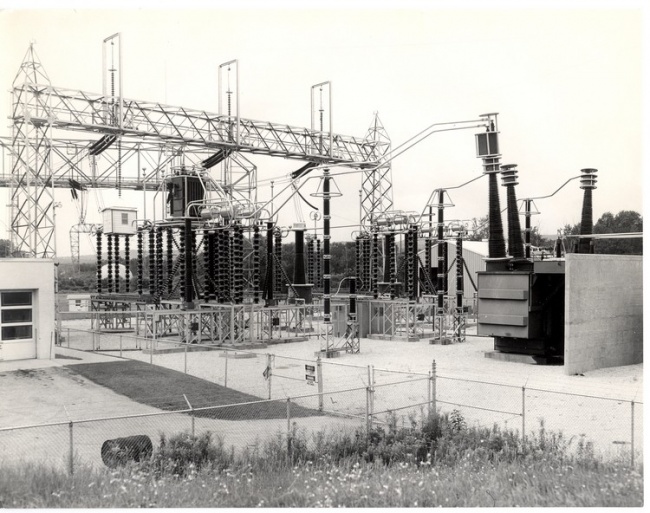

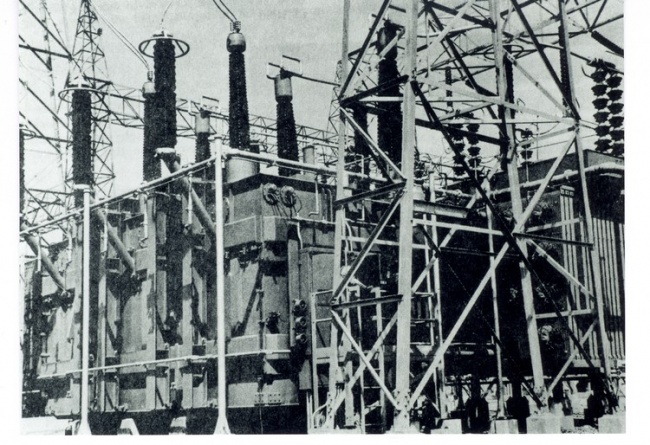

| Area 72 was also equipped with three 500-kv cascade transformers which allowed for 60-Hertz testing up to 1500-kv. For the testing of large bushings whose lower ends had to be immersed in oil, a cylindrical tank was used which was 25 feet high and 20 feet in diameter. This tank contained 52,000 gallons of 10C oil (transformer oil).

| |

| | |

| There was also a large "H"-frame steel transmission line tower which was used for flashover level testing of various insulator string configurations.

| |

| | |

| When Pittsfield transformer operations ceased in 1987, the Area 72 impulse generator was dismantled and moved to Project UHV on East New Lenox Road. There it was re-assembled and is still being used for impulse testing purposes by EPRI (Electric Power Research Institute) which now operates that facility. The other Area 72 equipment was either re-located or scrapped.

| |

| | |

| [[Image:Blalock - page 154.jpg|thumb|center|650px|Area 72 tower for insulator testing, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 155 (bot).jpg|thumb|center|650px|Area 72 impulse generator, courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 155 (top).jpg|thumb|center|650px|Cascade transformers and bushing test tank courtesy of General Electric Company]]

| |

| | |

| [[Image:Blalock - page 156.jpg|thumb|center|650px|"Wild" switching surge flashovers in Area 72 (multiple exposure), courtesy of General Electric Company]]

| |

| | |

| == Chapter 10: Impulse Testing ==

| |

| | |

| Proper impulse testing requires that a surge of a known voltage magnitude and a definite duration (about 100 microseconds total), and having a known polarity, be produced on demand. Early attempts at impulse testing were crude in regards to all of the above!

| |

| | |

| F.W. Peek, Jr. was a pioneer in this field. In a paper for the American Institute of Electrical Engineers titled "The Effect of Transient Voltages on Dielectrics" and published in the AIEE Transactions of September 16, 1915, Peek described the following circuit which he used to produce impulse type waveforms:

| |

| | |

| where: Rw = water tube resistance L = single layer coils C = tin foil and glass plate capacitors

| |

| | |

| According to Peek, this arrangement occupied about a ten foot by twelve foot area. With sufficiently high values of resistance, the normally oscillatory circuit would be overdamped and just one surge wave would be produced. Because of the A.C. excitation, however, the polarity of this surge could not be predicted!

| |

| | |

| The basic frequency of the surge, which determined its duration, was a function of 2L, C/2, Rw, and the effect of the test piece.

| |

| | |

| The sphere-type spark gap would break down at the crest of the applied 60-Hertz waveform. It acted both as a switch, initiating the surge, and as a crude form of voltmeter to determine its magnitude.

| |

| | |

| In 1925, however, a circuit known as the "Marx" impulse generator (named after its inventor) was developed. This was an ingenious means of charging a bank of capacitors in parallel, to some moderately high D.C. voltage, and then discharging them in series in order to multiply this voltage by the number of capacitors in the bank. Thus, surges of very high voltage, and of known polarity, could be produced.

| |