Oral-History:Jerry B. Minter

About Jerry B. Minter

Jerry B. Minter was born in 1913 and became interested in radios at an early age. In 1922 he saw an early crystal set, and in high school he was already helping to install and service radio sets. He studied for one year at North Texas Agricultural College in Arlington and then went to MIT where he graduated in 1934 with a degree in electrical engineering. After graduating, Minter got a job at Boonton Radio in New Jersey, and then he helped to start Measurements Corporation in 1939. After the war, Minter and his company began working with television, including the Model 90 signal generator and later with developments in television color. He also became involved with connectors, and in the 1960s Minter worked on medical instrumentation which involved videotaping output from surgical microscopes. Minter has twenty-six patents, six of which are for recent work in aviation, another field he was involved in. He was very active in the IRE in his early career, helping to found the North Jersey Subsection – which became a section in 1954 – and serving as its first chair, and he also helped found the Audio and Engineering Society.

In his interview, Minter discusses many aspects of his long and still very active career. He explains how one of his signal generators was at Pearl Harbor on the day of the attacks and the controversy over mechanical versus human failure. He also talks about the formation of the North Jersey Subsection, working with J.W. McRae, its early chairs (such as Allan Parkes, Jr., J.F. Morrison, Gordon McCouch, Tom Goldsmith and George Holst) and the later merger of AIEE and IRE into the IEEE. Throughout the interview, Minter discusses the difficulties of military work and the issue of classified information particularly during the war. Minter also shares his experiences with Governor Charles Edison, son of Thomas Edison, and the stories Edison told him about his father and Henry Ford.

Jerry Minter’s interview is a particular milestone for the IEEE Oral History project because it is the first one to be videotaped – appropriate with his involvement in television and video for so many years.

About the Interview

JERRY B. MINTER: An Interview Conducted by Michael Geselowitz, IEEE History Center, 13 March 2007

Interview #470 for the IEEE History Center, The Institute of Electrical and Electronics Engineers, Inc.

Copyright Statement

This manuscript is being made available for research purposes only. All literary rights in the manuscript, including the right to publish, are reserved to the IEEE History Center. No part of the manuscript may be quoted for publication without the written permission of the Director of IEEE History Center.

Request for permission to quote for publication should be addressed to the IEEE History Center Oral History Program, IEEE History Center, 445 Hoes Lane, Piscataway, NJ 08854 USA or ieee-history@ieee.org. It should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Jerry B. Minter, Electrical Engineer, an oral history conducted in 2007 by Michael Geselowitz, IEEE History Center, Piscataway, NJ, USA.

Interview

Interview: Jerry B. Minter

Interviewer: Michael Geselowitz

Date: 13 March 2007

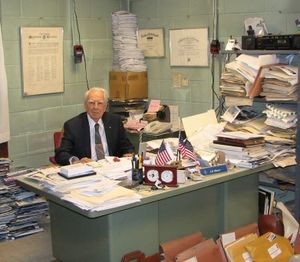

Place: Components Corporation in Denville, New Jersey

Components Corporation

Geselowitz:

We're here with Howard Leach, the History Chairman of the IEEE North Jersey Section, to conduct a video history interview with Mr. Jerry Minter. Jerry, if I might, I'd like to start with the present before we go into your deep past. Could you tell us a little bit about Components Corporation and what you do here?

Minter:

Components Corporation makes test electrical connectors that are highly reliable and widely used in the industry. We have our own machinery for forming them, and one of the secrets of them is they are heat-treated. The beryllium copper we use is completely soft when we form it and we heat-treat it after forming to get the full benefit of the hardness and life of the material. When beryllium copper is properly heat-treated it has an almost indefinite life. Up to a certain fracture point it could be broken of course. We went close to the fracture point and found out that the Goddard Space Flight Center had also done this - they had plugged in the unit, in and out, a million times and it still made good contact. When we heard this we could hardly believe it, so we made our own test set and checked it. The connector withstood a million insertions and it was still good.

Geselowitz:

Even though it was your product you didn't believe it.

Minter:

We just wanted to be sure we heard the story right.

Geselowitz:

And they are still manufactured here in New Jersey and shipped around the world.

Minter:

Yes. It's interesting about manufacturing in New Jersey, since you brought up the subject. We use beryllium copper, which is heat-treated and plated, and it's now against the law to do plating in New Jersey.

Geselowitz:

For environmental reasons.

Minter:

Because it pollutes the water supply. Consequently, we send all our material out to be plated and then get it back. We lost most of our New Jersey customers that used to do plating because they're out of business. Many of those who used the plated parts moved out of state, so we don't sell much in New Jersey anymore.

Education, radio work

Geselowitz:

I'd like to get back to the story of the early components and the testing, but first I'd like to take you all the way back to the beginning. How did you become interested in engineering as a young person? I'd also like to hear a little bit about your education.

Minter:

When I was in high school I helped install and service radio sets. That was 1928-29. Prior to that, in about 1922, I saw one of the early crystal sets. I was only about 10 years old then.

Geselowitz:

You were born in 1913?

Minter:

Yes. I saw the set and thought I would try to build one. I had trouble - I couldn't build it. Finally, I bought my first crystal set and then built one. Later I learned what was wrong. I had not realized that the coil form had to be nonmetallic and I had used a metal tube to wind my coil. That doesn't work.

Geselowitz:

That was when you were 10 years old and by the time you were 15 you were able to service radios as a part-time job during high school.

Minter:

Yes. I worked for a fellow that had a shop. I couldn't drive a car because I was too young, so when customers were out in the field he would drive me around to service them. When I got out of high school in 1930 I wanted to go to MIT, but I was too young since I was only 16 and you had be 17. I went one year to a local school, North Texas Agricultural College in Arlington, Texas. I did radio servicing during that summer, then I went to MIT and graduated in '34.

Geselowitz:

What was your course of study at MIT? Electrical engineering?

Minter:

Electrical engineering, and I specialized with a communication option. In those days there were vacuum tubes but no solid-state parts. We didn't have very good equipment, so I had to build some of my own test gear to do the laboratory experiments, but I had a very good year. I learned a lot of good mathematics and basic fundamentals at MIT, and met a lot of people that were important later on. It was a good place to be in those days.

Geselowitz:

You went from Texas to Cambridge, Massachusetts.

Minter:

That's right.

Boonton Radio

Geselowitz:

Where did you go to work when you graduated?

Minter:

When I graduated I went back to Forth Worth to get a job. That was during the Depression and things were really tough. I could repair radios and stuff like that, but I wanted a permanent job. I had a ham station, 1EQC, and I used my ham call and got somebody in Boonton that told me about a company called Boonton Radio. I drove all the way up to New Jersey and got the job for $15 a week. We worked half days on Saturdays, in the morning. It was about a 40-hour week. Boonton Radio made a Q Meter which measured the quality of coils, called the Q factor. I got a very good background making test equipment and helping to install and service radios for the customers. Later on we started our own company, just before the war in 1939. Our boss had died and we didn't get along with the owner that took over so we started our own company, Measurements Corporation, in '39.

Measurements Corporation

Signal generators and Pearl Harbor

Geselowitz:

Where was that located?

Minter:

That was also in Boonton. We started in my dining room in Mountain Lakes and we got thrown out. We found out that was illegal. We didn't stay in the dining room very long.

Geselowitz:

I take it it was not zoned for commercial use.

Minter:

That's right. We rented space down in Boonton in an old factory building. During the war we had up to a hundred people working for us making signal generators. A signal generator is a radio transmitter used for testing receivers, and there were special ones for radar. Radar was a new thing in those days and required a special kind of test gear, and a signal that could be turned off and on, like television. Television had just started, but it wasn't well known during the war. However, the principles that were used in television were used widely in the signal generators that we made for testing radar. Radar of course was a big factor in the war. Then we also designed the megacycle meter model 59 a little grid dip meter. It's a meter for measuring frequency. It puts out a signal and when the signal is absorbed the meter dips down and shows you it’s resonant frequency. You can measure a frequency of something just by putting this close to it and coupling it in so that you can measure what's happening on a bench dynamically. If you make a mistake in something the frequency will be off. We made these in very large quantities. It uses a little coil to plug in to change frequency ranges to go to very low and very high frequencies.

Geselowitz:

Were you doing this for the military effort during World War II mainly?

Minter:

It was used by people who had military contracts and we sold some to the military. As a matter of fact, our signal generator was in Pearl Harbor, and when they were bombed our generator was there servicing the radar set that saw the plane.

Geselowitz:

The one at the Opana Station.

Minter:

They saw the plane and reported it, but the guys ignored it and said, "Oh, that's our people." Our test set was on the spot.

Geselowitz:

You were part of a very important part of history. That's very interesting, because actually that radar installation is an IEEE Milestone, and there was some controversy when it was brought to the IEEE. Some people said the radar failed because the Japanese planes flew over and attacked, then people found out it was a human failure. The set worked exactly like it was supposed to, and the people ignored the information.

Minter:

That's right. We had a test generator that would simulate the plane. In other words, it was a signal generator that would generate a signal like the plane was generating and you could see whether the system was working properly or not. In fact all parts could be checked – the antenna and the whole thing. They knew it was working, they saw the plane and reported it. The guys to whom they reported just ignored it, saying, "Oh, that's got to be our planes."

Geselowitz:

Right. They didn't want to believe it.

Minter:

Unbelievable.

Military collaborations, WWII

Geselowitz:

For your work during the war with the signal generator you were just talking about, did you do the research, development and production in Boonton?

Minter:

That's right. There were some things we had to buy outside. For example, we bought the big heavy power transformers from people who were in the business. We didn't make all the parts - where we could buy something we bought it. We bought the vacuum tubes too.

Geselowitz:

Right, but I meant the final equipment. Did you interact with the people at Fort Monmouth?

Minter:

Yes, very closely.

Geselowitz:

How about the lab at MIT? Did you have any contacts at the Rad Lab?

Minter:

It's a funny thing about MIT. I knew the people up there and they were very good friends of mine, but they acted as though I was not cleared for security. Very strange. I mean, here I had security clearance with the Navy, Army and Air Force. At Wright Field I walked in like I owned the place, and with the Navy it was the same, and Fort Monmouth were very good friends. I knew everybody there from Commander on down. We used to go out where they had the big rigs on the beach and a boat out at sea. We made special test gear just for them. In fact it was that test gear that was in Hawaii.

Geselowitz:

Right, because they made the SCR 270.

Minter:

It was in service and working. We were very close with them. We worked with some of their customers too. We worked with all people that had clearances.

Television, Model 90

Geselowitz:

How did your work change after the war?

Minter:

Television came along, and we developed the Model 90 television signal generator. We developed it ultimately for color. Before that we made video generators that could just test black and white systems. We had television during the war of course, and we made very simple test gear for that. In other words, just quick tests for if it worked, yes or no, and not testing quality. It's one thing to just turn it on and off or see how good it is. We made good signal generators for them later that could check the quality for music if you used music - it was that good that you could put music on and get good music out on the military equipment. When the war broke [sic; ended] they went over to TV. TV began to build and we built television test equipment.

Geselowitz:

Did you work with Sound Lab down in Princeton, New Jersey?

Minter:

Yes, we did. We worked with RCA very closely, with people in Chicago and all over the country. We made signal generators that simulated TV transmitters so that receivers could be tested for quality on a proxy line. We made thousands of those. Model 65B. It was not TV, but the successors to that in the line became TV generators and one you saw outside was the one for color.

Geselowitz:

When color TV finally came in.

Minter:

That's right.

Geselowitz:

It took a while to penetrate the consumer market. I know that the work was actually done earlier, but the sets were expensive.

Minter:

That's right.

IRE

World War II; conferences and papers

Geselowitz:

I'd like to turn now from the actual technology to the profession. Thanks to the explosion in World War II of all the work you talked about and all the engineers up at MIT and the Harvard Lab, and down at Camp Evans, after the war there was a real boom in electronics in the world, particularly in this country, and especially in New Jersey. Of course you mentioned before the transistor was invented Bell Labs decided to go over to solid state. The main membership organization or association for radio engineers was the Institute for Radio Engineers, the IRE.

Minter:

That's right.

Geselowitz:

It's one of the predecessors of the IEEE, with which we are all affiliated today. I know that you were very involved in the founding of the North Jersey Section of the IRE and I want to come back to that in a minute, but would you say something to us about how you first got involved with the IRE?

Minter:

We gave papers. If we wanted to present a paper we had to go to New York because the meetings were in New York. I was having quite a lot of trouble with New York City parking, etc. J.W. McRae was on the IRE Board of Directors at that time I think, and he was also "Mr. Murray Hill." Murray Hill had just been set up and had all-new equipment. They had a beautiful laboratory and sound room, but it was all classified. Military.

Geselowitz:

Was that AT&T's Bell Laboratories?

Minter:

Yes, Bell Laboratories at Murray Hill. He got them to declassify for us so that we could go in there even though it was a military space. They would secure the military stuff and put it to one side. Later of course there was no military to worry about, but when the war first started there was military gear there so we had to be careful about security. However they were very cooperative. Then of course we used the IT&T lab in Nutley and there was one down in Springfield. There were various laboratories and facilities we were able to use for our meetings. We had up to a hundred people attending our meetings. Obviously we could not give out military secrets, but we gave nonmilitary information.

Geselowitz:

What did you feel was the advantage of giving papers and exchanging information at those conferences?

Minter:

I guess you'd say education. We all had gone to school and learned the fundamentals, but we were learning at that time many things we didn't know before that were not military or classified. We had to be careful about security during the war, but as the war broke [sic; ended], and security became less of a problem, we could be more open. Of course TV opened up more things and then color TV came on top of that which further complicated things. Black and white was bad enough; the color was much more difficult.

Geselowitz:

Yes. I am interested because it was in 1944 - right after the war - that the IRE decided to allow subsections - prior to that everything had to be in one section. New York was the largest section and it was growing too big for its own good because of all the developments that happened during the war, as you said. The first subsection was actually the Monmouth subsection in Central and Southern New Jersey.

Minter:

You're right.

North Jersey

Geselowitz:

That was in 1944. What companies were the people in Northern Jersey working at in 1947 that they felt they needed their own subsection and didn't want to go into New York?

Minter:

Bell Laboratories was one. IT&T was another. There were several companies that are no longer in business in this area that had big workforces, and some of them had auditoriums that we could use. The Monmouth group was not well organized, and was quite a ways from North New Jersey and didn't have many meetings, so Monmouth was not very successful as a subsection. McRae suggested we found our own full section and helped me with the paperwork.

Geselowitz:

Was that because he was active on the IRE Board and felt that there were enough engineers in the region?

Minter:

I think he was Treasurer of IRE. He had charge of the money. He also helped the Long Island group form their section.

Geselowitz:

They formed their own section around the same time. Yes.

Minter:

Yes, at the same time. He got us both started.

Geselowitz:

That's interesting. Once you became a section, what did that enable you to do?

Minter:

First of all, we were covered in the publications more completely. We got a bigger publication because we had more material to put in. That was one thing we did right off the bat. They broke it down into subsection papers and we had a small section for North Jersey, papers published in New Jersey later on made it into main headquarters. The same thing happened to Long Island. The whole area expanded.

Geselowitz:

In the early and mid-'50s when you were a growing subsection and then later a section, how often did the North New Jersey group meet?

Minter:

Probably every other month during wintertime. We did not have meetings in the summer. Sometimes we had a special meeting for a special occasion. I recall when we had some special meetings that involved the space system and some of the space equipment that was built in New Jersey. And of course that eventually got into publication. We got into a new field or area that we would not have gotten into if we had not had the facilities here to do it. The whole field of television opened up too, and we built equipment specially made for testing color television sets.

Committee activities

Geselowitz:

How much were you personally involved in IRE the big organization, the parent organization? The headquarters is right over here in New York. It's not that far. Did you get involved in the Standards Board?

Minter:

I was on various technical committees.

Geselowitz:

What technical committees were you most involved in?

Minter:

Standardization of electronic measurements. We had developed a Q meter – I didn't build it by myself, but I helped build it – that helped determine the quality of coils at one of my first jobs involving radio. We did things that involved the Q meter and it got more involved as we had television color which had to be taken into account. There were many things that had to be done to modify our test equipment. We got involved locally in that, and that got published in the nationwide magazine as well.

Patents

Geselowitz:

How involved were you in the television standards? That was a very political development because the potential consumer value was so great that there were a lot of competing parties.

Minter:

I was involved to some extent, but mostly technically. I didn't consider myself an optics specialist, so I didn't get into the optics end very much. I saw what was done by others, but didn't try to patent anything myself. I did get a few patents, however, in radio. I have twenty-six patents altogether now. Most recently I have a patent which we presented a paper on back on the 13th of December [2006], before the North Jersey Section. The patent is for an invention that makes it possible to detect anyone that is flying an airplane and quite a few miles away automatically if they are at relative altitude by merging differential time of arrival of two closely spaced antennas. I have six patents on that just issued a couple of years ago and I'm trying to get a license now to produce this for use in every airplane.

Geselowitz:

Would this be for commercial aviation or air traffic control purposes?

Minter:

The idea is that this thing will give a warning. It will flash a red light or signal stereo headphones. Out of the six patents five of them are how to tell the pilot where something is out there. It's a complete area measurement, whether in front or behind.

Geselowitz:

You are still active in research and development and inventing.

Minter:

Yes. In fact we built one and demonstrated it here in Morristown. We observed through a window the aircraft taking off from the airport.

Geselowitz:

You are obviously still technically active and executing patents.

Origins of Components Corporation; connectors

Geselowitz:

During this time we were just talking about in the '50s, when the IRE subsection was growing and became a section, what work were you doing then and where?

Minter:

In 1950?

Geselowitz:

In 1950 through '55.

Minter:

I was with Measurements Corporation. Not this company.

Geselowitz:

Was that still in Boonton, New Jersey?

Minter:

Yes.

Geselowitz:

How did you come to join Components Corporation?

Minter:

Three of us owned Measurements Corporation and we sold it to the Edison Company. I did not deal directly with Governor Charles Edison, until later on, but it was his company. The Edison Company moved the manufacturing up to New England and I got out of that business altogether. Then I got involved in making connectors and so forth.

Geselowitz:

How did you get involved with connectors?

Minter:

We got involved by building them ourselves, and I guess the answer was that we were making test equipment, and we found that you need to have connectors to plug in things. The connectors that were being manufactured were not very good from the standpoint of reliability and they were big physically. Many of the connectors were not even heat-treated. They just made them out of spring brass. After a few connections they started to lose contact. Tube sockets for example were all made out of ordinary material. If the tube is only plugged in once or twice you can get away with that, but if a tube is plugged in several times the contacts start to get damaged – in those days anyway. We made a much smaller unit out of beryllium copper that we heat-treated so the springs would last indefinitely. We had better contacts so that things plugged in were more reliable. During the war we had contacts through the military, people making military gear. Many companies were in that business. IT&T was a big one.

Geselowitz:

How did you come specifically to Components Corporation?

Minter:

We decided to start up a company to build these things ourselves after we sold the Measurements Corporation.

Geselowitz:

The same partners who sold Measurements Corporation came with you?

Minter:

That's right. One or two came along, and some of the equipment, test gear and machinery.

Leaders in the North Jersey Section, IRE

Geselowitz:

Interesting. Before I follow the story of some of the more interesting recent work that Components Corporation is doing I want to go back and talk about the North Jersey Section a little more. Even though you mentioned that McRae was really the person behind the scenes, you were the founding chair of the subsection initially.

Minter:

That's right.

Geselowitz:

Let's talk about some of the other people who helped you form the section who some of the early chairs. Allan W. Parkes, Jr. succeeded you as the next chair.

Minter:

Allan Parkes was with Aircraft Radio, a company that made military gear for the Navy. They were a good-sized outfit during the war and good friends of mine. They only made things for the military though. They didn't make any commercial equipment. He was a field engineer for them, so he went out and arranged the contracts and came back to the lab. He was in between them and their military customers. He lived not very far away from me in Mountain Lakes, so I knew his family and we were good friends. When I bought my first house he helped me with the paperwork.

Geselowitz:

How about the next chair, J. F. Morrison?

Minter:

Morrison lived in Boonton and was with Bell Labs in Whippany. I remember we had a very classified meeting there. To get in Whippany was a job. We had a lot of problems with that. We did have a meeting there during the war though, and he helped us get the facilities. There was some stuff they were doing that was not military but classified. Morrison was very nice and cooperative - he helped with getting papers from military people on material that was not classified. We actually had one meeting there, but we had so much trouble.

Geselowitz:

It was so difficult you didn't bother to try again?

Minter:

We didn't bother anymore. Too much classification.

Geselowitz:

How about the next chair, Gordon McCouch? Did you know him?

Minter:

Yes. I'm trying to think.

Geselowitz:

It was under his leadership in '54 that the subsection became a section.

Minter:

Yes. I'm trying to think of what all he did. I don't remember all the details, but he was very active. I did not know him too well personally.

Geselowitz:

How about Thomas Goldsmith?

Minter:

Tom Goldsmith was one of the pioneers of DuMont. He was a very nice chap and a very good friend of mine. We had DuMont sponsor several things with technical papers on what they were doing in video equipment. They pioneered the TV cameras. RCA actually had to bow down to DuMont because RCA didn't know as much about building these things as DuMont did, so they worked with RCA in the very beginning. We had some technical papers on the problems.

Geselowitz:

On these early television cameras.

Minter:

Color created all kinds of problems. As soon as it went to color there were many more complications than ever were experienced with black and white. DuMont was very helpful in color. They made the first color equipment.

Geselowitz:

That's right, they did – though RCA eventually developed the whole system that took advantage of it.

Minter:

That's right.

Geselowitz:

How about George Holst? Did you know him?

Minter:

Yes. He was with IT&T. George got us quite a few contacts that were in the military and not classified. There was a lot of gear made for military work that was not really classified. He was able to help us on that score.

Geselowitz:

How about Alanson Parkes?

Minter:

He was with Aircraft Radio, and that was all pretty much military gear. He was very good, and I think he gave a paper one time. They made receivers and transmitters, most of them airborne or air-transported. In fact they were around long before the war, in the '30s.

Geselowitz:

Alanson Parkes was actually the chair when the IRE merged with the AIEE to form the IEEE.

IRE and AIEE merger to form IEEE

Geselowitz:

Would you say a little bit about your memories of the merger? How did it feel to have these power engineers from the AIEE all of a sudden showing up at your meetings? Was there a culture clash?

Minter:

I don't remember a clash. The auditorium on Bloomfield Avenue was owned by one of the power companies, and they let us use the auditorium before they had anything to do with us because many of them were in radio. We had bridges like that from working with people that were in the business, so they helped us by giving us auditorium space. When they became part of us they gave us the technical papers too. However we were a separate deal in the beginning.

Geselowitz:

Interesting.

Medical instrumentation; surgical microscope

Geselowitz:

Actually the merger was in part indicative of changes in the technology brought on by the electronics revolution, so I want to get back now a little bit to the technology side. You mentioned earlier some medical applications. Could you talk a little about some of the instrumentation work that you did in the '60s both with space and medical?

Minter:

Yes. The medical work we did, in general, was to videotape the output from a surgical microscope. Eye surgery for example was getting to be quite a thing. Inserting a lens in the human eye would take place with a bad lens. That technology was put on videotape by equipment that we supplied, and we had meetings where we would have fifteen or twenty doctors spend two days with two or three patients. We also had viewing cameras in another room because you can only get a few people around a microscope. We had maybe fifteen or twenty people in the auditorium watching a monitor which we supplied and videotaped it so they could take a videotape back home if they wanted.

Geselowitz:

This was a way you could demonstrate something such as microsurgery and have people see it while also preserving it, capturing the record by videotaping it so that people could take it with them for educational purposes.

Minter:

That's right. In fact we installed an overhead. We spent a lot of time in surgery suites satisfying all the security and health hazards. We had to be sure it was absolutely clean, could be kept clean, keep our linens from getting spattered with anything that they sprayed around and so forth. We spent quite a bit of time in the surgery area. In some cases we actually suited up and worked alongside the surgeons to help them with the camera. We had the surgeon run the camera because we weren't experienced using a microscope. In some cases we couldn't use a microscope. It involved surgery itself. Therefore we needed to have more than one microscope. Two guys would be doing it at a wide angle and a narrow angle simultaneously. You don't get repeat surgery; it's only done one time. You can't rerun it.

Geselowitz:

What led you to that? That's a very important application, and obviously bioengineering became a growing field in the '60s and even more in the '70s. What led you, with the background you have already described, to get into that particular application of video and television?

Minter:

I suppose in my business I knew some guys in optics and fitting lenses. They were planning to have meetings and they said, "How about videotaping us?" We had just gotten videotape equipment. We had no way to do it yet, so we had to get an adapter that would fit on the side of the microscope. We got a special adapter that would fit onto the microscope so we could tie on our camera and take it right off the microscope feed. It was made in Switzerland I think. We did that for one of the doctors we knew very well. He paid for the thing of course. We knew several doctors that were involved in various areas of surgery. Most were in eye surgery, but some got involved in intestinal surgery. We supplied cameras and actually installed them permanently in the building itself. They had a special setup to play them back in the auditorium in their teaching areas. We got involved quite a bit in various hospitals. As they built new hospitals they wanted to make facilities available for the video.

Color was very important – most important – in surgery. That was at the time that color was beginning to become popular, so we had to give them the latest in color gear and it had to be small and easy to use. It could not be the big and heavy three-camera things; it had to be all one little package. We pioneered supplying these to doctors for their meetings and helping them learn how to use the equipment and making copies for them later. Later people went into that business, but we didn't. We only did it as accommodation.

Geselowitz:

That's interesting. Now it's mass-produced and available at hospital suppliers off the shelf, but you actually went in and did custom units in these various operating theaters?

Minter:

Yes. We went to Chicago and I think we went once or twice to the west coast, but we didn't do too much traveling. It was mostly done in the New York area.

Geselowitz:

What are some of the hospitals you did in New York?

Minter:

Montefiore was one we went to a lot, Beth Israel, downtown hospitals run by LIJ – the Long Island Jewish Medical Center. They had three hospitals and we were in all of them. There was another out in Amityville, and we set up one in Connecticut. I have forgotten the name of that hospital. We installed equipment in the hospital the President was taken to when he got shot. We were installing equipment there the day before, the hospital in Washington.

Geselowitz:

Really? It was in place and could have been used.

Minter:

Yes. We installed all the cameras and everything, put everything in place for them. We had many meetings in Baltimore. The hospital in Baltimore had big medical meetings and we set up more than one system there. We had one or two sessions in Philadelphia, but there was not much interest. There was heavy interest in Baltimore and we went there many times and set cameras up that are used all the time. They are used almost every day.

Aerospace

Geselowitz:

That was your medical engineering. What were some of the other interesting sidelights or other sort of technologies that you worked on in that period of the '60s and '70s? Did you do much with aerospace? That was a big period of advances in aerospace.

Minter:

We didn't really do an awful lot. We never got involved in aerial cameras. I bought an airplane and did my own flying. I come from Texas, and one of my farms in Texas that I inherited when my mother died is about two hundred acres – it’s a two-section farm. I had a landing strip in a field there. It's not active anymore. I flew to Texas in my plane a good many times. When my kids were young we used to take them along in the plane. Later, I had five kids and couldn't get them all in the plane. They were four years apart. I flew to Florida quite a bit on business and for pleasure, and flew around the eastern part of the country.

Leach:

Didn't you fly for the Civil Air Patrol as well?

Minter:

Yes, I was in the Civil Air Patrol.

Geselowitz:

When was that?

Minter:

That was after the war was over. We looked for people that might be lost in the woods. We flew regular special patterns so we could cover a large area quickly, and usually practiced on Saturdays. We found people occasionally but most of the time we had to set something up to look for it.

Geselowitz:

Is that why you got interested in the problem of detecting planes in the same altitude, from personal aviation experience?

Minter:

That's right. As a matter of fact, it was kind of surprising that no one ever thought of it before. It's such a simple thing. There are two antennas side by side vertically like this and you measure where it hits both at the same exact time. If it hits at the same time it's going to be in c plane at right abgles to the pair of close speed antennas.

Geselowitz:

Right.

Minter:

I built the unit and demonstrated it back on the 13th of December [2006] before the IEEE in New Jersey.

North Jersey Section of the IEEE, 1970s-2000s

Geselowitz:

Did you continue the sorts of activities you were involved with in the North Jersey Section during the '70s, '80s and '90s into the 21st century? Did it continue to be a place for people to exchange papers? Did it become more social? What was your relationship to the North Jersey Section of the IEEE during the last twenty to twenty-five years?

Minter:

I attended some of the meetings when they were interesting. I was not on any committees during that time, but I might have arranged for one or two papers from somebody I knew that had something to offer. However I was not as active in the Section. I was more active during the beginning.

Audio and Engineering Society

Geselowitz:

Do you want to say something about some of the other organizations in which you have been involved besides IRE and IEEE? I notice for example behind you a certificate from the Radio Club of America. What other groups have you been involved with professionally over the years?

Minter:

I was not a member of the Radio Club when I worked for the company in Boonton in 1934, but they all went to New York for meetings of the Radio Club at Columbia University. I went as a guest. Finally I became a member in '42. I helped to found the Audio and Engineering Society. In fact I was about the third president of the Audio and Engineering Society.

Geselowitz:

Do you remember when that was founded?

Minter:

I'm trying to think. I was always very interested in audio, and went to several meetings.

Geselowitz:

I see this reference to the banquet they had in '53. Were they headquartered in New York?

Minter:

Yes, they were. C. J. LeBell was very active in audio.

Geselowitz:

What did the audio engineers find in the AES that they did not find in the IRE that made them want to form a separate organization?

Minter:

I think the specialization of microphones, development not only of throat microphones but all kinds of tricky microphones such as for use under noise conditions. In the military there are quite a few applications for microphones. We worked in a number of different areas where microphones were used, and of course loudspeakers. When wideband audio came along the speakers and microphones both were improved. They had a very nice sound lab with test facilities in Murray Hill. It was one of the first I ever saw. At one of our first meetings the guy took us into the sound lab and showed us all the equipment they had for measuring audio and how beautifully dead it was. The walls and floor were all deadened. It was the most peculiar thing to be in a sound room and talk to somebody. We don't realize how much we depend on feedback. When you're in a dead room like that it's depressing.

Geselowitz:

Right.

Minter:

It's like being out in outer space, because nothing comes back. We don't realize how we expect to have comeback.

Geselowitz:

I am an alum of MIT also, and when I was there in the '70s Building 20 was still there. That was the building they built for the Rad Lab in World War II, and it had an anechoic chamber. It was not being used anymore for research but for storage. I went in there one time to get something, and if you drop something you don't get the sound cue that you are expecting. You're right. It's a very interesting experience.

Minter:

If you've been in a dead room, you know what I'm talking about. It's really dead.

Geselowitz:

Yes.

Minter:

And of course we could have problems. Equipment could generate noise unfortunately. We had things that would vibrate a little bit and had to figure out how to silence them. A cooling motor fan makes a noise. A lot of things had to be changed because sound got to be so important.

The body as an engineering system; blood pressure

Geselowitz:

Are there any other particular achievements that you have had over the years in your long and illustrious career on which we have not touched that you would like to mention?

Minter:

I'll mention one thing that I think is important. It's so strange that no one seems to publicize it. In 1992 Linus Pauling got two Nobel Prizes and a U.S. patent on this very important thing. Of course the human body pumps blood around and everything is run by blood. Just like a car runs on gasoline, a human body runs on blood. We all lubricate an engine - if you take lubrication out of an engine, it stops. It freezes up. He found out that the arteries are lined and have to be lubricated, and the lubrication is nourished by the amino acid lysine. That particular amino acid is essential for the lining to maintain itself. The liver is supposed to produce lysine, and the liver has to produce a lot of other things. Unfortunately the liver does not have any feedback system, so that if you need more lysine it can't tell that it needs to produce more. When you don't have lysine this coating on the arteries has to break up. And the craze is to figure how to get the breakup out. They don't realize they ought to fix the source. I found this out.

My wife's blood pressure was running high. I found that by giving her a very small amount of lysine – a little under the tongue as a powder or about a quarter of a teaspoon in a cup so she could drink it – and within 30 minutes she didn't have anymore trouble breathing. The arteries that are in the lungs are very small and they can clog up very quickly. I found this never fails. I had high blood pressure a couple of times. Why do you get high blood pressure? The brain is calling for help someplace and all it can do is increase the blood pressure. When this lubrication problem is solved by nourishing the lining of the arteries properly there is no problem and the blood pressure drops. In fact my wife's blood pressure dropped down to 113-115 from 160-165.

Geselowitz:

Is lysine available commercially?

Minter:

That's the amazing thing. Yes. Very inexpensive. You could pay $15 for enough to last you a whole year. It takes so little of it. I have told doctors about this. Recently a guy came out with a big brochure talking about the fact that even since 1992 this very important thing that we need, lysine, has been neglected. Lysine has no taste. You can buy it as a pill. I don't like pills, because pills have stuff you don't need and are chalk and don't dissolve right away. The powder dissolves instantly. A little under the tongue will carry this to various parts of the body almost instantaneously.

Geselowitz:

Have you thought about this at all from an engineering point of view?

Minter:

The body is an engineering system. It's taking care of everything by being pumped someplace. The brain is trying to do something about it. For example, my wife fell and damaged the part of her brain that determines balance and she lost her sense of balance. Since then she can't bend over to pick something up off the floor. She falls. She has to feel where she's going. Now she has to have a wheelchair or cane to get around. That's a practical application.

Geselowitz:

The Engineering and Medicine Biology Society is one of the constituent societies of IEEE that is growing very rapidly, and it turns out the body is an electromechanical system. The blood is mechanical, but it is controlled by electrical impulses in the system.

Minter:

I look at it like this - the brain is running the thing remotely. If there's something down here, it calls for more blood. If your foot hurts, it calls for more blood at the foot. If the blood can't get there, the heart pumps harder to get it there. It's simple.

Geselowitz:

That sounds really true.

Recent IEEE activities

Geselowitz:

Is there anything else you would like to say about your interaction with the IEEE North Jersey Section today? It had its 50th anniversary relatively recently and you were honored as the founding chair. Do you have much opportunity today to interact with the Section?

Minter:

I haven't been as active as I was in the past I guess.

Geselowitz:

No one expects you to be quite as active at this point in your career.

Minter:

In the very recent past my wife has been sick in the hospital so I have been tied up with my wife for the last few months. I did give a paper back on the 13th of December.

Geselowitz:

Right. About your new invention, which is very exciting.

Minter:

Yes.

Leach:

2004 and 2006.

Geselowitz:

You can still get him to come and talk.

Leach:

Sure.

Geselowitz:

I hope I will get invited to the next one and hear it firsthand. Howard, is there anything that you think I forgot to cover that you'd like to see covered as the Section Historian?

Aerospace; high-voltage power supplies

Leach:

Jerry, as far as aerospace, I know you were involved in some other things like high-voltage power supplies.

Minter:

That's right. Of course they use high voltage for many things. High voltage is required for all our big projection systems and we have high voltage even in the medical field. It can be used for sterilization. We say "high"; it's relatively high. It's not thousands of volts, but maybe hundreds of volts per inch. We want to be able to measure voltage without changing what is being measured. This means a very sensitive meter is required. Therefore, we helped to develop a sensitive voltmeter for measuring field strength. In fact that's how we got in the connector business. We were supplying these field strength meters to the Goddard Space Flight Center and others, and that led us into the business of making the connectors. We made a lot of field strength meters. It is just a wideband radio receiver with calibrated volts and microvolts, and we made various adapters to hook it up to various things. For example in an automobile to check the voltage on a sparkplug or where it's going with a sparkplug or to reduce ignition system interference. We spent a lot of time with the automotive people on control of ignition, noise suppression and instrumentation for it. There was some of that in the military field for the aircraft - specialized interference problems in aircraft and aircraft systems, and we helped some of the aircraft people with test gear.

Leach:

Did you get into specifying resistor sparkplugs or special—?

Minter:

That's one solution, is to try to redesign the equipment. And one must be careful not to degrade anything by doing that. You don't like to put something in that will be a compromise in performance. One of the worst things in flying a plane is when something goes bad while you're in midair and you can't fix it. You want to make it as simple as possible. We designed resistors, for example, that could withstand changes in pressure but could also withstand moisture. Planes frequently get moisture condensation in clouds, so we had to have things that could withstand the moisture and still function.

Leach:

Some of your high-voltage power supplies were utilized in the NASA probes and satellite probes.

Minter:

That's right.

Leach:

DIGI-KLIPS® were involved with the aerospace missiles and DC-10 aircraft as well. And of course you are still going on with those.

Minter:

That's right.

Geselowitz:

Your technology has been in almost every sector.

Minter:

Yes. Pearl Harbor had some of our aircraft detectors in it probably that we built.

Coil work thesis, MIT

Leach:

Would you like to mention the thesis you developed in coil work at MIT?

Minter:

I had kind of a tough time with the thesis. We didn't have a Q meter in those days. It was difficult to measure the quality of anything. We had meters that measured distance, capacitance and inductance but they were too big physically to measure the things we wanted to measure in many cases. We got involved quite a bit in technology trying to measure small things. What's the inductance of a plate of material? It gets to be complicated. The technology for making measurements of the impedance of an aircraft wing for instance. There are many complicated measurements and we tried to figure out a way to get around the difficulties. We built some test gear, and that's how we came to contact the Goddard Space Flight Center. They were having trouble making measurements, so we supplied test gear. We worked with many other companies – GE in Schenectady, and we worked with people just north of Boston. I've forgotten the name of the company now, but we worked with them a lot particularly during the war. They are out of business now. Didn't do much at MIT, as I mentioned earlier, because they were all worried about security.

Measurements Corporation equipment

Leach:

Another question about the Measurements Corporation just before you sold it. I'd like to ask you about the types of equipment that you were making at that time. There were the signal generators, the voltmeter and the griddip meter. Were there other devices as well, test equipment?

Minter:

We made meters measuring the signal strength in the air from a signal. In other words, to determine how well an antenna was working we would measure the signal strength in microvolts to measure its pattern. What they were essentially were very well calibrated receivers.

Geselowitz:

At the time you sold the company you were one of the major manufacturers of these kinds of meters and test equipment in the country.

Minter:

That's right.

Charles Edison and Henry Ford

Geselowitz:

I want to ask one last thing before we close for today. You mentioned earlier that when you sold the company to the Edison Company you did not at that time meet Charles Edison, the grandson of Thomas Alva Edison and Governor of New Jersey. However, you alluded that you knew him later. I would love to hear that story of how you met Governor Edison.

Minter:

He was living in New York at the Waldorf Astoria. He had a personal secretary who came to me one day and said, "The boss wants to talk to you." He had nothing to do with our business. He was out of the company altogether. He was just on the outside. I said, "Sure. Who's the boss?" She said, "The former Governor" and I said, "Oh sure," and I went to New York. He had no children. It was kind of funny. He started talking about old times – things that happened when they were working with Ford and the trouble he had with Henry Ford. I never knew Ford did these things.

Leach:

Charles was the son of Thomas Edison.

Minter:

He was the son. He started showing me his portfolio, all the stock he had and stuff like this. We were talking generally, and then we talked in detail about Henry Ford. Ford wouldn't let anybody sit down. Everybody had to stand up. One day Ford came in the front office and the telephone switchboard service guy was sitting on a stool. He kicked the stool out from under the guy. The telephone company cut off his phone service and said, "You apologize or you don't have phone service." They'd go out together fishing, Charles Edison and Henry Ford. They were pretty good friends that way. Finally one day Ford said, "Why don't you make batteries for us?" Edison made a very good quality battery. The battery was made not out of iron but nickel and they would last. It was a military type battery really made for continuous use under bad conditions.

Ford gave him an order for batteries. They made some batteries and sent them out and they got rejected. Edison said, "I went out to see what was wrong and came back and made some more. They went out and got rejected again." He said, "I finally went out to see Mr. Ford himself." He said "Look Mr. Ford, we have a purchase order from you for batteries. We sent batteries out several times and they've been rejected. What is wrong with the batteries?" and Ford didn't answer him. He didn't give any response. Edison finally just gave up, cancelled the order and forgot about it. He said, "We never could find out why they wouldn't accept our battery." He said, "We didn't have a very good experience with him as a supplier. We tooled up for this thing and made a whole plant – we built a building – and set up a complete line. We sold it finally and got rid of it. We didn't want to build batteries. We were making batteries at one time just for the people that wanted a nickel battery that would last indefinitely." They put them on railways. All the railway batteries were nickel so they wouldn't have to worry about a battery going bad on a train. It cost more money, but they didn't need very many of them. And of course they made them for the military.

Geselowitz:

Edison told you these stories, so you had a direct connection through Governor Edison to Thomas Edison and Ford.

Minter:

Yes. He said they had a very tough time with Ford. Very tough.

Geselowitz:

It was also nice to have a phone monopoly where the phone company could tell him what they did.

Minter:

I have another story. During the war I made equipment for other companies, and one of them told me some stories about experiences that they had with Ford. The chief engineer at Ford – and I forget his name now – had a big boat. At the Mackinac Straits they had boat racing in the summer. He would invite a bunch of the guys out for boat races. They were all Ford flunkies that came out to run the sails. One time Ford was along with them. The guy said, "We made a sharp turn and a guy fell overboard. We stopped to pick him up and Ford raised hell." Ford yelled, "What are you stopped for? We're going to lose the race, we're going to lose the race."

Geselowitz:

That's the reputation that he had.

Minter:

That's firsthand knowledge.

Geselowitz:

That's a great story.

Sale of Measurements Corp. to Edison Company

Leach:

Did you have dinner at the West Orange Laboratory?

Minter:

Yes, we had dinner there.

Leach:

Did you have dinner with the former Governor?

Minter:

No. He didn't have anything to do with the company then.

Geselowitz:

The Edison Company that you sold your company to still owned West Orange. It was before they gave it to the government and it became a national park.

Minter:

Yes. I had dinner down there. That was kind of interesting. We had dinner in the Edison home on the hill. It was a big, big home. I think it was the very last big dinner. All of our directors were there, and we had our final settlement in that factory dining room.

Geselowitz:

Now you can tour it. It's part of the national park service.

Thomas Edison anecdote

Minter:

I've got a funny story. I can't remember the fellow who was representing Edison at the time, but a guy from Edison was standing out in front of the plant one day. He said, "I've got to tell you a story. We had a fire one time, many years ago, and we had all our stuff inside." It was a standards and lab fire. They brought out the units from the standards house so they wouldn't burn. He said, "The Governor himself was here. He was not Governor then, but he was active. Thomas Edison was watching the fire and said, 'Call your mother to come out and see this fire. Call your mother'." He was just like a kid out there watching the fire.

Leach:

This was Edison?

Minter:

This was Edison himself, yes. His son told me this.

Geselowitz:

That was Thomas Edison doing that.

Minter:

Yes. At the first he was out front watching and saying, "Tell your mother to come down and see us."

Geselowitz:

That's a great story, Jerry. Thank you very much.

- People and organizations

- Engineers

- Corporations

- Engineering and society

- Military applications

- World War II

- Computing and electronics

- Instrumentation

- Bioengineering

- Communications

- Radio communication

- TV

- Signals

- Signal generation & recording

- Electronic components

- Connectors

- IEEE

- Geographical units

- Prominent members

- Transportation

- Aerospace engineering

- News